Liquid resistor loading device

A technology of load device and liquid resistance, which is applied in the field of testing load resistance of power supply equipment, can solve the problems of high investment cost, low power, and inability to meet the requirements of electrical performance testing, and achieve the effect of improving continuity and reducing investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

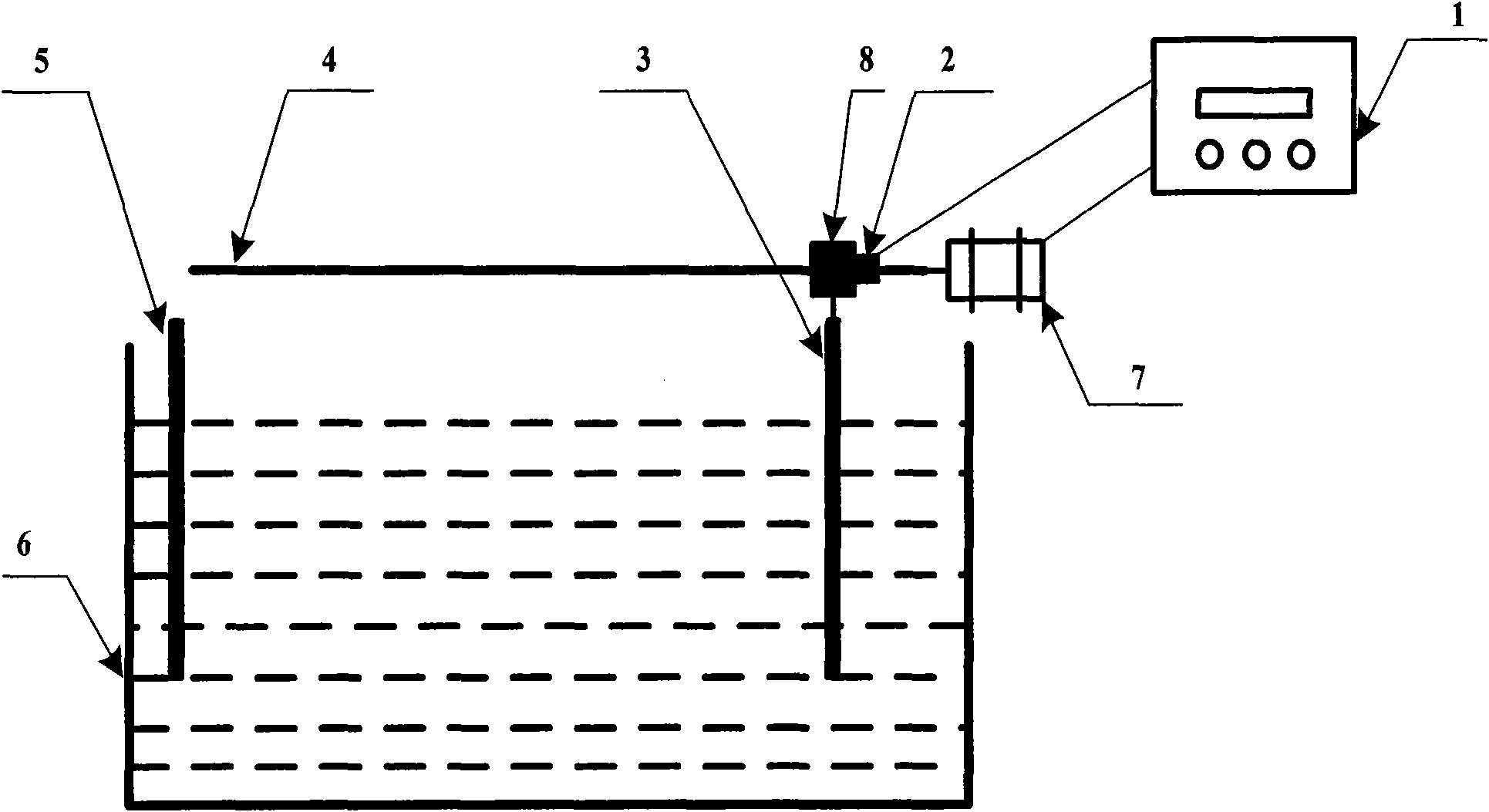

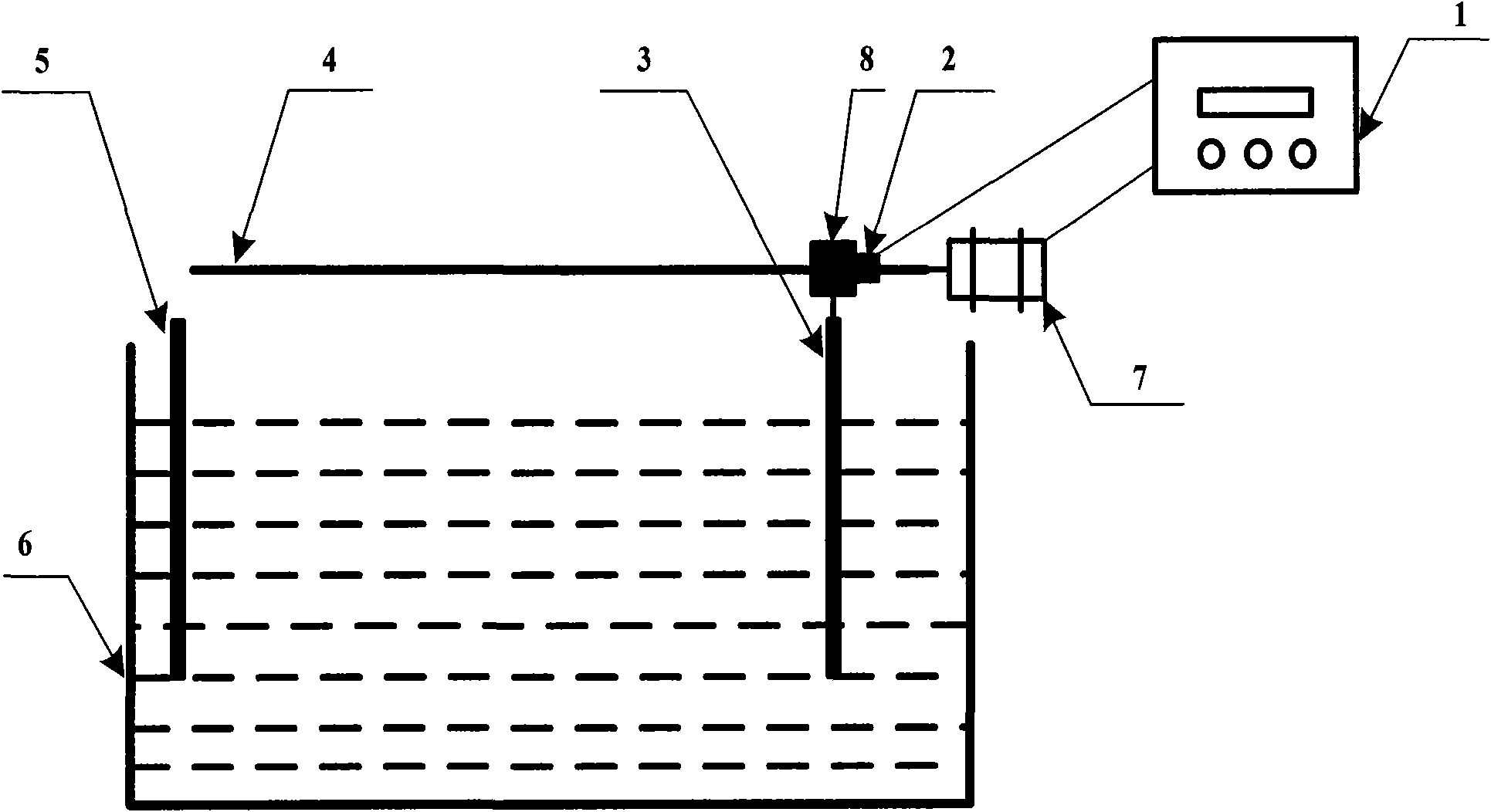

[0015] Such as figure 1 As shown, the controller (1) controls the drag motor (7) to rotate, the drag motor (7) drives the drive screw (4) to rotate, and the drive screw (4) is driven by the thread to drive the slider (8) to move left and right , Move the movable electrode plate (3) in the liquid resistance box (6) left and right. The controller (1) compares the signal of the position sensor (2) with the set value, and judges whether the position of the movable electrode plate (3) is appropriate. When the position of the moving electrode plate (3) deviates to the direction of the fixed electrode plate (5), the controller (1) controls the drag motor (7) to rotate forward to make the moving electrode plate (3) move away from the fixed electrode plate (5) Move; when the position of the moving electrode plate (3) deviates away from the fixed electrode plate (5), the controller (1) controls the drag motor (7) to rotate in reverse, so that the moving electrode plate (3) approaches th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com