Buckling-restrained brace member consisting of four bound angle steels

A technology of anti-buckling support and four angle steels, which is applied in the direction of building components, earthquake resistance, etc., can solve the problems that it is difficult to ensure that the reserved gap between the core component and the peripheral constraint components meets the accuracy, poor durability, and single variety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

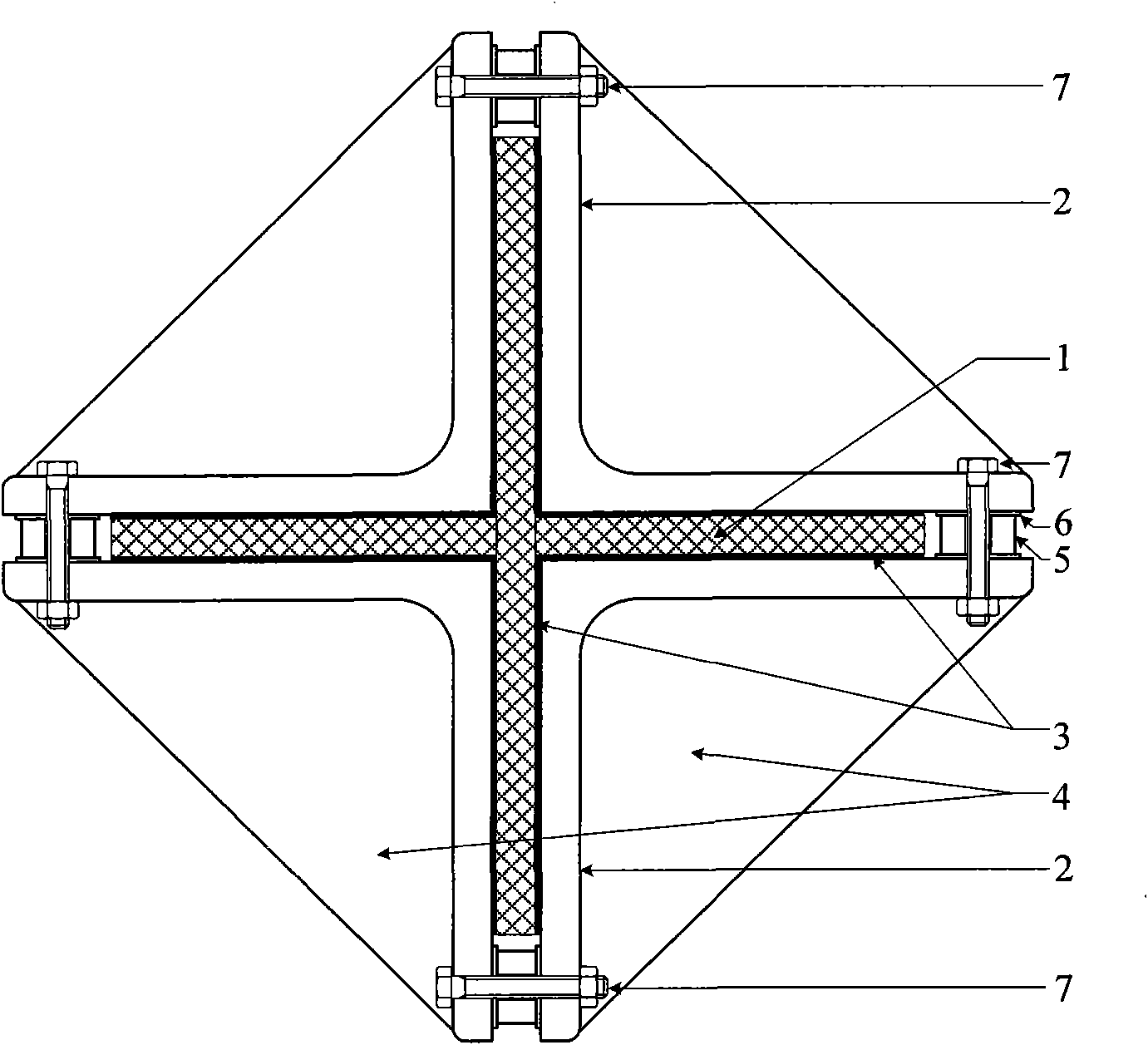

[0023] Attached below Figure 1~5 , detailing the implementation of this patent.

