Dissolving apparatus

A dissolving device and solution technology, applied in the direction of dissolution, dissolution, transportation and packaging, etc., can solve the problem of inability to dissolve gas into liquid, and achieve the effect of increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

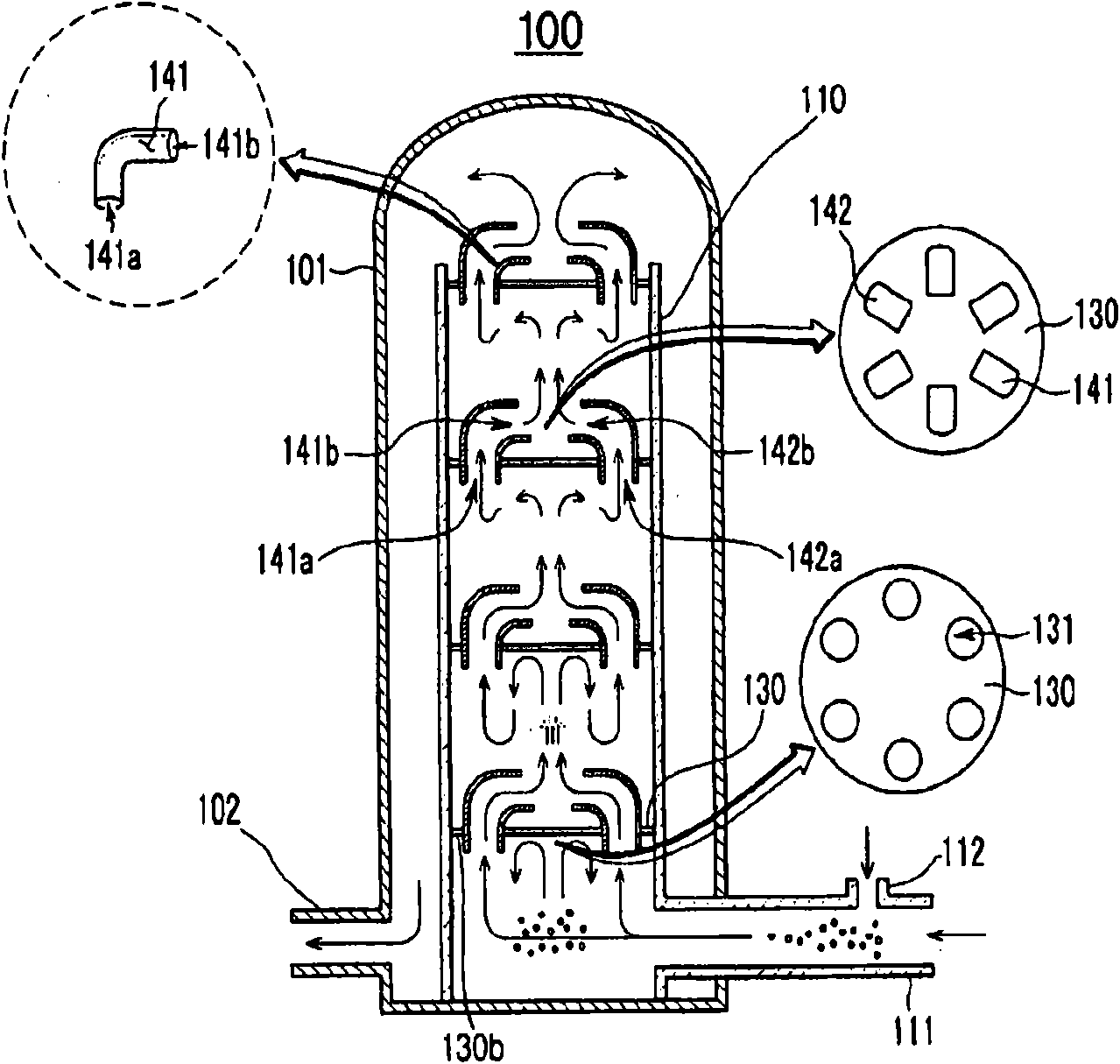

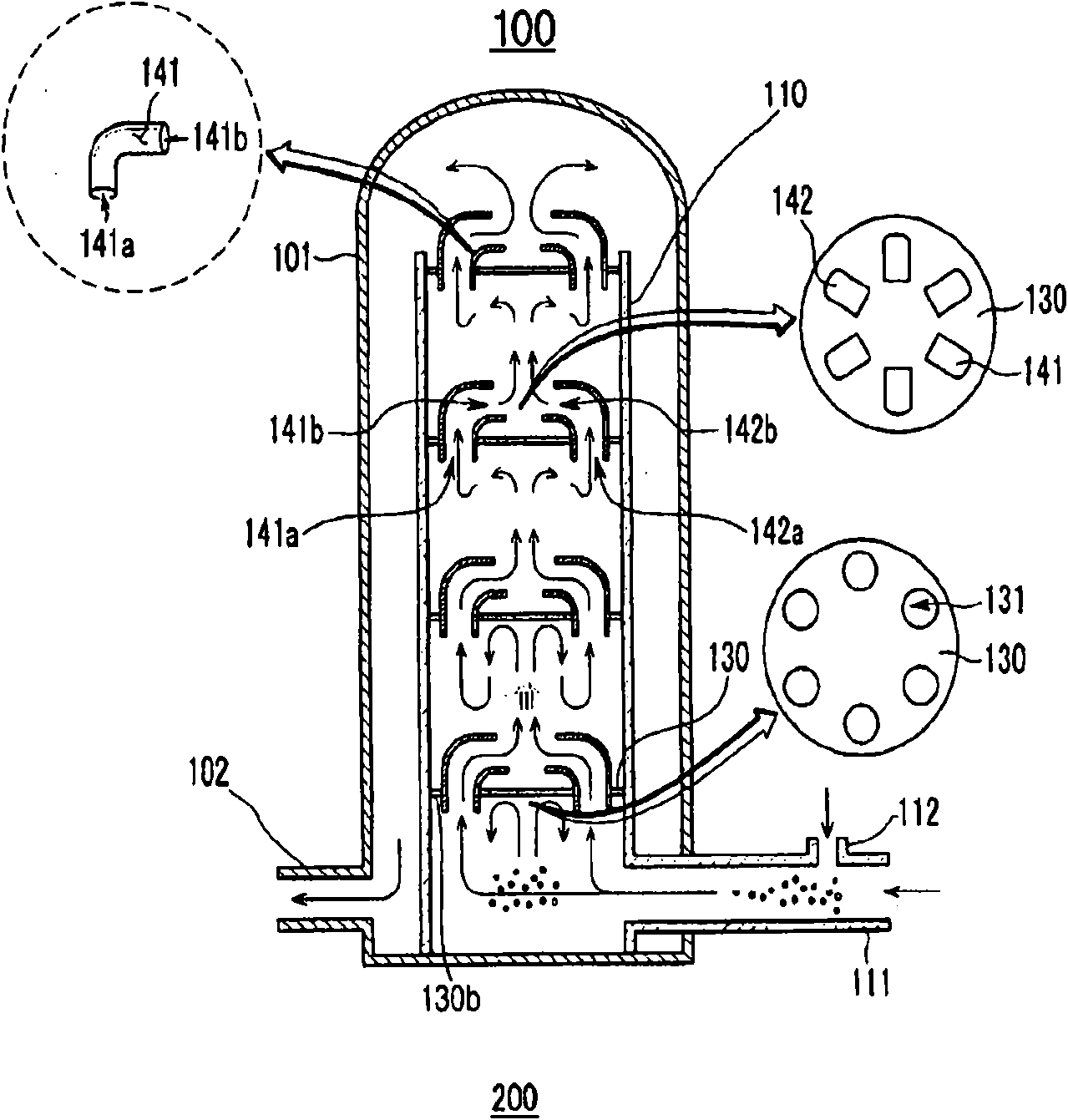

[0012] figure 1 is a cross-sectional view of the dissolving device 100 according to the first embodiment of the present invention, showing the circulation of the first fluid and the second fluid.

[0013] Such as figure 1 As shown, the dissolution device 100 according to the present invention includes a wear-resistant tank 101 , a first supply pipe 111 , a second supply pipe 112 , a vortex guide shell 110 , a plate 130 , and vortex guide pipes 141 and 142 . The dissolving device 100 forms a solution by dissolving the second fluid in the first fluid. The first fluid is a liquid, such as water, and the second fluid is a gas or liquid with properties different from those of the first fluid. In the following description, the first fluid is referred to as a first liquid, and the second fluid is referred to as a second liquid or gas for convenience.

