Ironing table

An ironing table and three-dimensional weaving technology, which is applied to ironing pads, textiles, papermaking, knitting, etc., can solve the problems of decompression buffering, high cost, and weakened pad cushioning performance, and achieve good elasticity, high heat resistance, The effect of resurgence avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

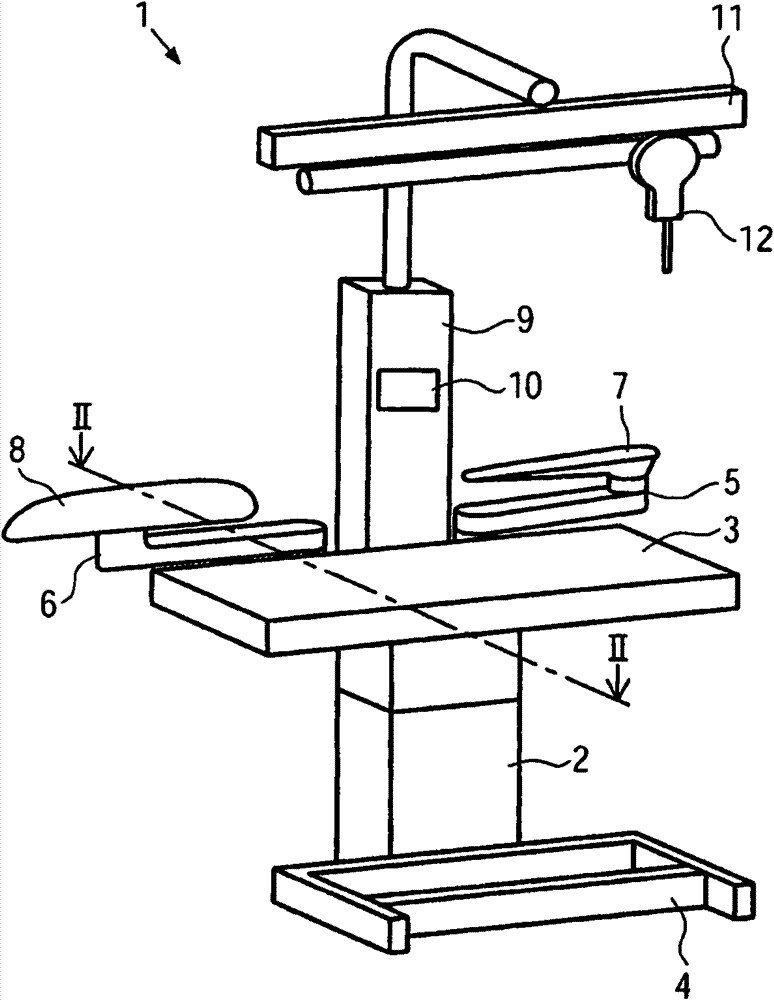

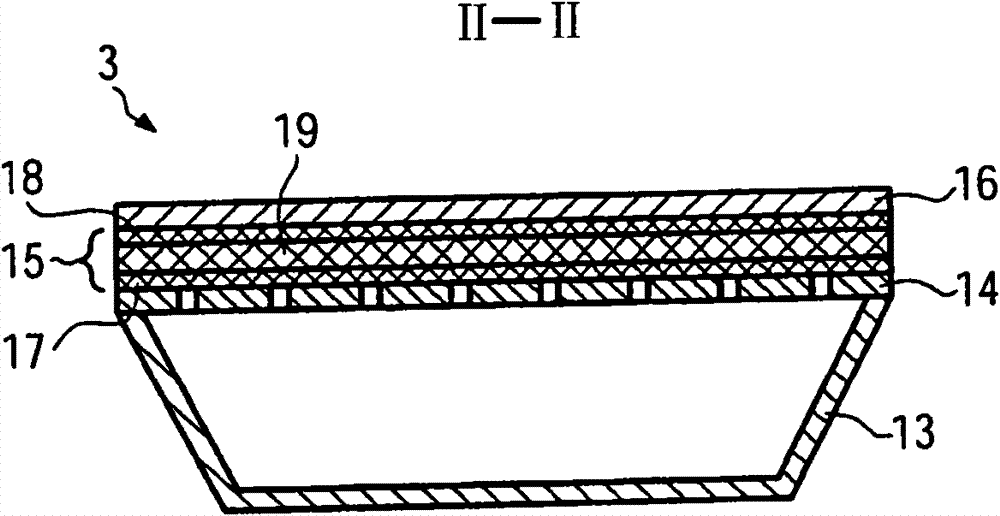

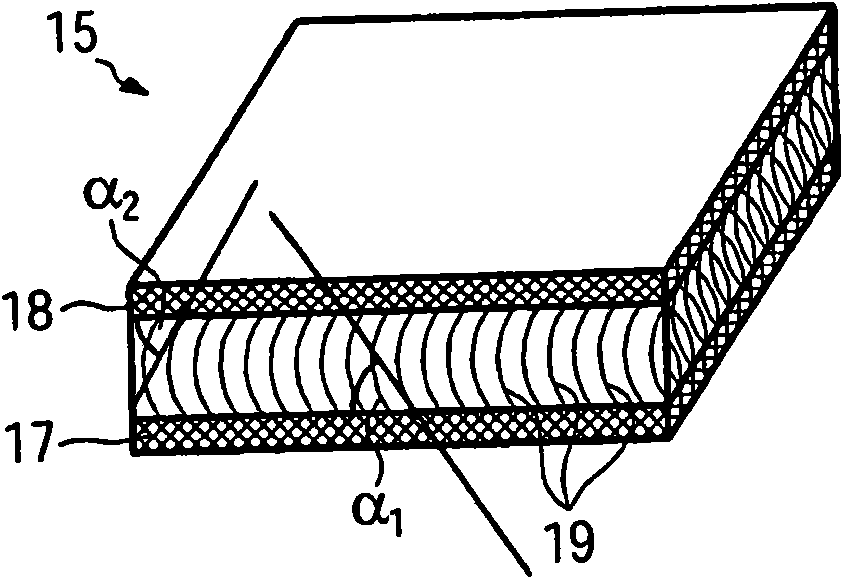

[0031] exist figure 1 An ironing table 1 according to the invention is shown in . The ironing table 1 comprises a base frame 2 in which a ventilation unit is arranged. The base frame 2 is connected to the ironing worktop 3 so that air can be sucked away from the ironing worktop 3 by the ventilation unit, or air can be blown into the ironing worktop 3 . The base frame 2 is also connected with a foot switch 4, through which the ventilation unit can be switched from air suction operation to air supply operation.

[0032] In addition to the ironing worktop 3 , the ironing table 1 can also have a plurality of swing arms 5 and 6 to which further ironing worktops 7 and 8 are fastened. The ironing worktops 7, 8 are smaller than the ironing worktops 3, eg for ironing shirt sleeves. The ironing worktops 7, 8 are likewise connected to the base frame 2, so that suction or blowing can also take place here.

[0033] The ironing table 1 is provided with an air duct 9 through which the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com