Air extracting device for electroplating equipment

A technology of electroplating equipment and air extraction device, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of easy accumulation of cooling water, consumption of electric power resources, affecting the air extraction effect, etc., and achieves good air extraction effect, cost saving and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

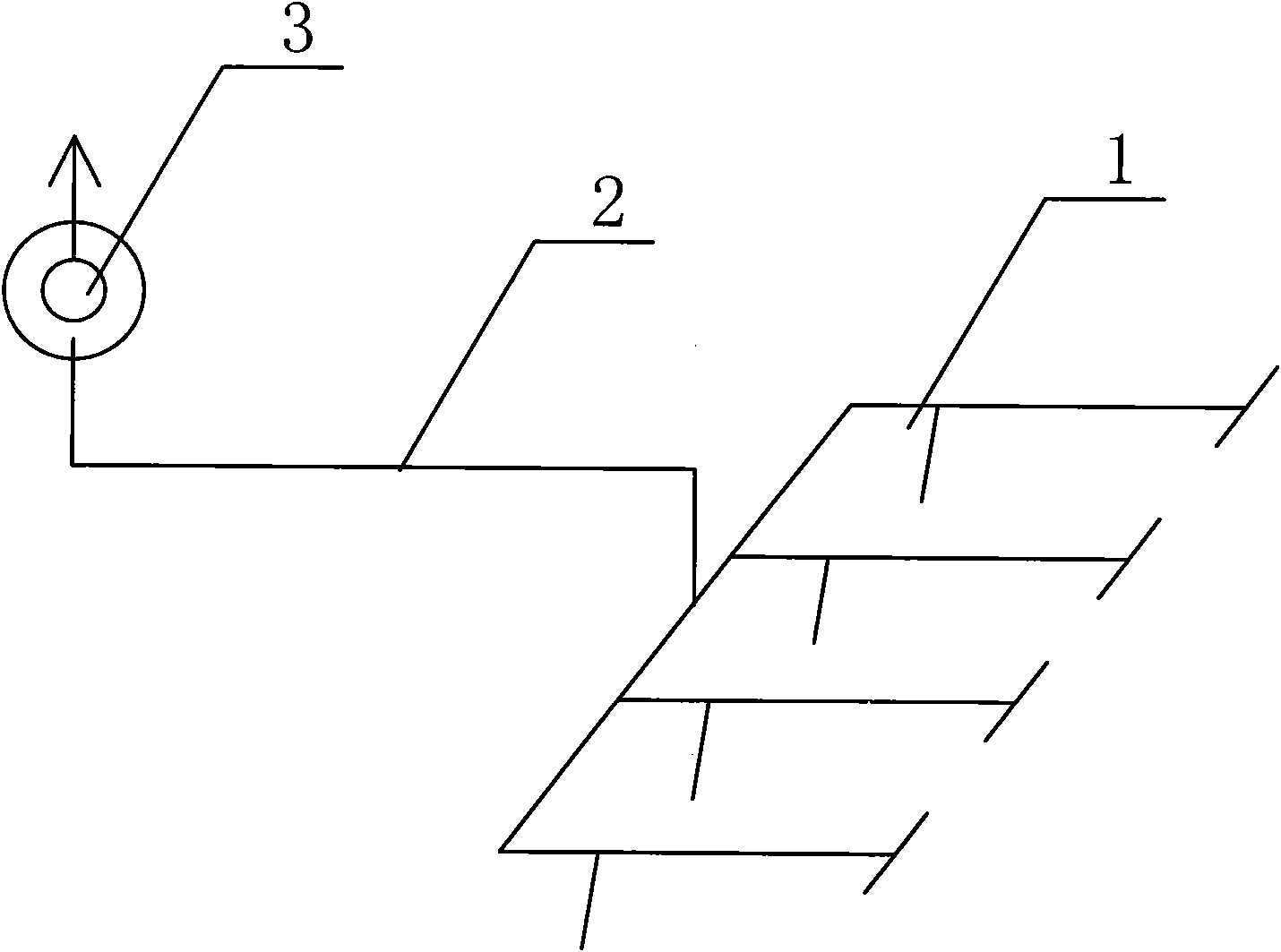

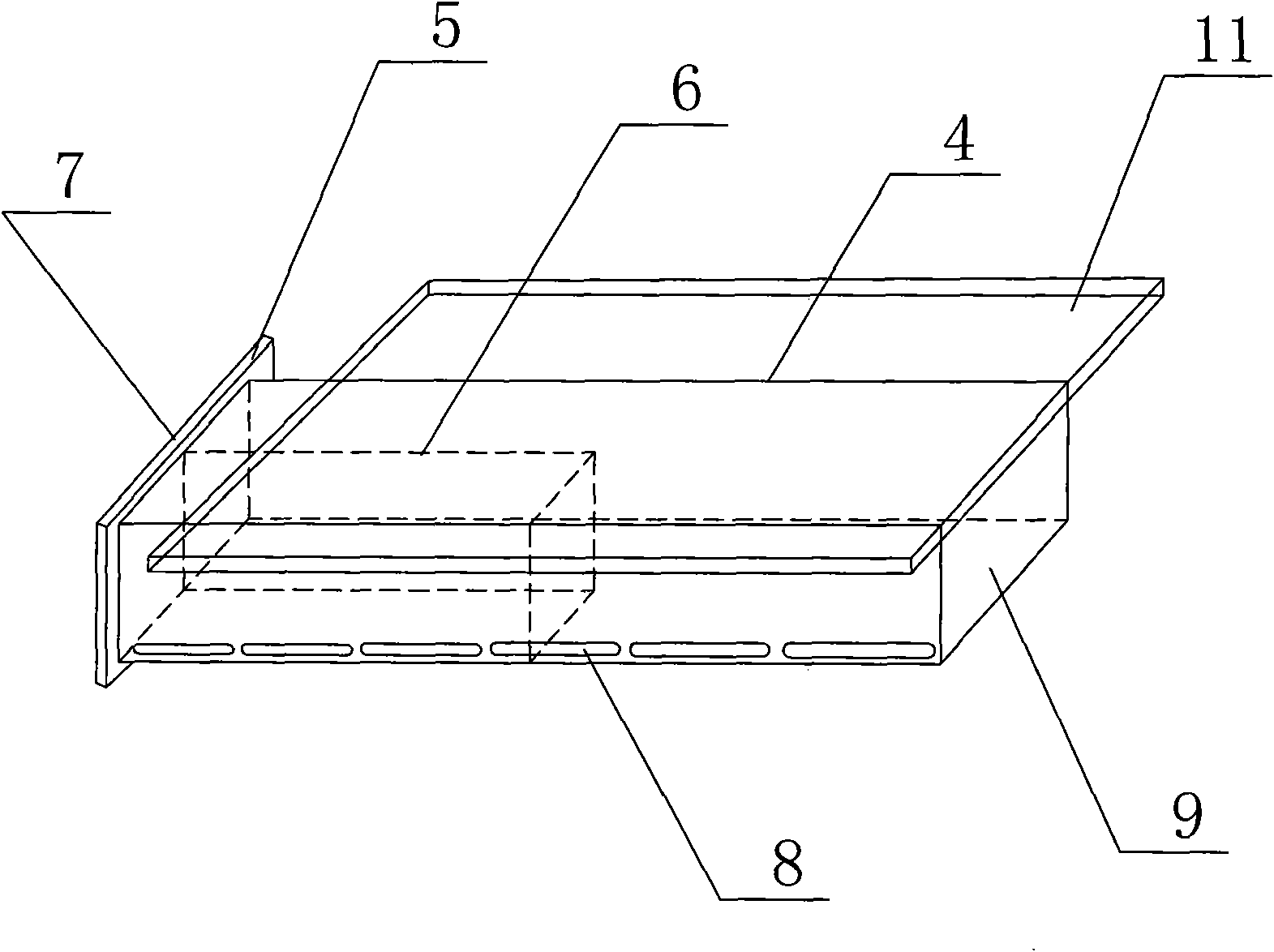

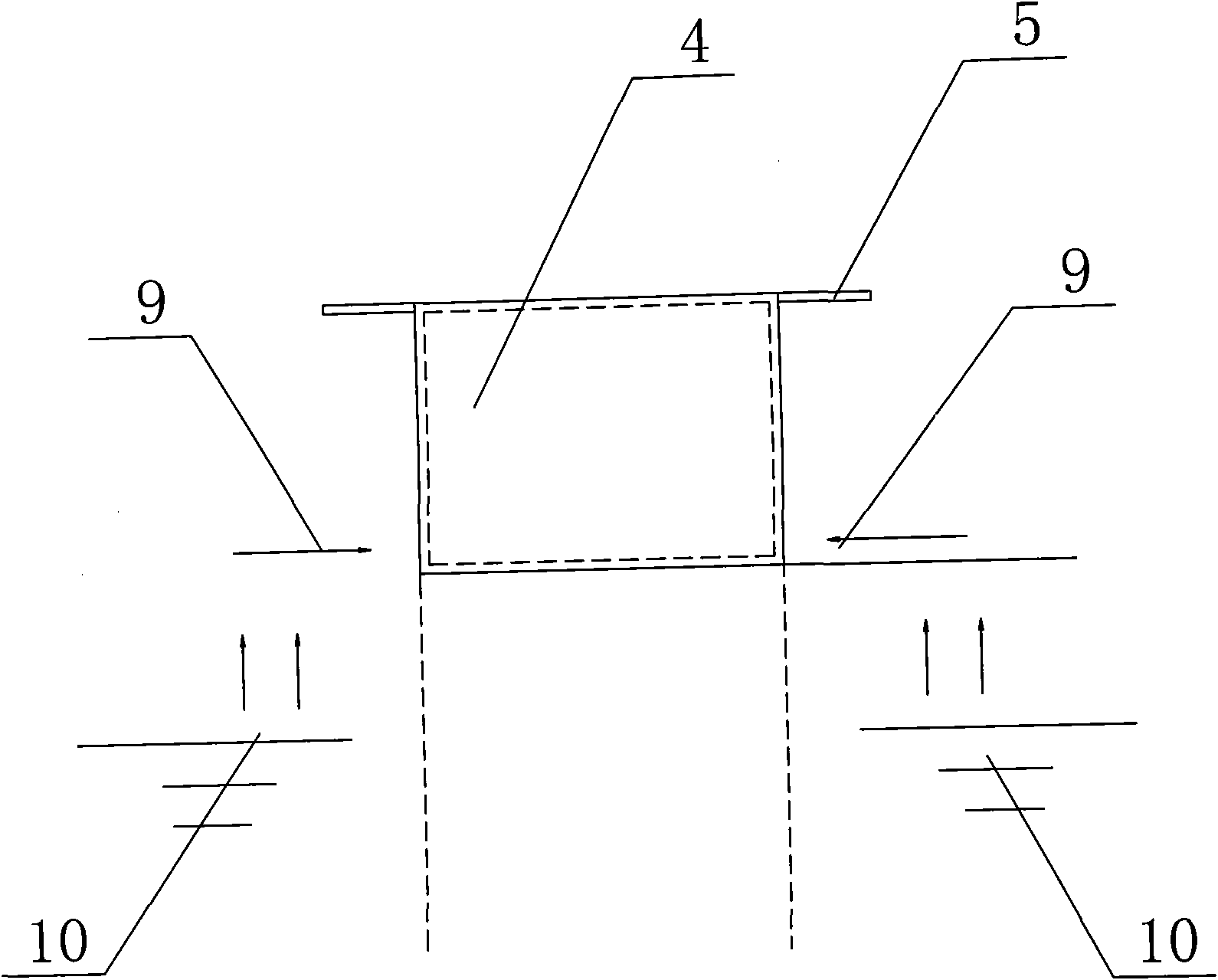

[0015] see Figure 1 to Figure 3 As shown, in this embodiment, an air extraction device for electroplating equipment, which is assembled on the electroplating tank 10 of the electroplating equipment, includes an air extraction hood 1, a fan 3 and an air extraction main branch pipe 2 connected between the two. The main exhaust branch pipe 2 is connected to the fan 3 in an upward slope, which avoids the accumulation of cooling water in the exhaust main branch pipe 2 and affects the occurrence of the ventilation effect. The pipe 4 is provided with an air outlet 7 and an air inlet 9, and the air outlet 7 of the exhaust pipe 4 extends to both sides with auxiliary flow restricting plates 5. The auxiliary flow restricting plate 5 does not affect the entry and exit of the electroplating workpiece. , which can effectively prevent the exhaust gas in the electroplating tank 10 from emitting to the outside, and the air exhaust pipe 4 is provided with a deflector 6, and the deflector 6 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com