Method for prewashing multi-density double-setting long-sealing gas channeling prevention well cementing

An anti-gas channeling and pre-washing technology, which is applied in sealing/package, earthwork drilling, wellbore/well components, etc., can solve the problems of cement slurry weight loss, delay the time of weight loss, prevent lost circulation, and improve displacement efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1. This method is applied to well Puqian 189-14.

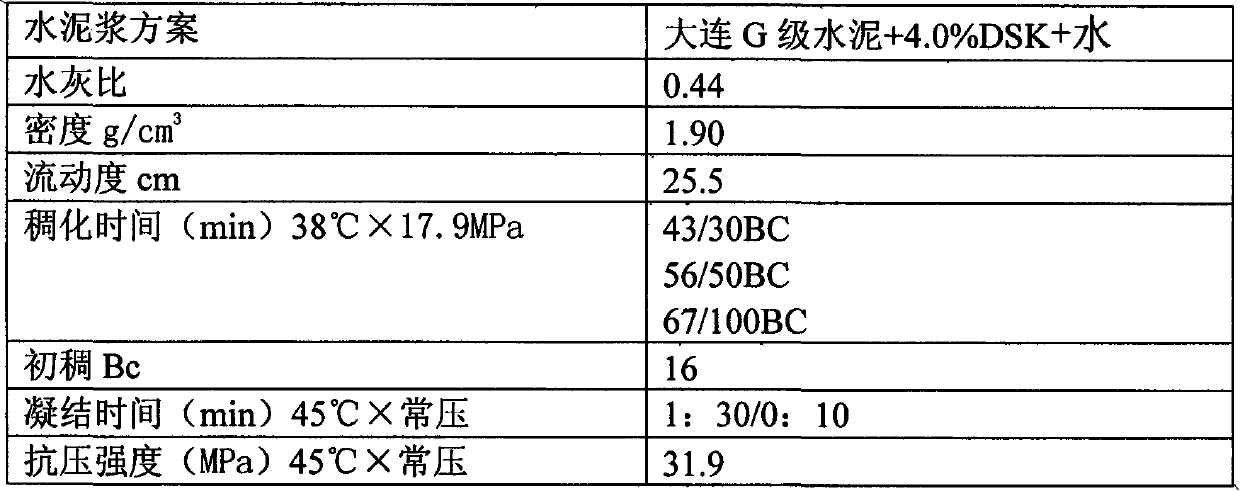

[0017] 1) Surface Table 3

[0018] name

Density (g / cm 3 )

Design consumption (m 3 )

Actual consumption (m 3 )

Spacer (water)

1.0

2.0

2.0

prewashed grout

1.80

5

6

G grade puree (0~60m)

1.90

4.5

32

Grade G+4.0%DSK(60-136m)

1.90

5.7

27

[0019] 2) Oil layer Table 4

[0020] name

Embodiment 2

[0021] Example 2, this method is applied to Puqian 205-20

[0022] 1) Surface Table 5

[0023] name

Density (g / cm 3 )

Design consumption (m 3 )

Actual consumption (m 3 )

Spacer (water)

1.0

2.0

2.0

prewashed grout

1.80

5

6

G grade puree (0~60m)

1.90

4.5

27

Grade G+4.0%DSK(60-136m)

1.90

5.7

27

[0024] 2) Oil layer Table 6

[0025] name

Embodiment 3

[0026] Example 3, this method is applied to Puqian 205-10

[0027] 1) Surface Table 7

[0028] name

Density (g / cm 3 )

Design consumption (m 3 )

The actual amount

(m 3 )

Spacer (water)

1.0

2.0

2.0

prewashed grout

1.80

5

6

G grade puree (0~60m)

1.90

4.5

28

Grade G+4.0%DSK(60-136m)

1.90

5.7

28

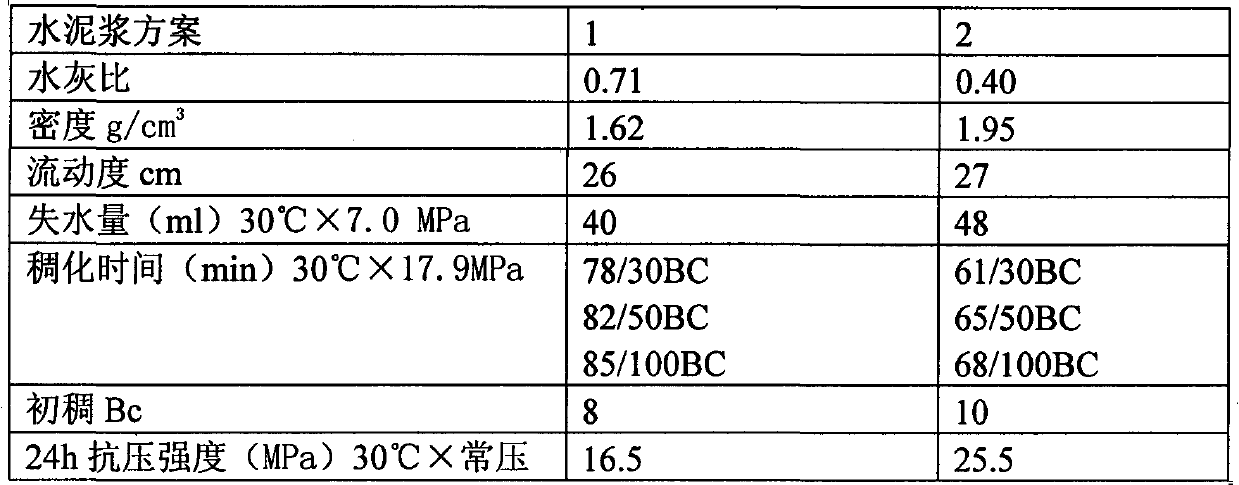

[0029] 2) Oil layer Table 8

[0030] name

Density (g / cm 3 )

Design consumption (m 3 )

Actual consumption (m 3 )

Spacer (water)

1.0

1.5

1.5

DZG flushing isolation fluid

1.50

5.0

5.0

prewashed grout

1.80

6

7.5

No. 1 cement slurry (ground-420m)

1.63

17

18.5

No. 2 cement slurry (420m-1200m)

1.92

26

26.5

[0031] In the construction of Well Puqian 189-14, Well Puqian 205-10 and Well Puqian...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com