Hydraulic resistance type tall building escape device

A technology for escape devices and high-rise buildings, which is applied in the field of escape devices for high-rise buildings. It can solve the problems that affect the durability and reliability of escape devices, have no safe hiding place, and can only wait for rescue from others. It achieves light weight, small size, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

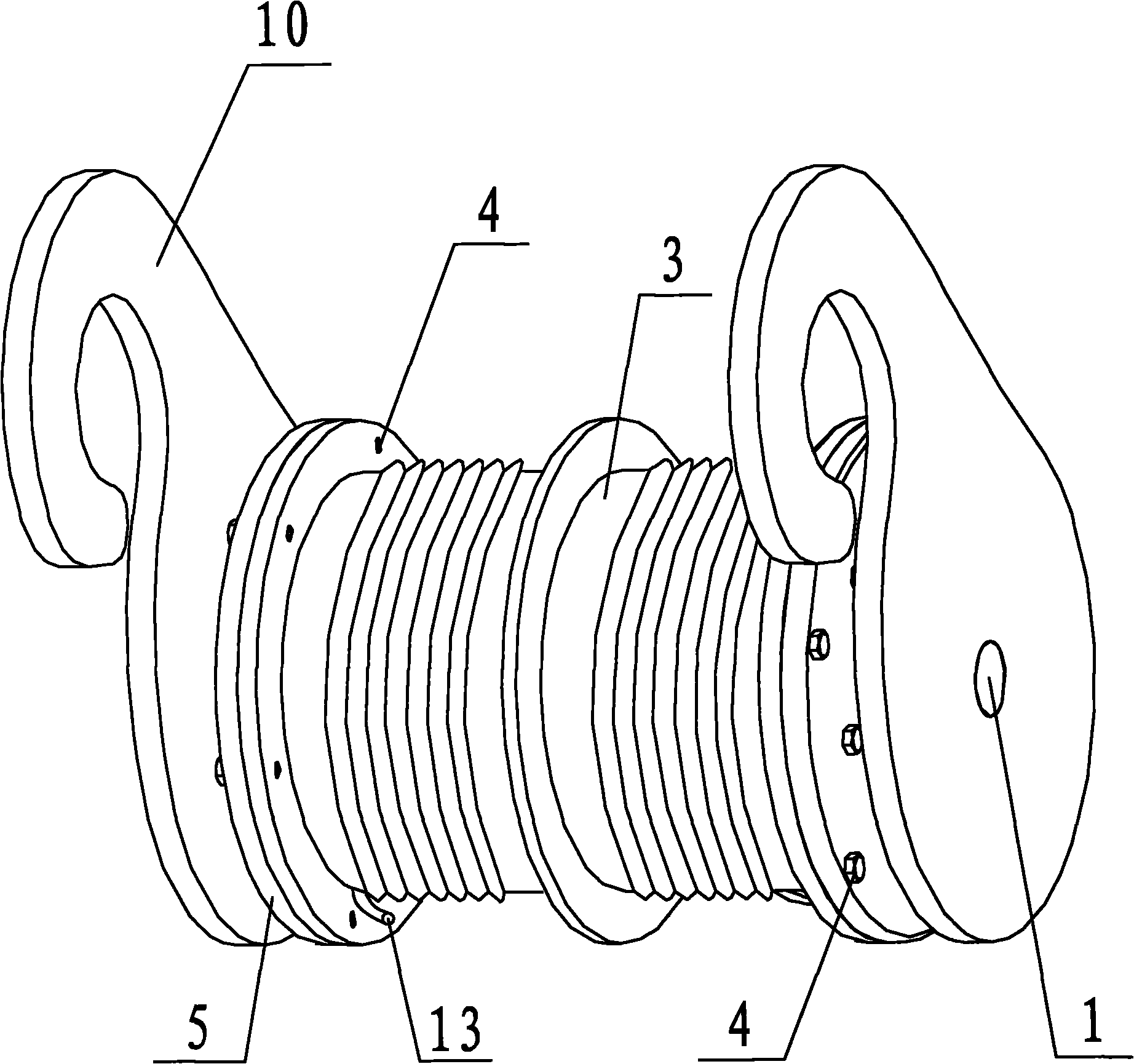

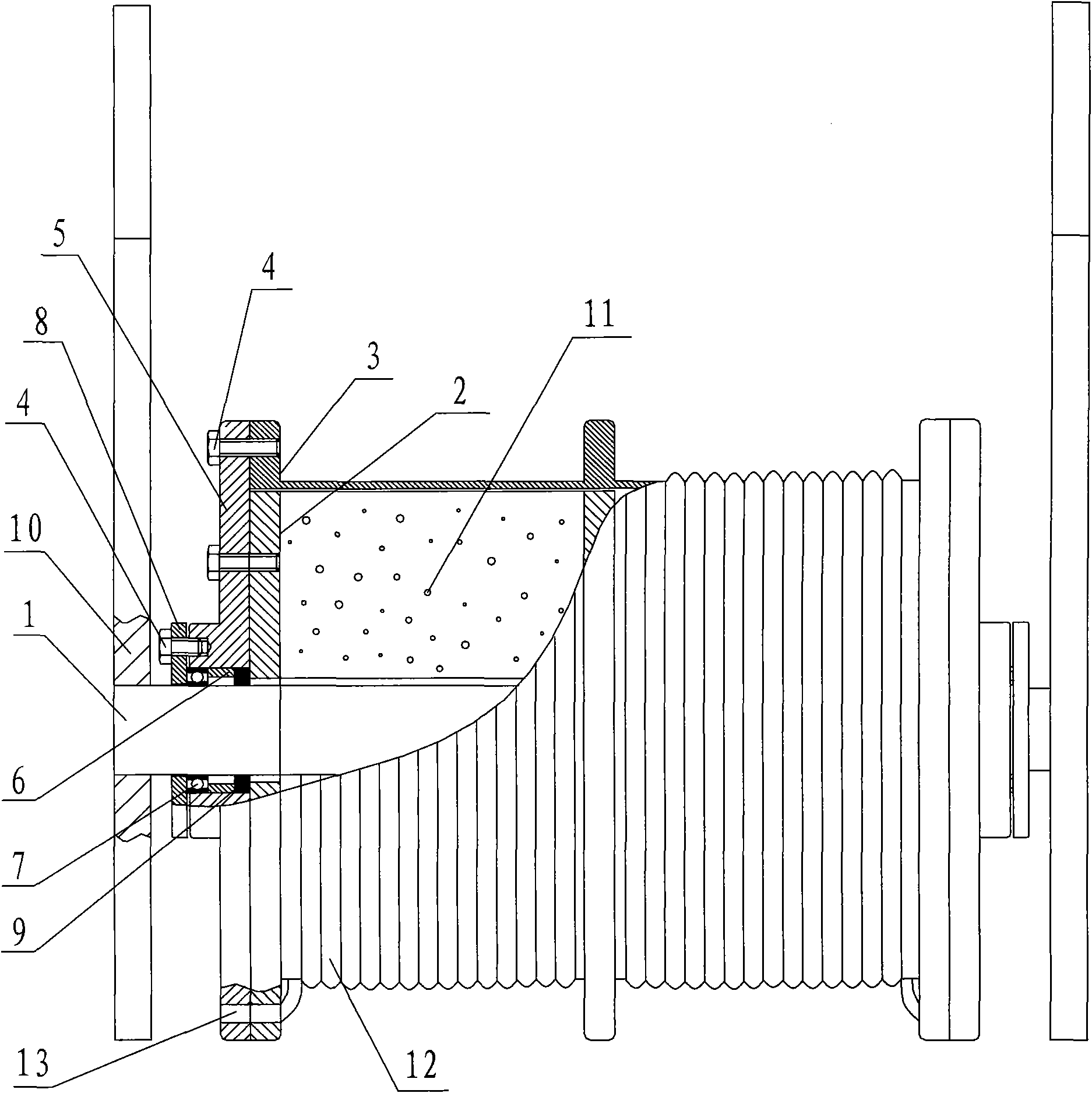

[0035] Such as figure 1 and figure 2 As shown, the present invention includes a rotary shaft 1, a damping rotor 2 sleeved on the rotary shaft 1 and a bobbin 3 sleeved on the damping rotor 2, both ends of the damping rotor 2 and the bobbin 3 are The bolt 4 is fixedly connected with the cover plate 5, the wire rope 12 used for escape is wound on the bobbin 3, and the two ends of the bobbin 3 and the corresponding positions on the cover plate 5 are provided with wire ropes for tying. 12 winding holes 13, the cover plate 5 is set on the rotary shaft 1 through the bushing 6 and the rolling bearing 7 accommodated in the bushing 6, the cover plate 5 is fixedly connected with the end cover 8 through the bolt 4, and the The rotary shaft 1 is provided with a sealing ring 9 for sealing the rotary shaft 1, the bushing 6 and the damping rotor 2, the two ends of the rotary shaft 1 are fixedly connected with hooks 10, the rotary shaft 1, the damping rotor 2, the winding A viscous liquid 1...