[0024] Such as figure 1 As shown, a buckling-resistant bracing member consisting of four angle steel bundles includes the following components:

[0025] 1——cruciform inner core member;

[0026] 2——Equilateral angle steel, four pieces;

[0027] 3 - hard rubber;

[0028] 4 - Stiffener;

[0029] 5——steel backing plate;

[0030] 6——Rubber gasket;

[0031] 7——High-strength bolts;

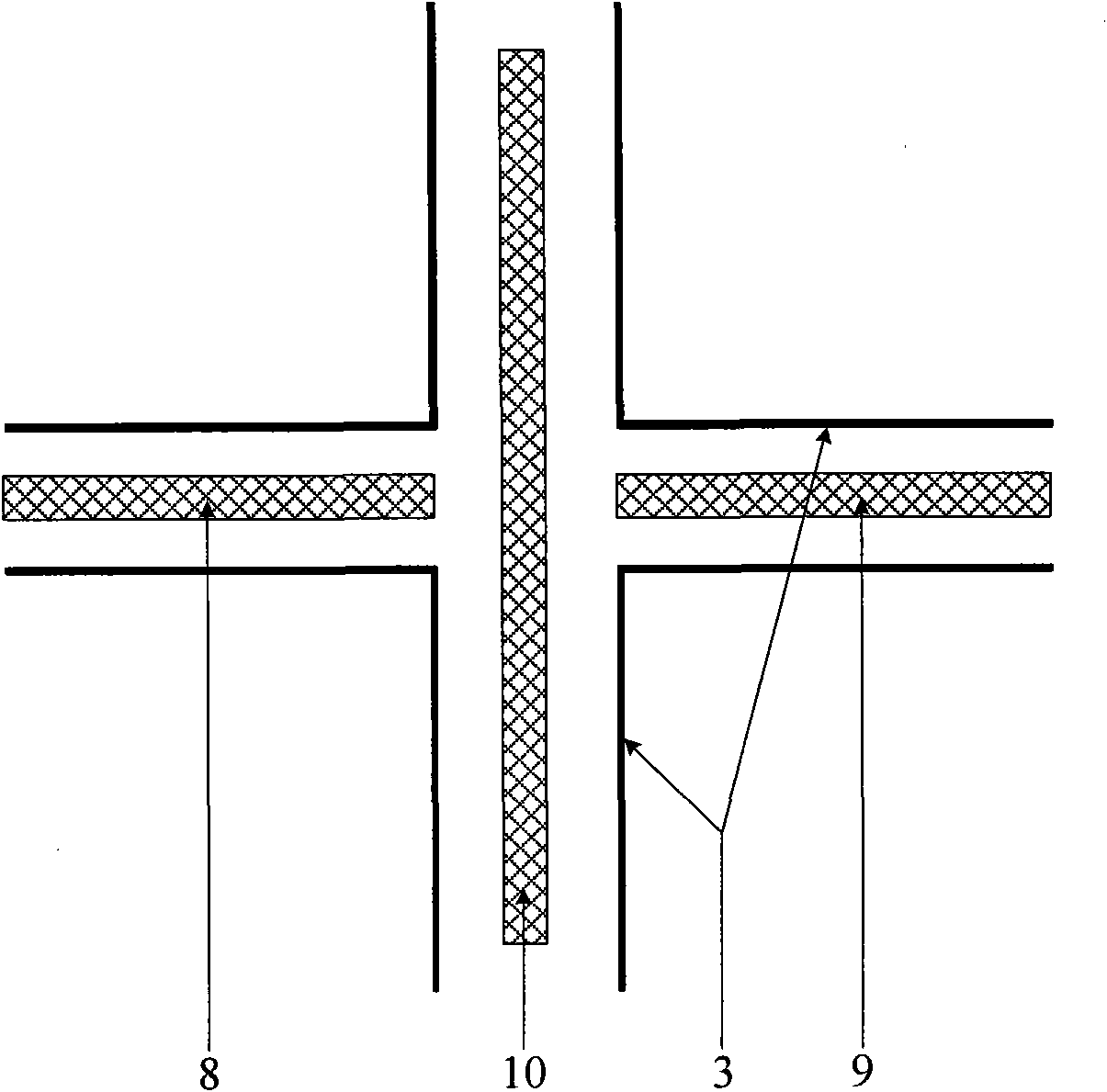

[0032] Such as figure 2 As shown, the cross-shaped core member (1) is composed of two narrower