[0014] The wear tank 101 surrounds the vortex guide shell 110 and has an outlet 102 for draining the solution on one side of the w...

no. 2 example

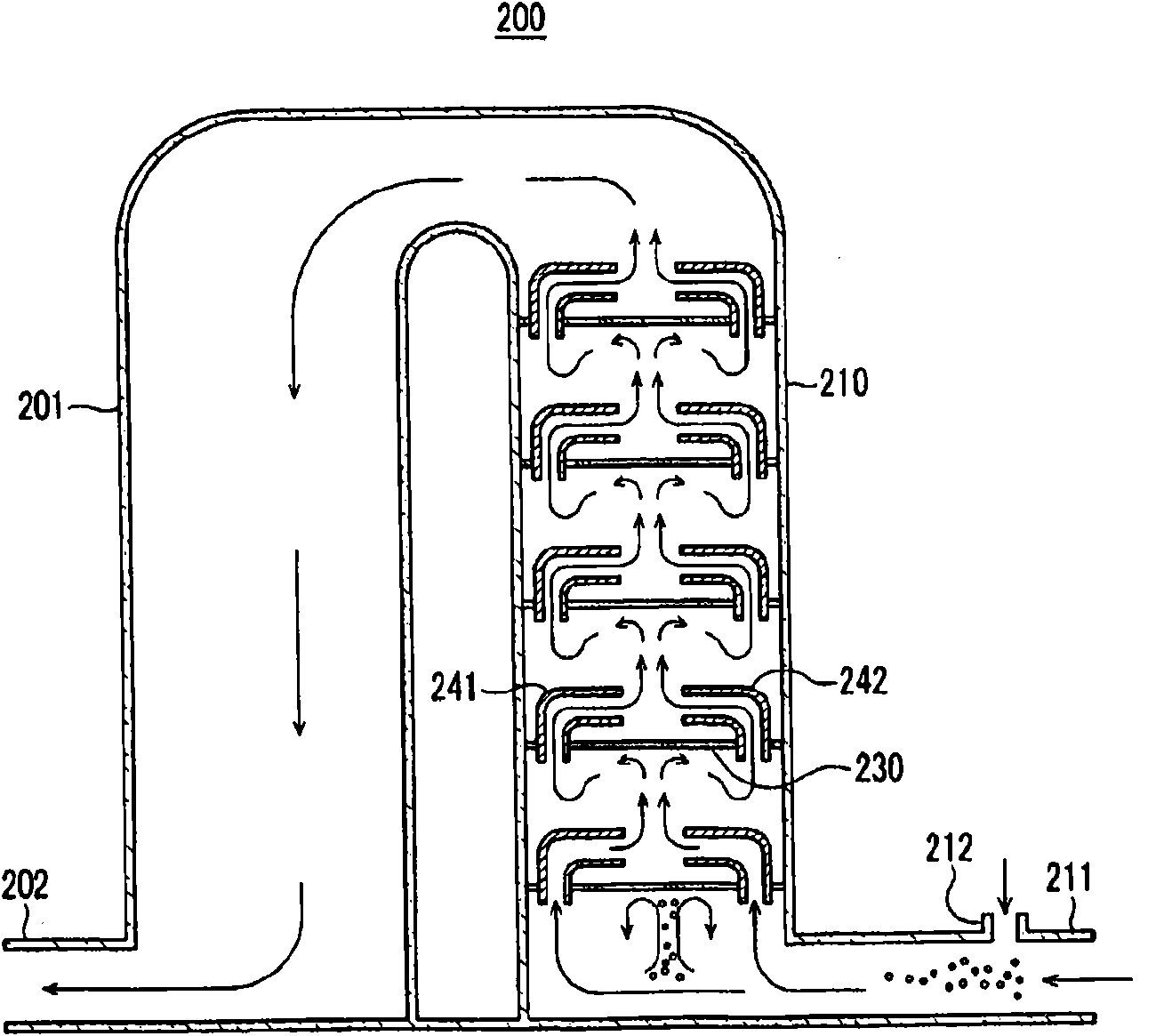

[0030] figure 2 is a cross-sectional view of a dissolving device 200 according to a second embodiment of the present invention, showing the circulation of the first fluid and gas. The circulation of the first liquid and the second liquid is the same as that of the first liquid and the gas.

[0031] In this embodiment, the description of the structure of the vortex guide shell 210, the structure and position of the plate 230 and the vortex guide pipes 241 and 242, the positions of the first supply pipe 211 and the second supply pipe 212, the flow direction of the liquid, and The flow direction of gas is omitted since the above structure has the same function as that of the first embodiment.

[0032] Only the structure of the wear-resistant tank 201 and the connection between the wear-resistant tank 201 and the eddy current guide shell 210 will be described below, wherein the wear-resistant tank 201 and the eddy current guide shell 210 are different from the wear-resistant tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com