Anti-falling apparatus for socket

An anti-dropping and socket technology, which is applied in the direction of coupling devices, parts of connecting devices, electrical components, etc., can solve problems such as poor scalability, disassembly and installation of threaded fragile rings, and poor anti-off capabilities, so as to achieve safe and firm assembly connections. Good scalability and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

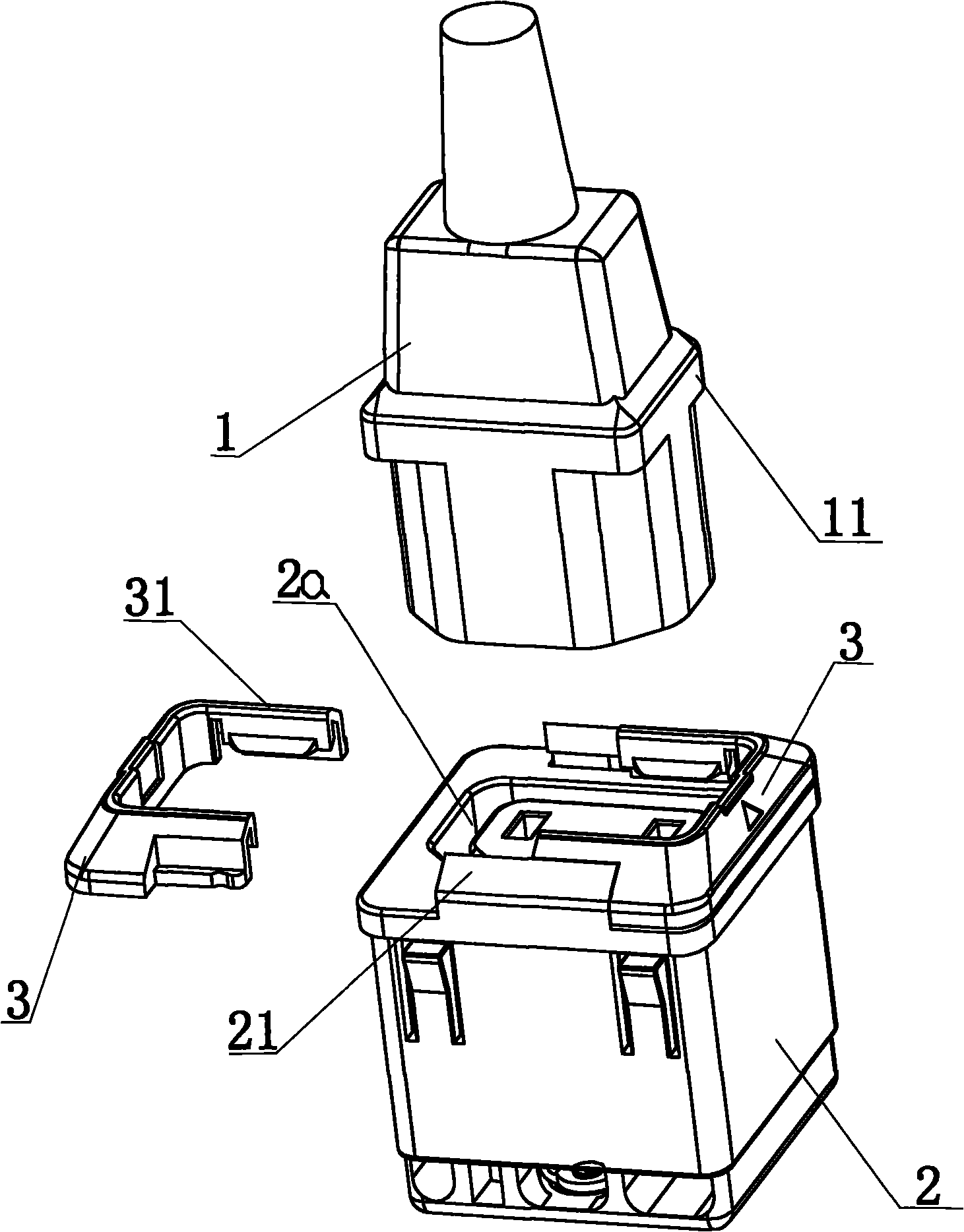

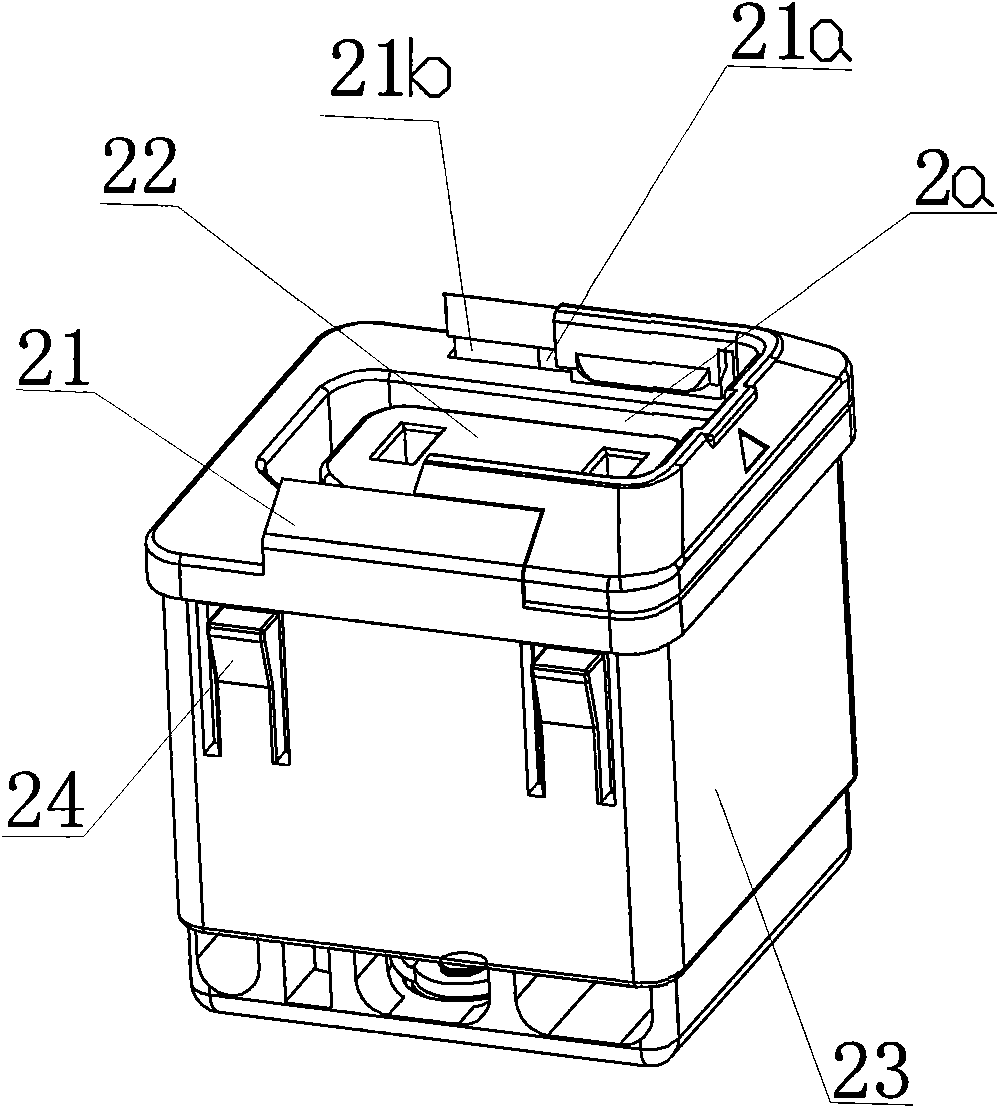

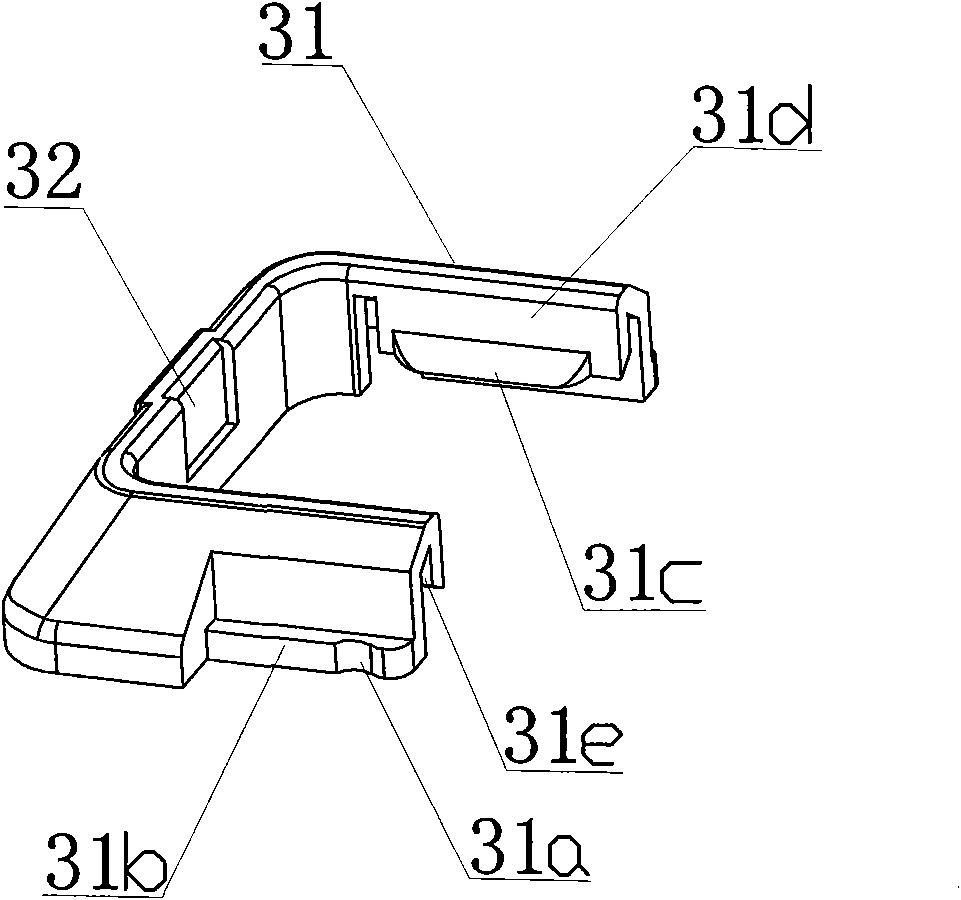

[0027] Such as Figure 1 to Figure 7 As shown, the socket anti-dropping device of the present invention includes a socket 2 that is mated with a plug 1 socket, wherein: the outer sides of the two opposite edges of the socket 2 connection port 2a are all provided with sliding covers extending upward