Dynamic adjustment mechanism of bottom dead center of high-speed knuckle-joint press

A dynamic adjustment and press technology, which is applied in the field of presses, can solve the problems that the bottom dead center of the slider cannot be adjusted dynamically and affects the quality of stamping parts and the life of the mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

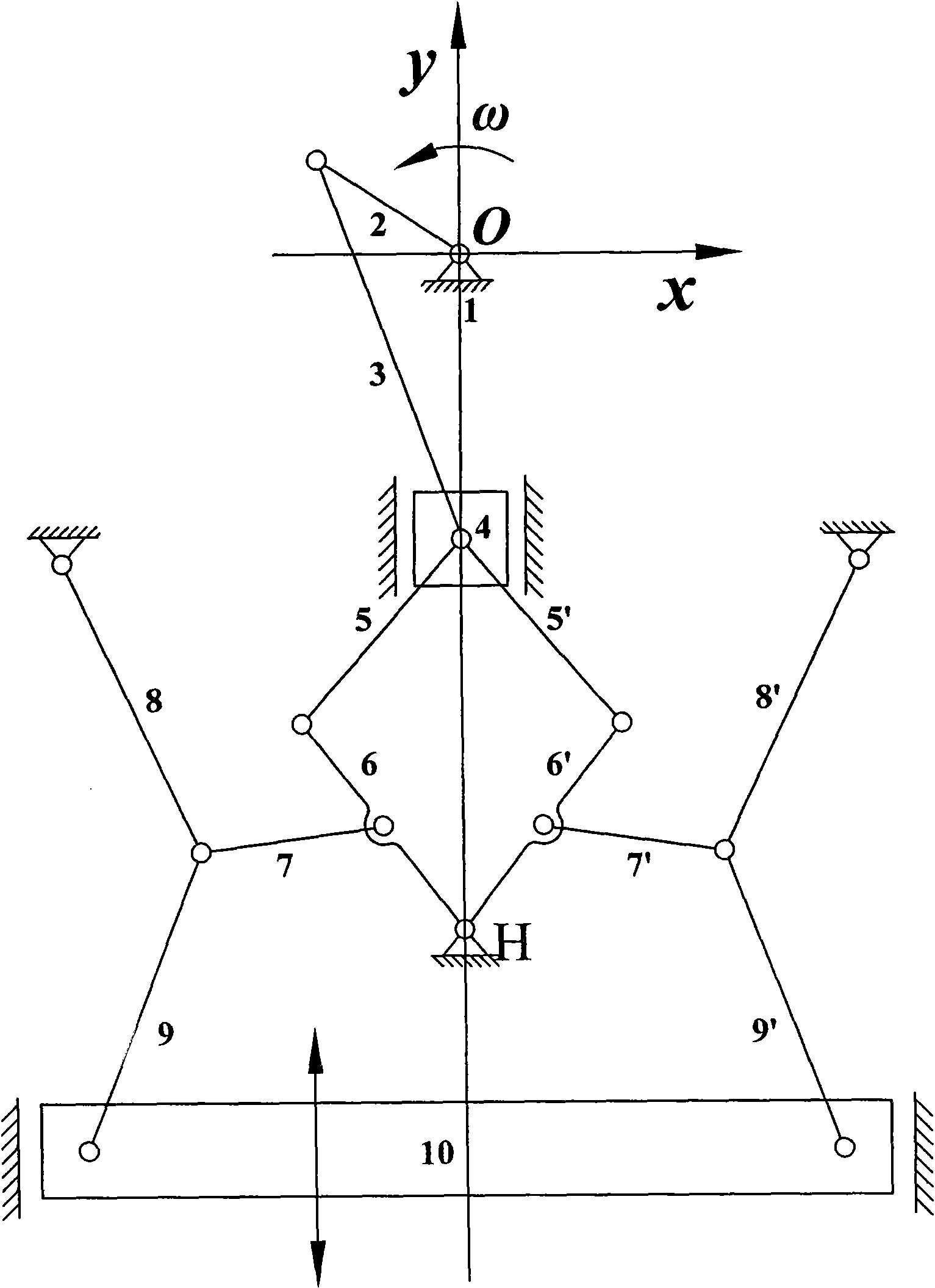

[0016] Such as figure 1 As shown: the crank 2 installed in the frame 1 drives the slider 4 to reciprocate up and down in the slideway through the connecting rod 3, and the slider 4, the swing rod 5, the swing rod 5', the support rod 6 and the support rod 6' form a rhombus Mechanism, support rod 6 and support rod 6 ' are hinged at H point. The connecting rod 7, the toggle rod 8, the ball joint rod 9 and the slider 10 constitute the toggle mechanism, the up and down reciprocating motion of the slider 4 drives the swing of the support rod 6, the connecting rod 7 is hinged on the swing rod 5, and pushes the toggle mechanism, The up and down reciprocating motion of the slider 10 is realized. When the position of the H point changes, the bottom dead center of the slider will change. In the present invention, the fixed fulcrum H is designed to be adjustable up and down, so as to realize the above functions.

