Angle-adjustable printing screen and angular adjusting device thereof

An angle adjustment device, a technology for printing screen, applied in printing, printing machine, rotary printing machine and other directions, can solve the problems of low precision, difficult to meet requirements, etc., and achieve the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

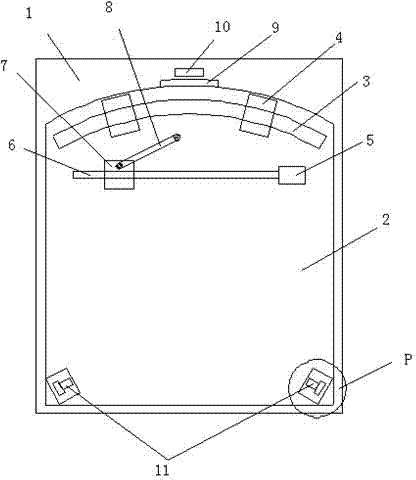

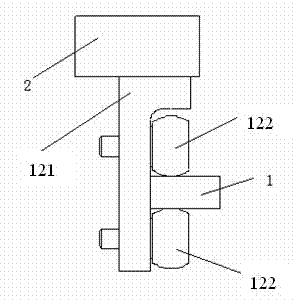

[0024] Install a section of arc guide rail on the edge of the part that needs to make angular movement, and then use a connecting rod to drive a point close to the moving part of the arc guide rail, so that the moving part can make angular movement around the center of the arc guide rail along the arc guide rail. We call this driving method the edge driving method.

[0025] If the center drive method is adopted (that is, the force application point of the drive motor is set at the center of the rotating part), usually the center rotating motor has 10,000 pulses per revolution, and there is an error of about 1 pulse per revolution on average, then the resulting angle error For: 1 / 10000=3.6*10 -2 Spend. In this embodiment, we use the same printing screen and rotary table, the radius of the arc guide rail used is 300mm, and the minimum reading of the grating scale used is 1 μm, then the angular error generated at this time is: (1 / 2*3.14 *300*103)*360=1.9*10 -4 Compared with...

Embodiment 2

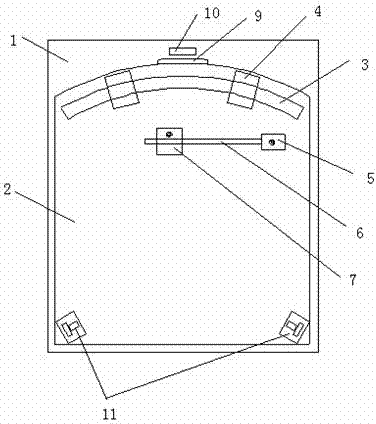

[0031] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the transmission mechanism does not include the drive link 8 in Embodiment 1, but only consists of a lead screw 6 and a lead screw nut 7 thereof, and the lead screw nut 7 can be Change its position on the described leading screw 6 along with the rotation of leading screw 6, and the two ends of described leading screw 6 are connected with described motor 5 and wire mesh frame 2 in rotatable manner respectively, and described motor 5 can It is connected to the base 1 in a rotating manner. When the lead screw 6 rotates under the drive of the motor 5, the transmission mechanism composed of the lead screw 6 and its lead screw nut 7 drives the wire mesh frame 2 to rotate along the track of the arc track, and the motor 5 also surrounds it on the base 1 A fixed point rotation on . Since the screw nut 7 is running in a straight line, the angle of the screw 6 will change at any time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com