Grate distributing hopper with automatic swiping device

An automatic cleaning and grate technology, applied in the field of metallurgical sintering pellets, can solve the problems of inconvenient manual cleaning, sticky material on the receiving surface, poor environment, etc., and achieve the effects of easy installation and positioning, simple structure and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

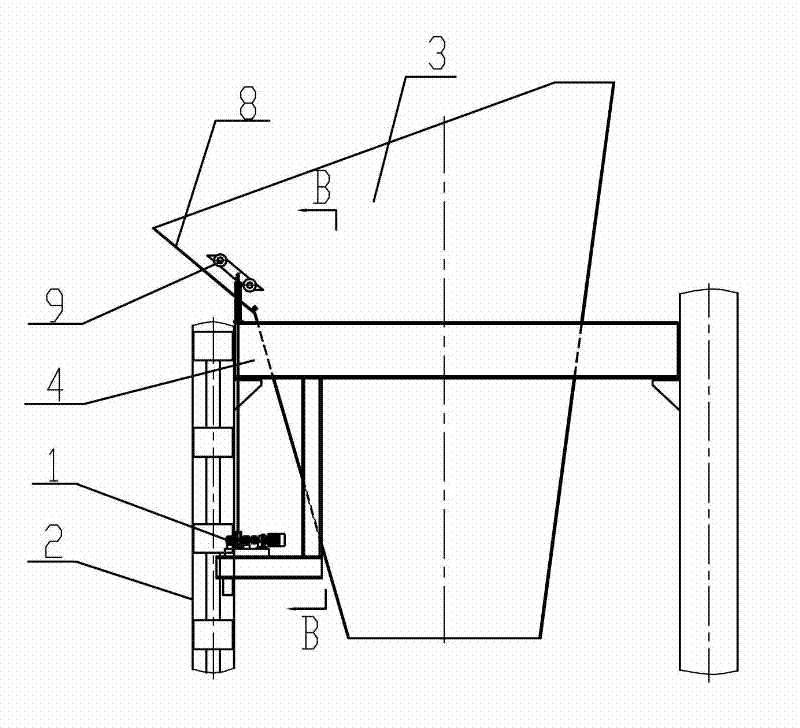

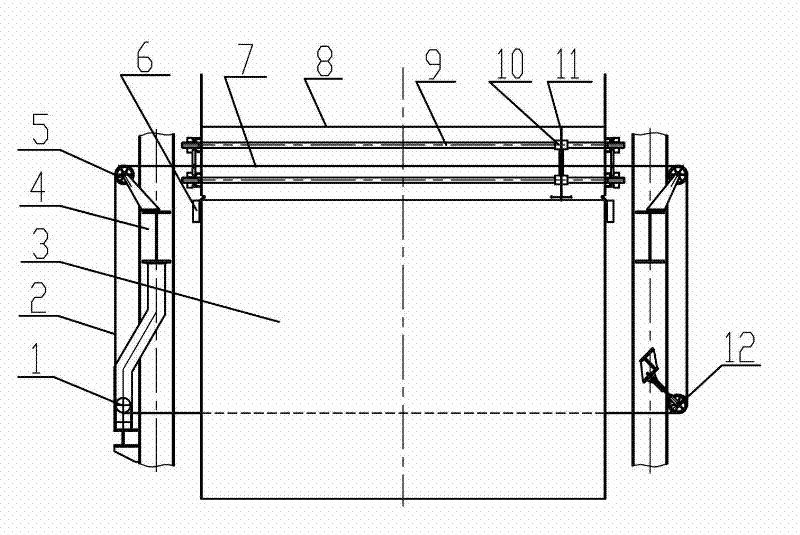

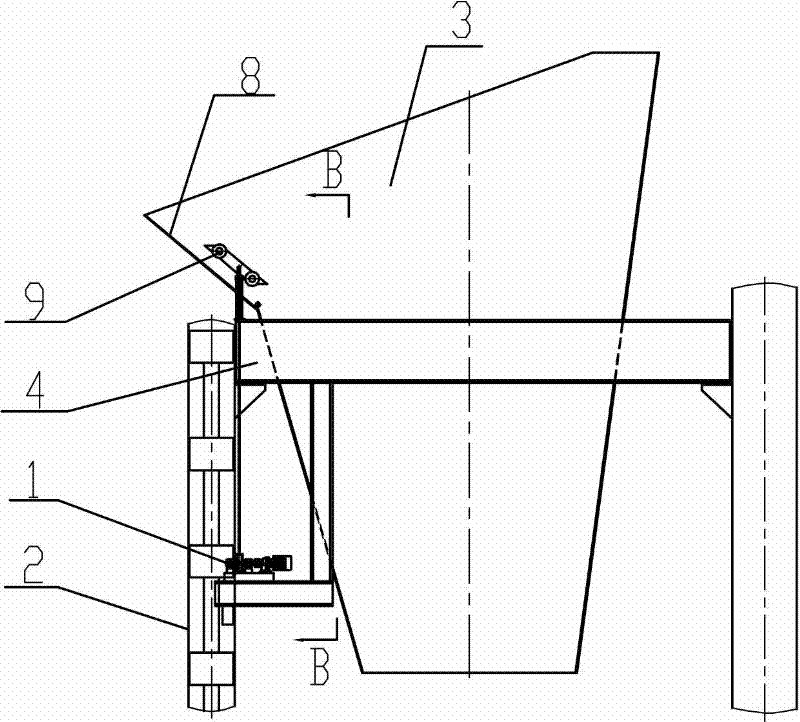

[0015] Such as figure 1 , figure 2 Shown, the grate machine bulk hopper with automatic cleaning device of the present invention comprises bulk hopper body 3, is characterized in that is provided with automatic cleaning device on described bulk hopper body, and described automatic cleaning device is arranged on Both sides of the bulk hopper body 3 are respectively the crossbeam 4 connected to the grate frame, the transmission mechanism connected to the grate frame 2, and the scraper connected to the two side plates of the bulk hopper body 3. The plate mechanism is composed of proximity switches 6 below the scraper mechanism on both sides of the bulk hopper body 3, and the proximity switches 6 are connected to the electric control device.

[0016] Described transmission mechanism is by the winch 1 that is connected with chain grat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com