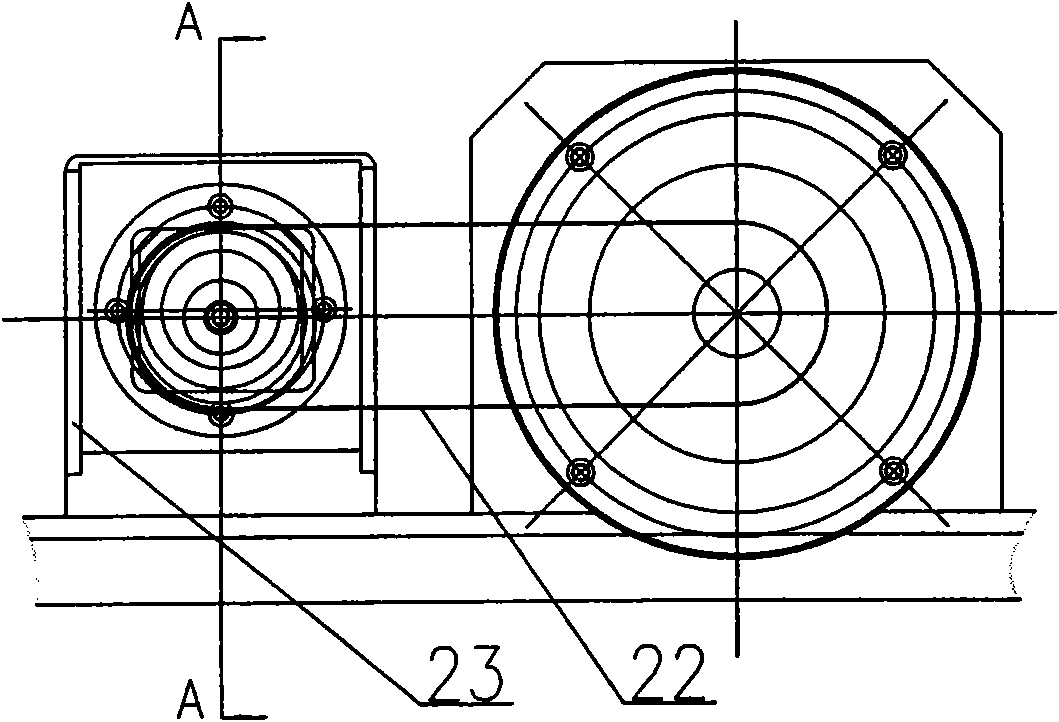

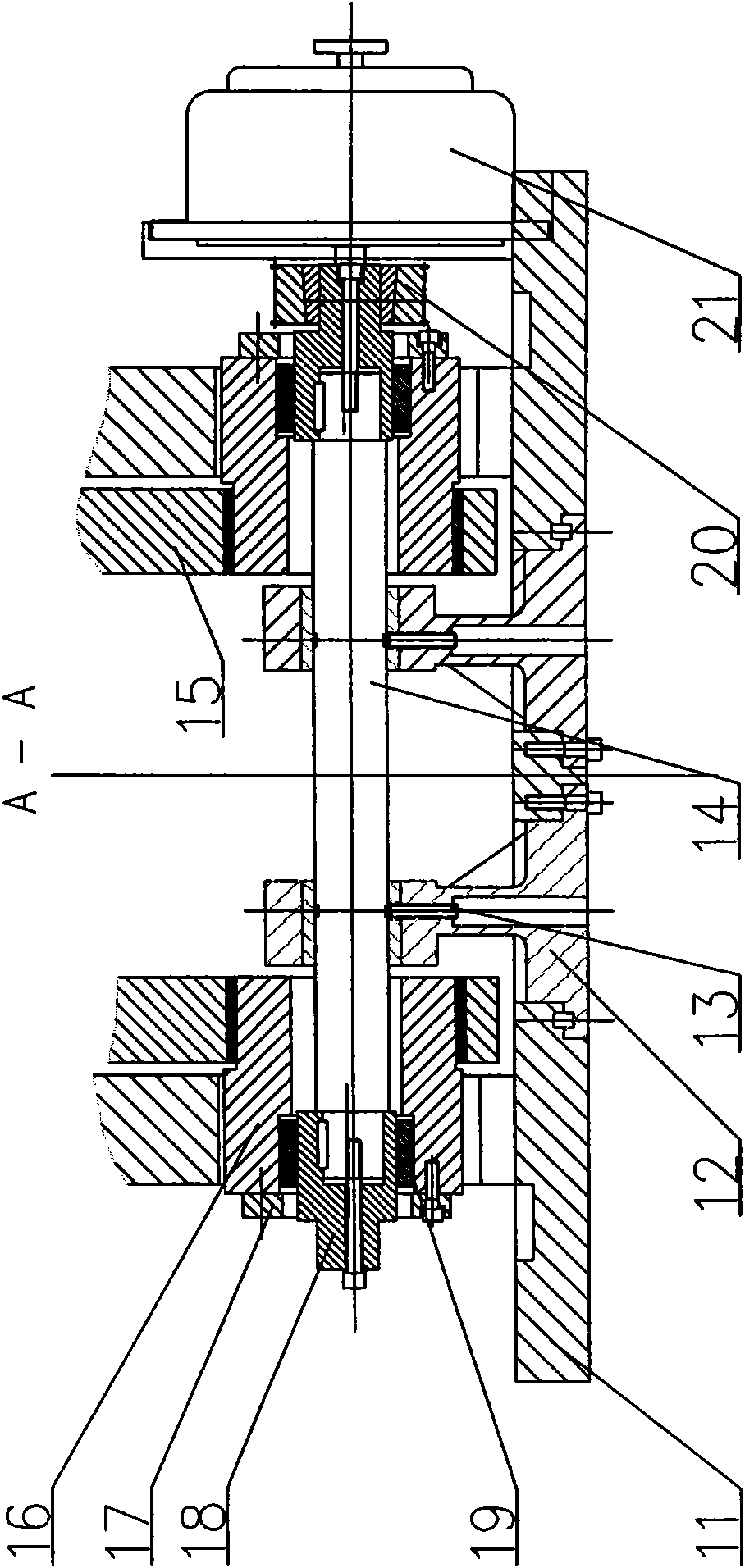

[0017] exist image 3 Among them, the two brackets 12 are fixed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com