Heating system of power battery of pure electric automobile and control method thereof

A technology of pure electric vehicles and power batteries, applied in electric vehicles, battery temperature control, secondary batteries, etc., can solve the problems of consuming battery power, affecting vehicle power and driving range, etc., and achieves simple control methods and expanded The effect of using range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

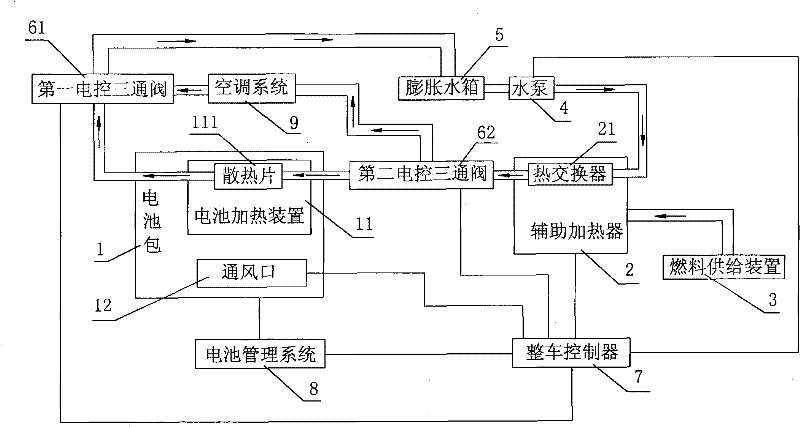

[0023] Such as figure 1 As shown, the heating system of the pure electric vehicle power battery in this embodiment includes a battery heating device 11 installed in the battery pack 1. The battery heating device 11 is provided with a hollow cooling fin 111, and the cooling fin 111 is provided with a water inlet and a water outlet. , the heating system also includes an auxiliary heater 2, the auxiliary heater 2 is connected with the fuel supply device 3, the auxiliary heater 2 has a built-in heat exchanger 21, and the water inlet of the heat exchanger 21 passes through the water pump 4 and the water pipe and the expansion tank 5 The water outlet of the heat exchanger 21 communicates with the water inlet of the air conditioning system 9 and the water inlet of the cooling fin 111 through the second electronically controlled three-way valve 62, and the water outlet of the air conditioning system 9 and the outlet of the cooling fin 111 The water port communicates with the water inl...

Embodiment 2

[0035] Such as Figure 5 As shown, the heating system of the pure electric vehicle power battery in this embodiment includes a battery heating device 11 installed in the battery pack 1. The battery heating device 11 is provided with a hollow cooling fin 111, and the cooling fin 111 is provided with a water inlet and a water outlet. , the heating system also includes an auxiliary heater 2, the auxiliary heater 2 is connected with the fuel supply device 3, the auxiliary heater 2 has a built-in heat exchanger 21, and the water inlet of the heat exchanger 21 passes through the water pump 4 and the water pipe and the expansion tank 5 The water outlet of the heat exchanger 21 communicates with the water inlet of the cooling fin 111 through the electric control valve 6, and the water outlet of the cooling fin 111 communicates with the water inlet of the expansion tank 5. The electric control valve 6, auxiliary heating The device 2 and the water pump 4 are connected to and controlled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com