Frequency-modulation mass anti-flection support

An anti-buckling bracing and anti-buckling technology, applied in the direction of anti-vibration, building components, etc., can solve the problems of vibration reduction requirements, inability to reduce inertial force and structural vibration, and inability to reduce wind load structural vibration, etc., to achieve the effect of improving functionality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

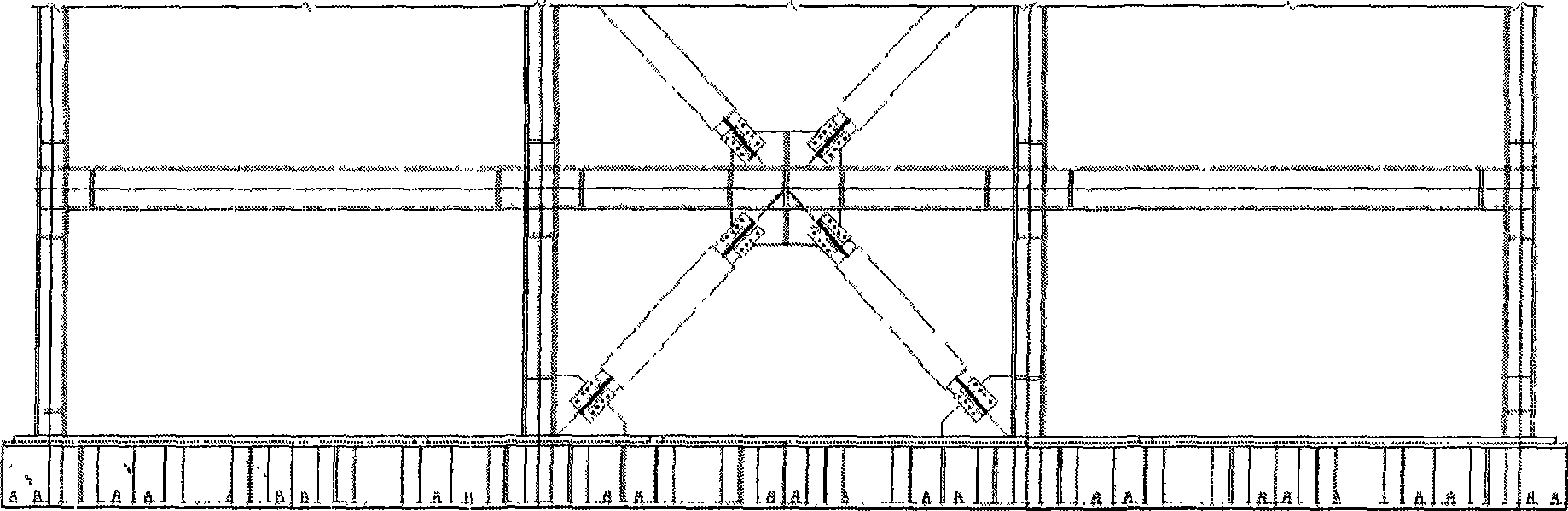

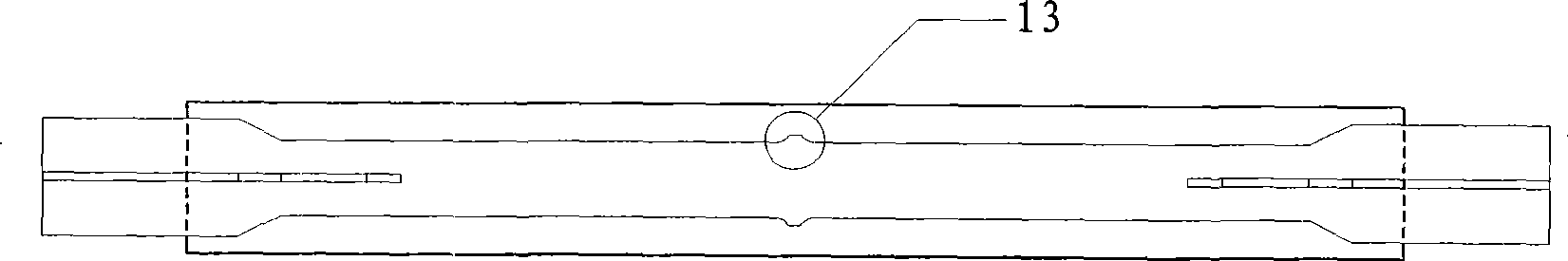

[0040] Example 1: Fabrication of FM mass anti-buckling support for bolted connections

[0041] Preparation of main components: According to the requirements of structural design on yield bearing capacity and elastic stiffness, the material, section and length of working section of steel core 6 are firstly selected, and the working section, transition section and connecting end of steel core 6 are machined according to design. Determine the jacket steel pipe 7 according to the length of the steel core 6 working section, and determine its thickness according to the construction requirements, and drill holes at the ends of the jacket steel pipe 7. According to the length of the working section of the steel core 6, silica gel and polytetrafluoroethylene are selected as the damping material 8, painted and pasted on the surface of the steel core 6. According to the requirements of structural design on the natural vibration frequency of the distributed TMD, design the resilient eleme...

Embodiment 2

[0044] Example 2: Fabrication of anti-buckling support for welded-anchor connection frequency modulation quality

[0045] The preparation of main element: with embodiment 1.