Embodiment 2

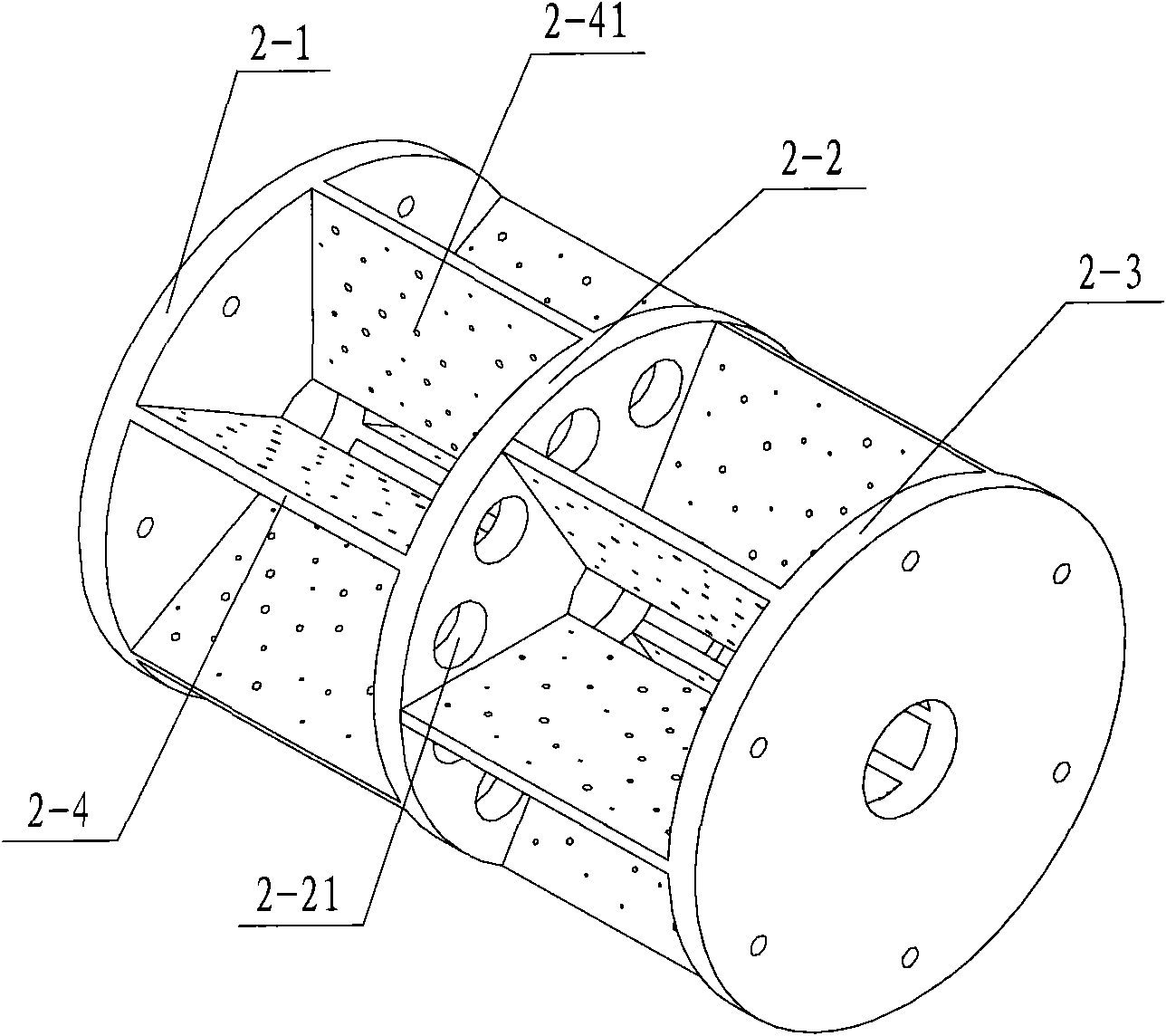

[0040] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the blade 2-4 is a helical blade, and the blade 2-4 connected between the annular end plate 2-1 and the middle partition plate 2-2 It is opposite to the spiral direction of the blade 2-4 connected between the middle partition plate 2-2 and the circular end plate 2-3; the through hole 2-21 is triangular. All the other structures are the same as in Example 1. Figure 4 Among them, the blade 2-4 connected between the annular end plate one 2-1 and the intermediate partition plate 2-2 and the blade connected between the intermediate partition plate 2-2 and the annular end plate two 2-3 The number of 2-4 is 6 pieces, and the unmarked circular holes on the annular end plate one 2-1 and the annular end plate two 2-3 are the holes that the bolt 4 needs.

[0041] The working principle and working process of the present invention are: when an emergency occurs, the escapee takes out the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com