and inward. Positioning clamp 21, and the inner side of positioning clamp 21 is shaped on the anti-falling fixing convex buckle 21a; the end edge of the other two opposite sides of the connection port 2a has at least one end edge equipped with socket anti-falling buckle 3, and the socket is anti-falling The buckle 3 is formed with a lever member 31 that is slidably embedded in the positioning clamps 21 on both sides, and the outer sides of the lever member 31 on both sides are all formed with an anti-falling-off fixing buckle locked with the anti-falling-off fixing convex buckle 21a Groove 31a, and the inner side of at least one side of the lever member 31 is formed with an elastic ...

Embodiment 2

[0032]In this embodiment, the socket 2 includes an inner socket 22 and a socket shell module 23 that can be electrically connected and fitted independently with the plug 1 , and the inner socket 22 is fixedly fitted in the socket shell module 23 . Adopting socket housing module 23 to cooperate with inner socket 22 expands the fitting space of inner socket 22, and both sides corresponding to socket housing module 23 are all shaped with embedded fixed elastic buckle 24 that is connected with the external connecting body, so that socket housing module 23 It can be easily matched with the electric board or frame, and the inner socket 22 is assembled in the socket shell module 23, which can not only protect the inner socket 22 from being damaged, but also change the installation mode of the inner socket 22 and the external electric board or frame. Be concise and easy. Socket shell module 23 and inner socket 22 are matched to form socket 2 as a whole, and the outer sides of the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com