[0046] Assembly and installation: install anchor bolts 5 in the holes at the ends of the jacket steel pipe 7 . The steel core 6 is penetrated into the outer jacket steel pipe 7 and temporarily fixed. C30 gravel concrete is poured vertically and cured to the design strength. The gusset plate 1 is welded and installed near the lower node of the main structure. Hoist the FM mass anti-buckling support in place for temporary fixation, use a torque wrench to tighten the bolts of the fixed node connectors 2 and 3, and assemble the rebound element 4 at the same time. Connect the upper gusset plate of the main structure with the anti-buckling support of frequency modulation quality, and weld the upper gusset plate 1 to the upper frame node after it is in place. Remove the temporary fixation between the outer ...

Embodiment 3

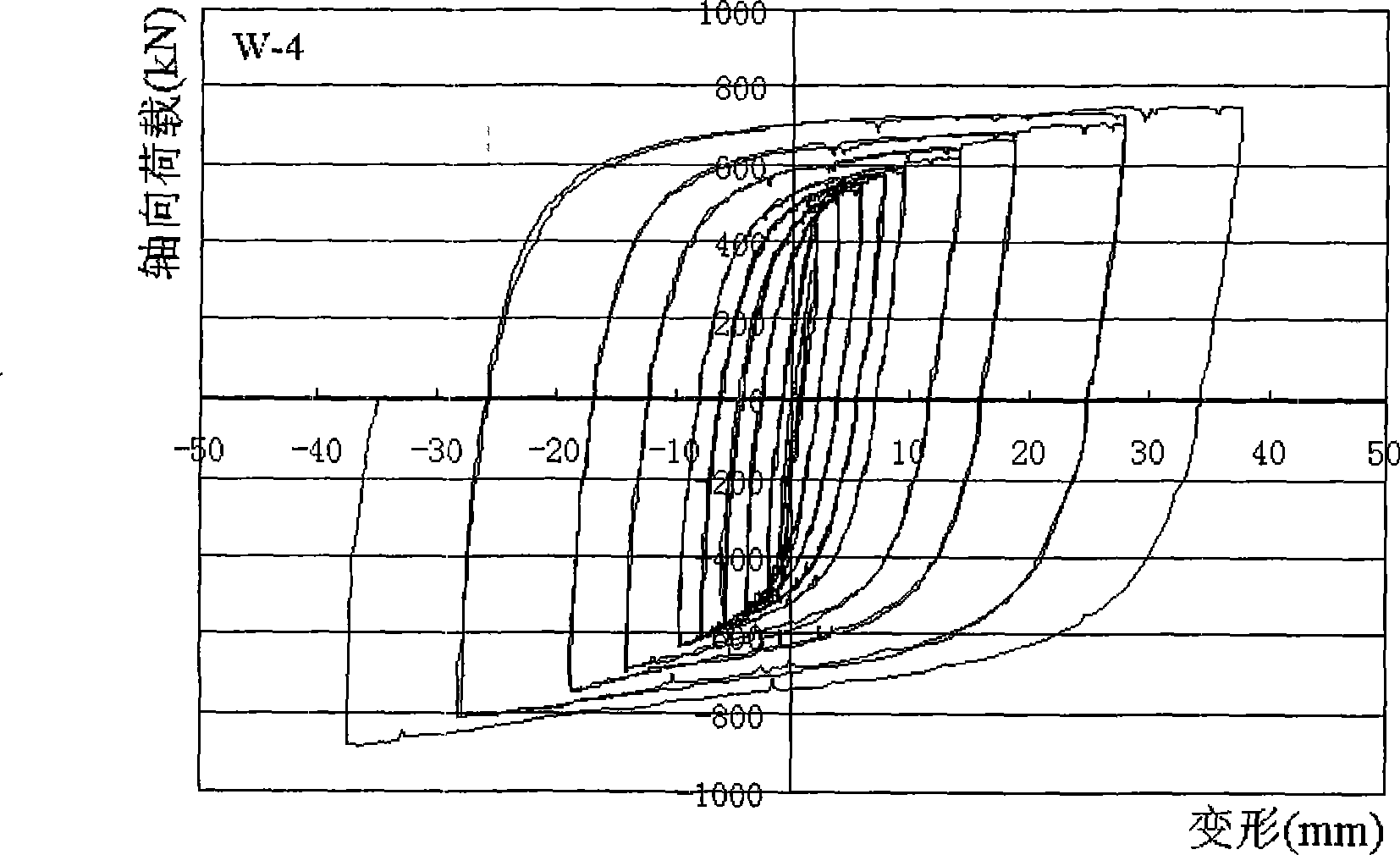

[0048] Example 3: Calculation example and effect comparison of microseismic reduction design

[0049] The present invention designs two 4-story double-span (plane) frame structure calculation examples. The structural components in the two structural calculation examples are the same, but the damping (vibration) schemes are different, see Table 1. Among them, the S4B2-0 model adopts the common anti-buckling support, which aims to achieve the purpose of energy dissipation and shock absorption under the rare intensity; Vibration) to reduce structural vibration, energy dissipation and shock absorption under strong earthquakes. This example is mainly used to compare that the present invention has a certain effect on reducing mechanical vibration under the action of frequent earthquakes that are difficult to control, while the effect of energy dissipation and shock absorption under rare intensity remains unchanged.

[0050] The specific design parameters of the two structures are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com