flat steel plates (8), (9) and a wider flat steel plate (10) through welding; as figure 2 , 5 As shown, hard rubber (3) is pasted on the surface of the area wrapped by four angle steels of the cross-shaped core member (1);

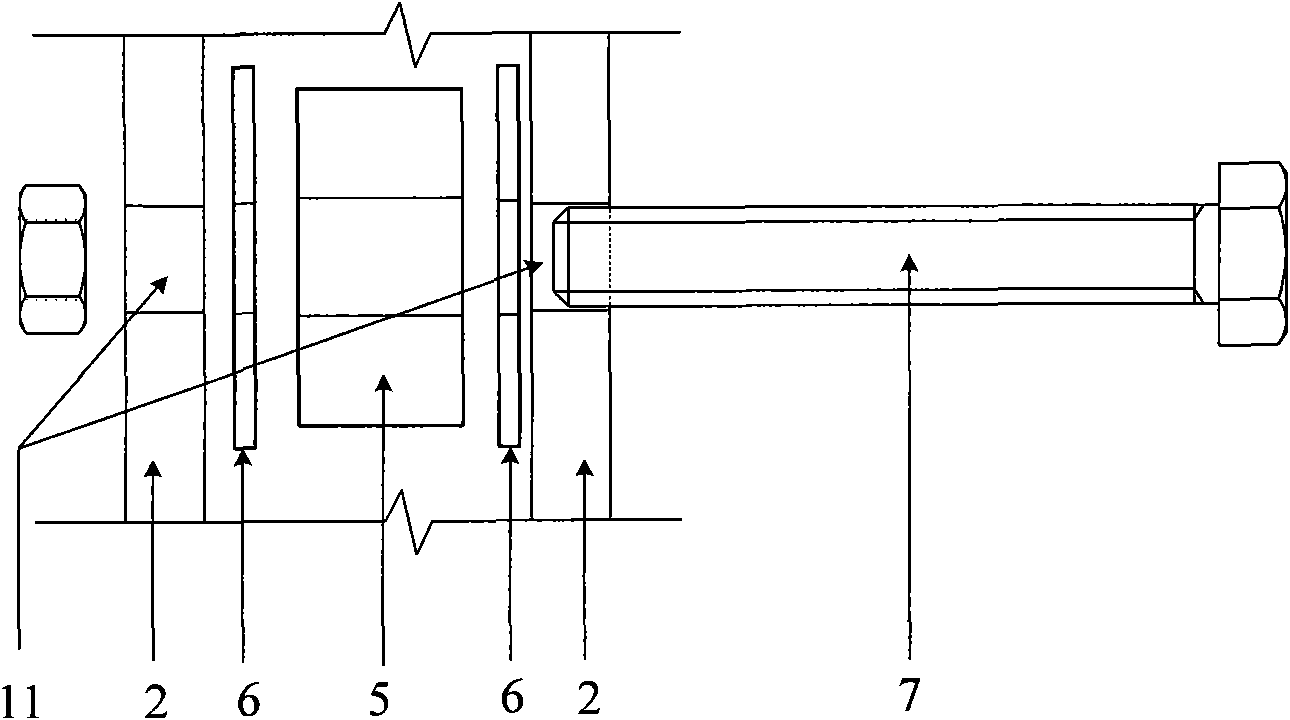

[0033] Such as figure 1 , 4 , shown in 5, there are totally four equilateral angle steels (2), and its size is all the same, and its side length is greater than the side length of the inner cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com