Solid wood floor with grooves on sides, and floor keel thereof

A solid wood flooring and flooring technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of wasting wood and splicing gaps, etc., achieve a large cost advantage, eliminate gaps, and avoid waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

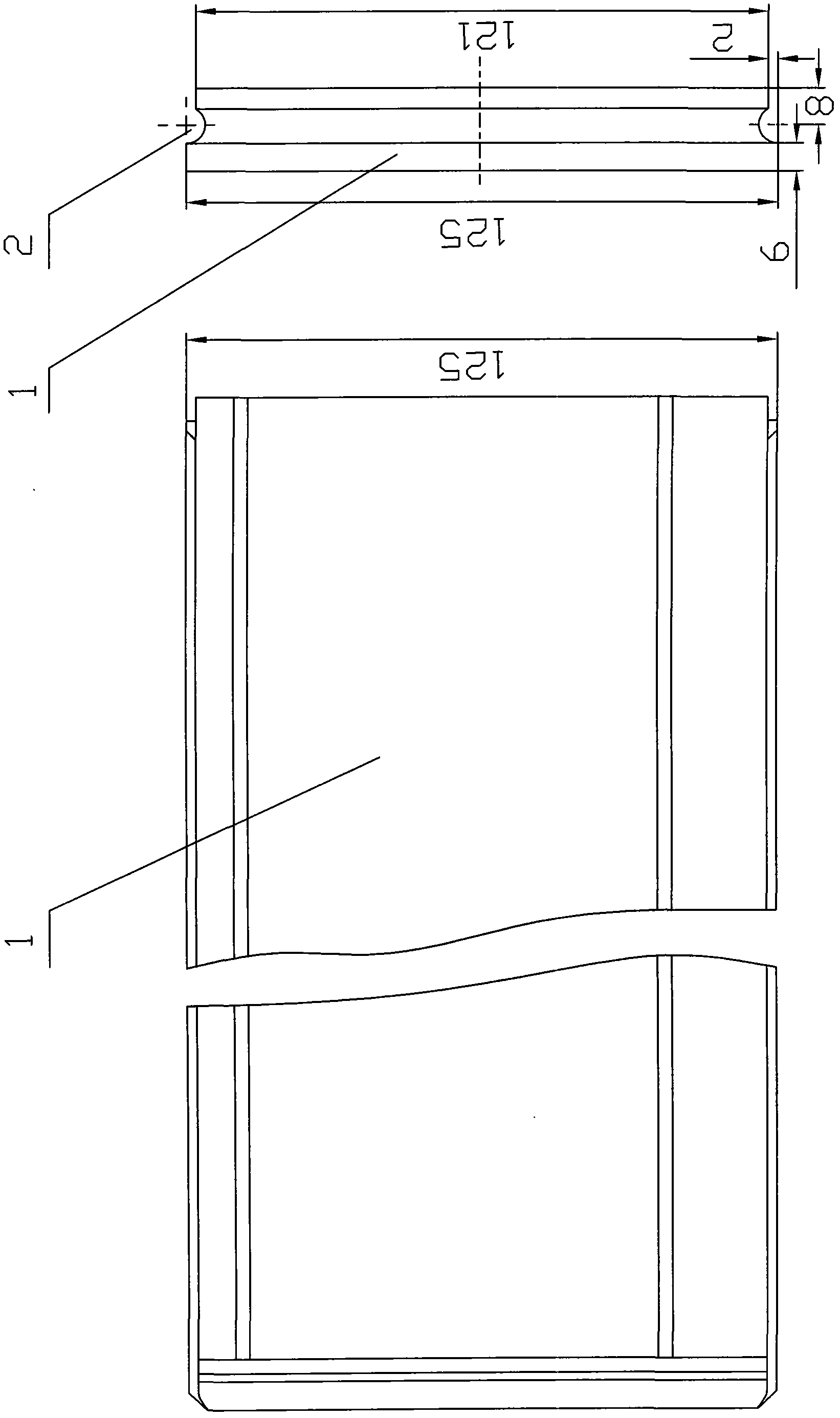

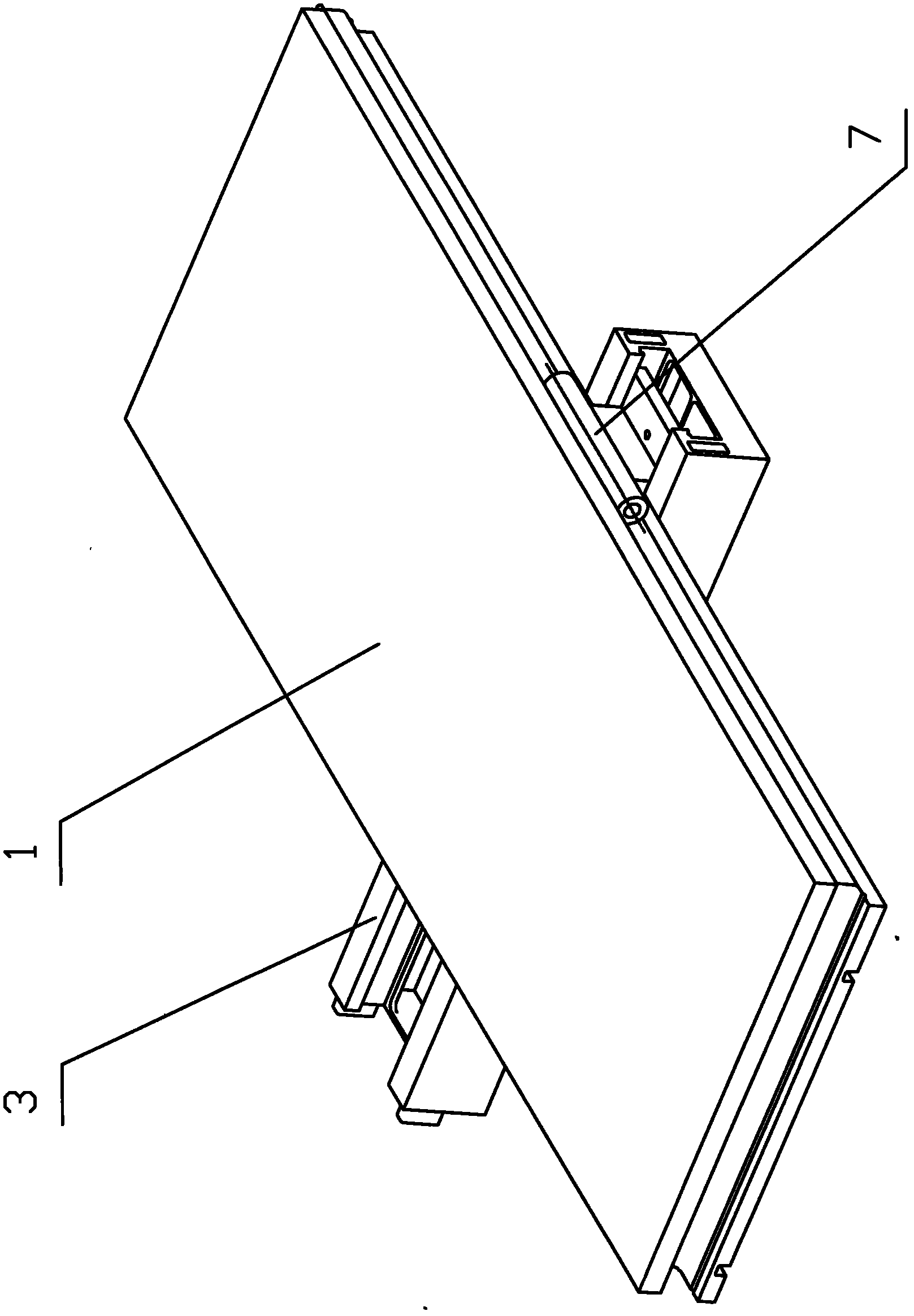

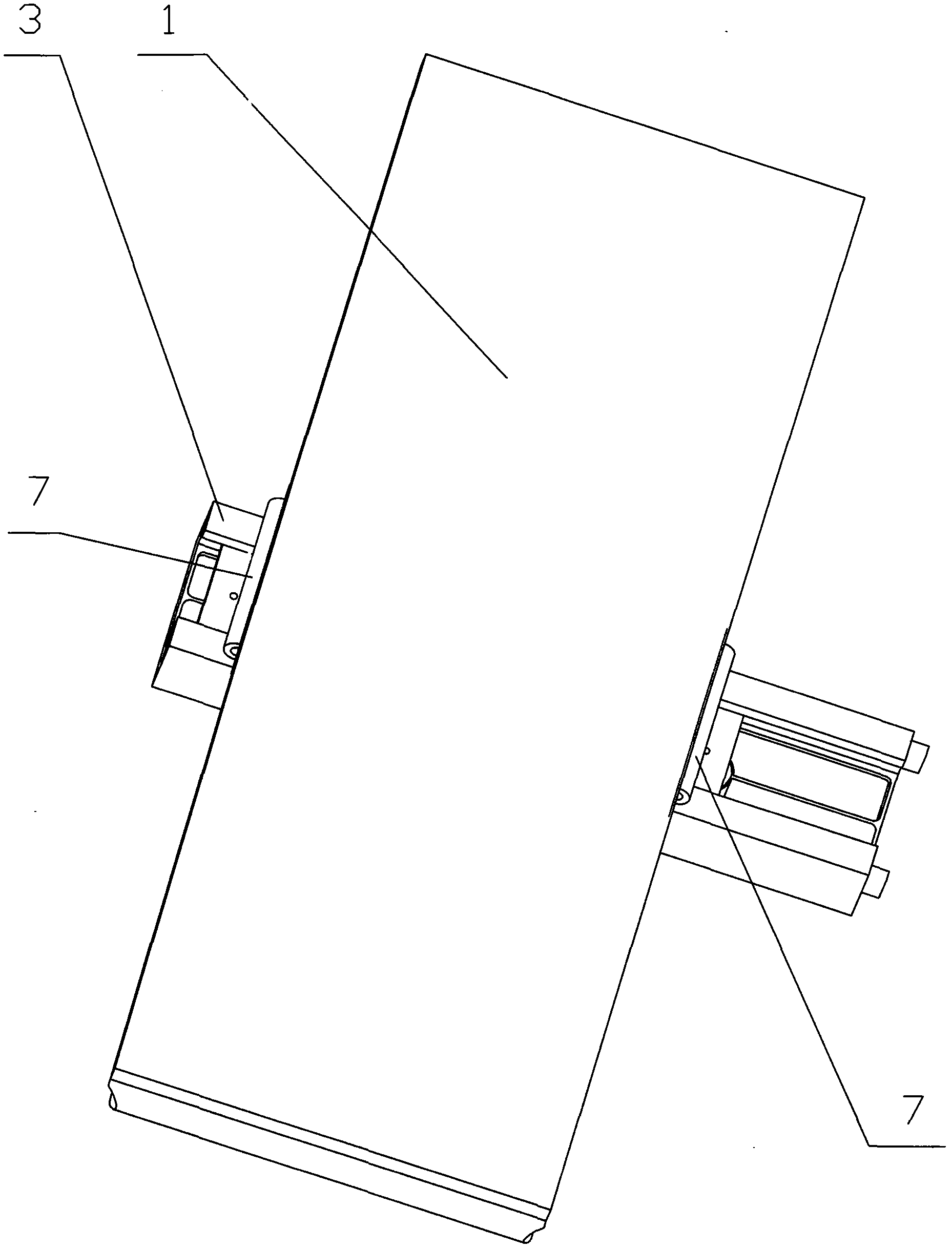

[0028] Such as figure 1 As shown, taking a conventional solid wood floor with a width of 125 mm and a thickness of 18 mm as an example, the side grooved solid wood floor of the present invention has parallel and symmetrical parallel grooves 2 parallel to the board body 1 on both sides of the board body 1. Groove 2 is arc groove (also can be square groove, triangular groove, trapezoidal groove etc.), and the radius of arc groove is 4 millimeters, and the center of circle is 8 millimeters away from plate body 1 bottom surface, and the width of plate body 1 above arc groove is 125 mm, The width of the plate body 1 below the arc groove is 121mm. The side slotted solid wood floor of the present invention is equipped with a special floor keel, such as figure 2 , image 3 As shown, the floor keel of the present invention is a long bone bar 3 that is clamped and connected, and the actual length of the bone bar 3 is determined according to the processing cost. Generally, a board bod...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap