Submarine pipeline bending-resisting fixer and installing method thereof

A technology for submarine pipelines and fixtures, applied in the direction of pipeline damage/wear prevention, pipeline support, pipeline protection, etc., can solve the problems of large vertical uplift or lateral displacement, single form and function of buckling devices, etc., to achieve convenient operation, The effect of reducing construction costs and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

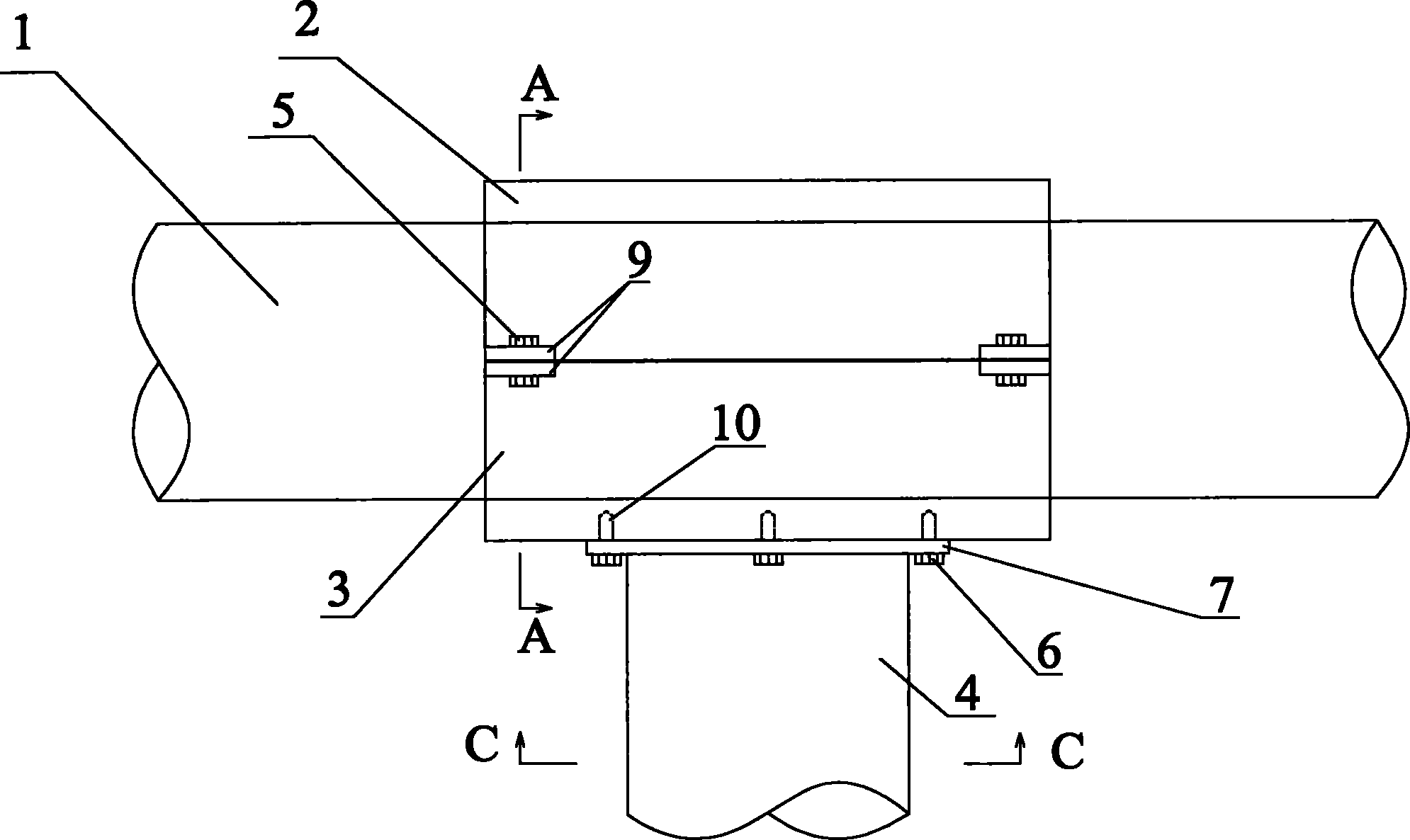

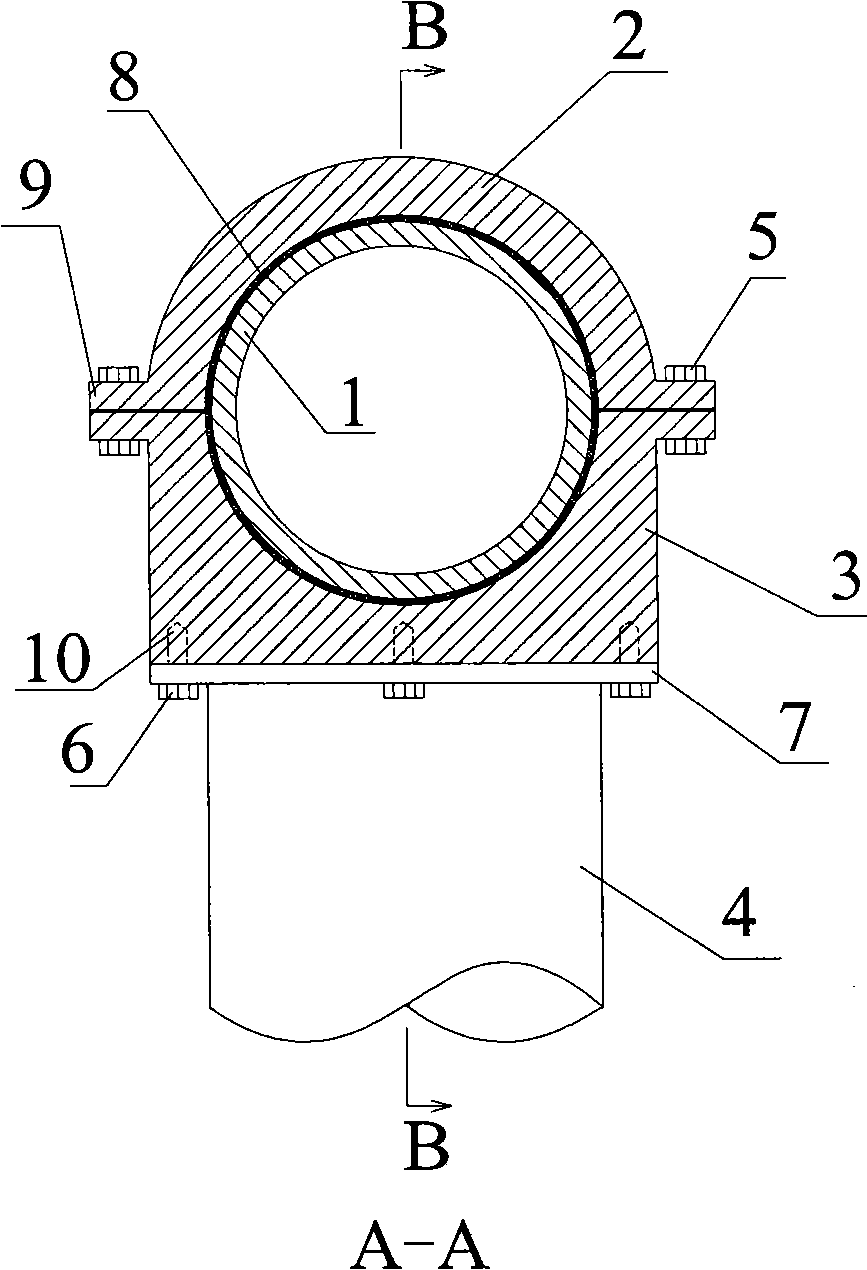

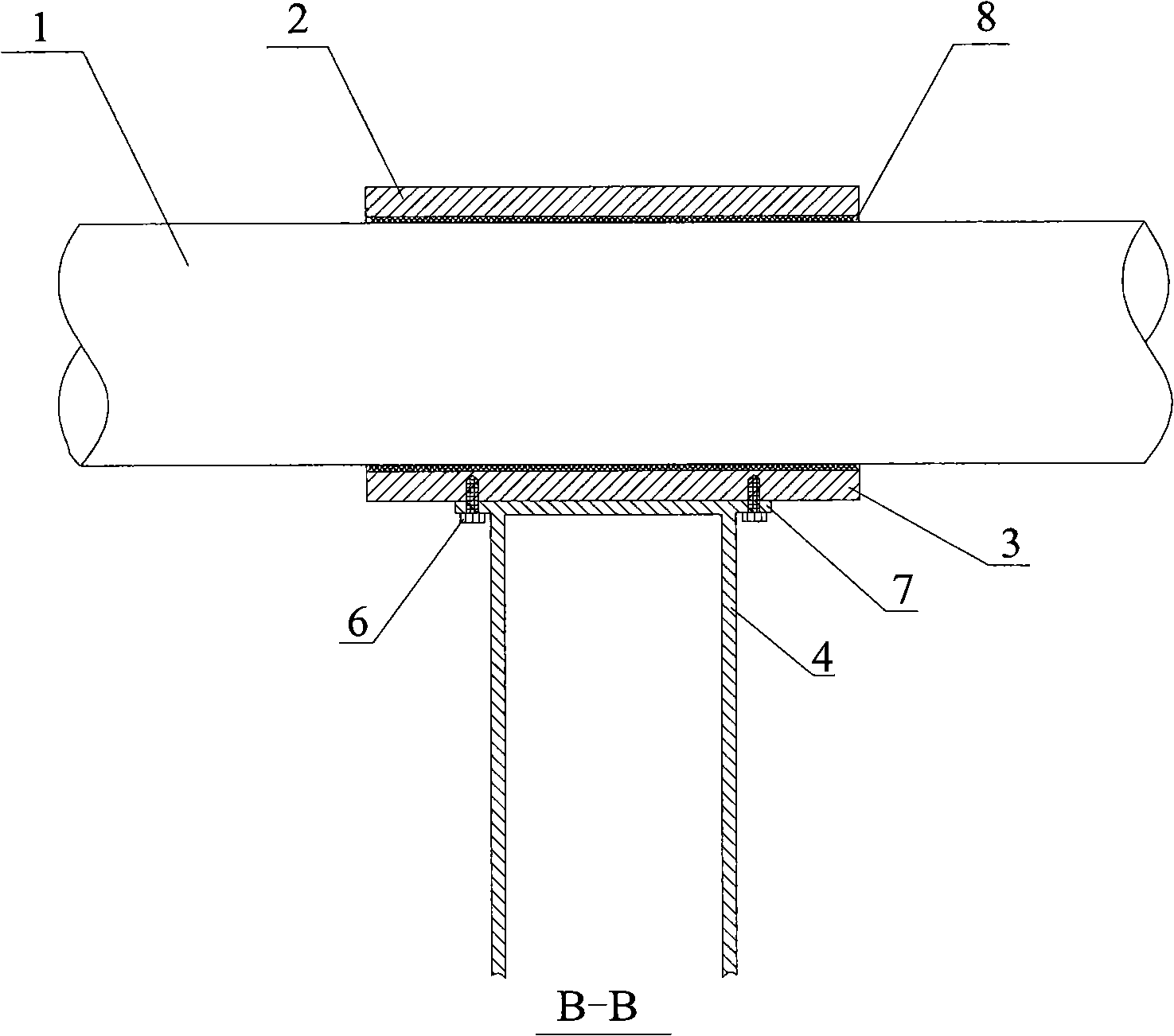

[0016] Front view of a section of subsea pipeline fitted with buckling anchors, such as figure 1 shown. The anti-bending fixture of the submarine pipeline involved in the present invention is clamped and fixed on the rubber layer 8 on the outer surface of the pipeline by the upper shell 2, the lower base 3 and the barrel structure 4 through bolt connection. The upper shell 2 is semi-circular, the lower base 3 is a cuboid with a semi-cylindrical hollow, and the bolt and nut pair 5 connects the upper shell 2 and the lower base 3 through the overhanging eye plate 9 . The bottom surface of the lower base 3 is drilled with a screw hole 10, and the bolt 6 passes through the top plate 7 of the barrel structure and is inserted into the screw hole 10, so that the lower base 3 and the barrel structure 4 are assembled together. The barrel-shaped stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com