Device for compacting road paving materials

An equipment, road technology, applied in the field of equipment for compacting road paving materials, which can solve problems such as increased maintenance needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

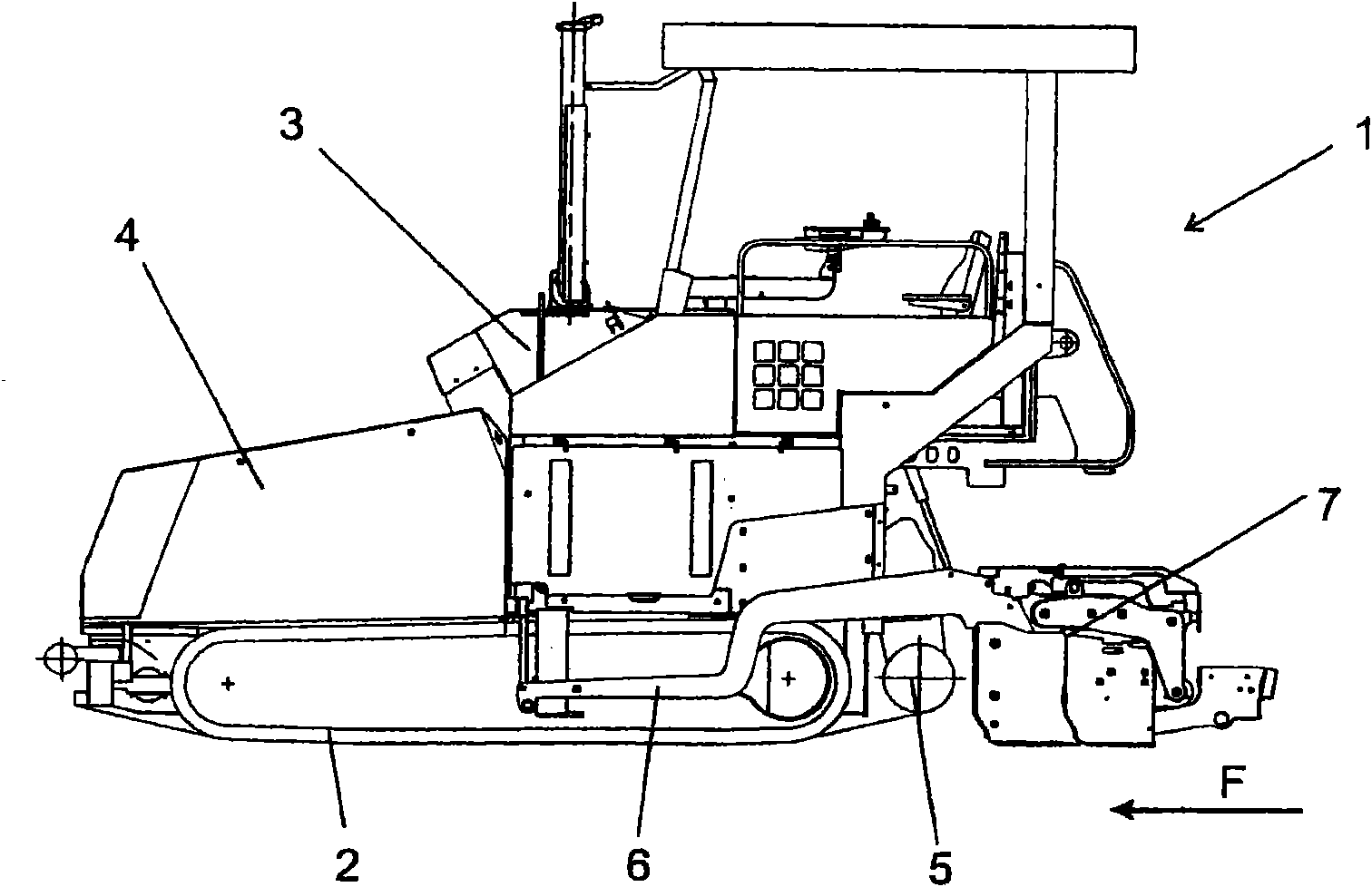

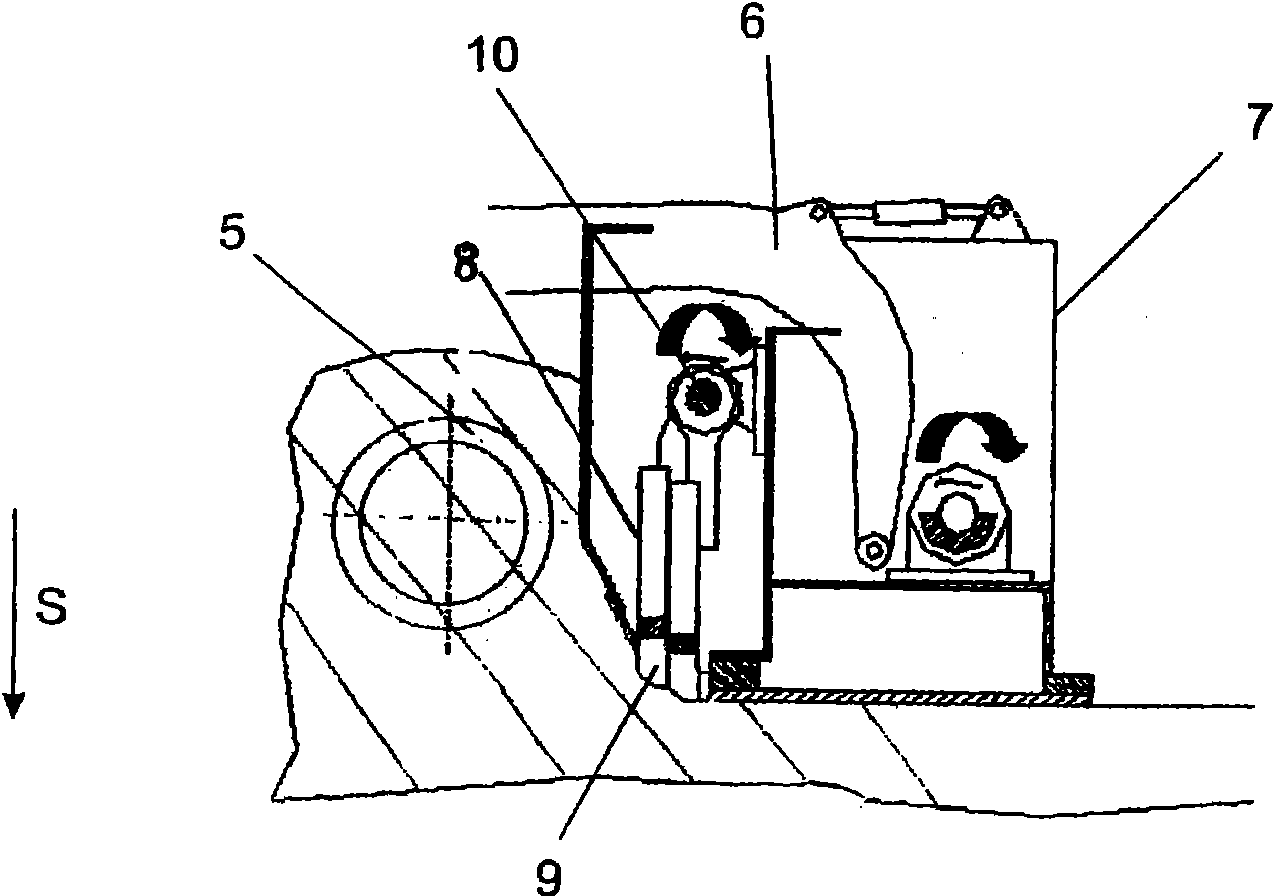

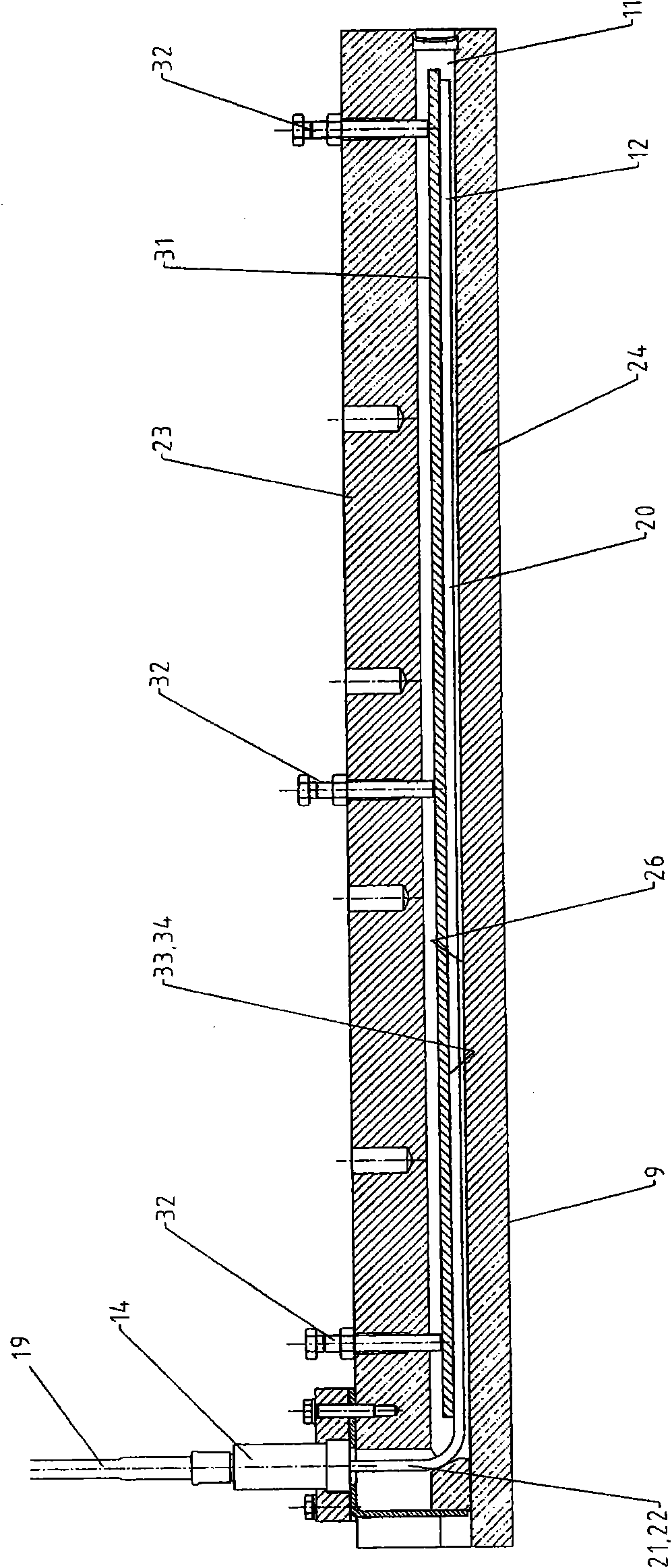

[0022] conform to Figure 1a The road paving and leveling machine 1 includes a chassis 2, a drive unit 3, a material hopper 4 located at the front in the direction of travel, and a distribution auger 5 located at the rear. The transverse arm 6 is used to pull the screed beam 7 which level the surfacing material conveyed rearwardly from the material hopper 4 and distributed by the distribution auger 5 . The screed 7 is preferably a vibratory screed for smoothing and compacting. At least one compactor 8, in Figure 1b , is arranged next to the paving screed beam 7 at the front in the direction of travel F. according to Figure 1b , two tamping machines 8 are arranged next to each other. Thus, a double compactor leveling beam is formed. Furthermore, a compactor 8 can also be arranged downstream of the leveling beam 7 . The screed beam 7 can have a fixed working width, or can extend transversely as an extended screed beam for a larger working width. A compactor 8 arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com