Gear device and power transmission apparatus

A power transmission device and gear device technology, which is applied in the direction of gear transmission device, transmission device, gear vibration/noise attenuation, etc., can solve the problems of weight increase and vehicle manufacturing cost increase, and achieve the goal of reducing vibration and noise and suppressing resonance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

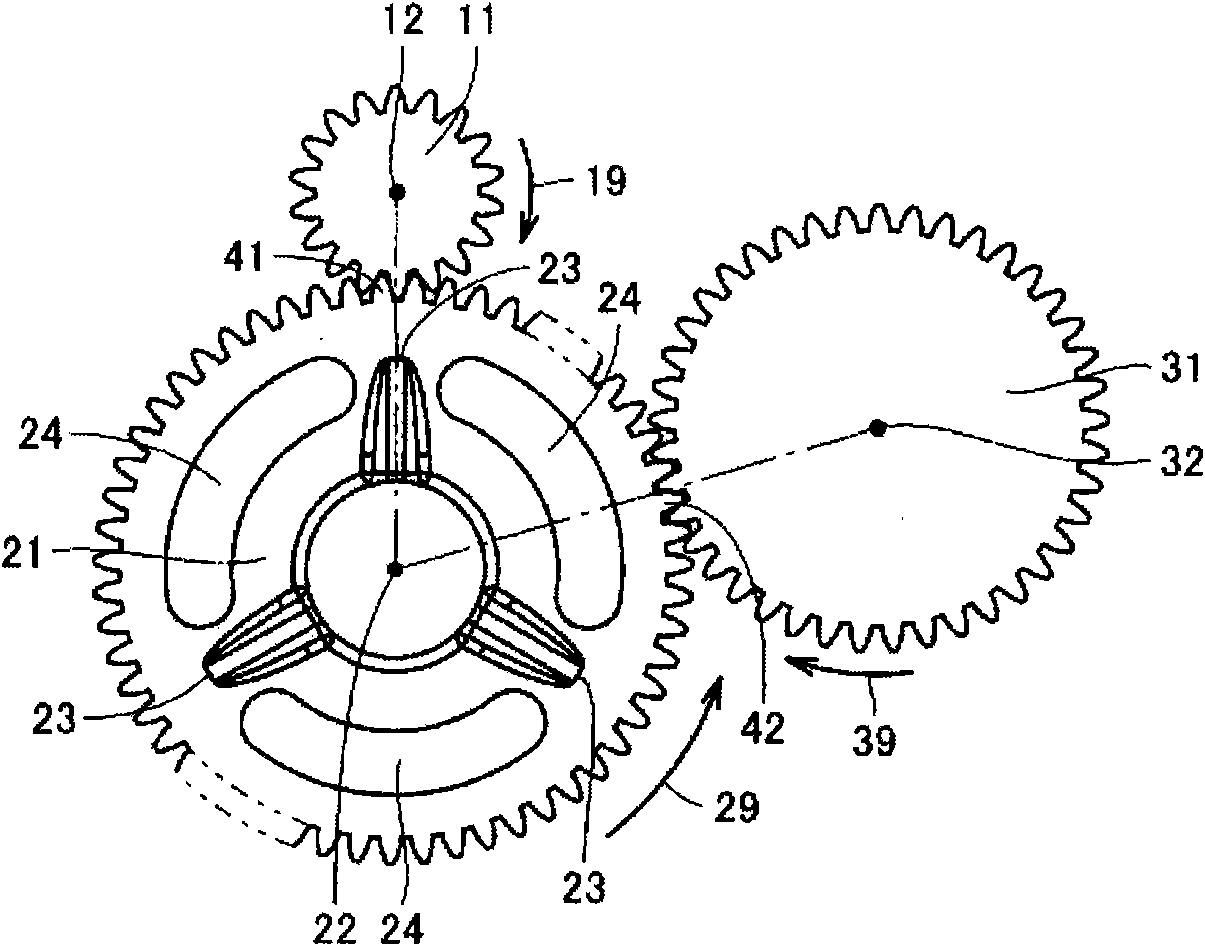

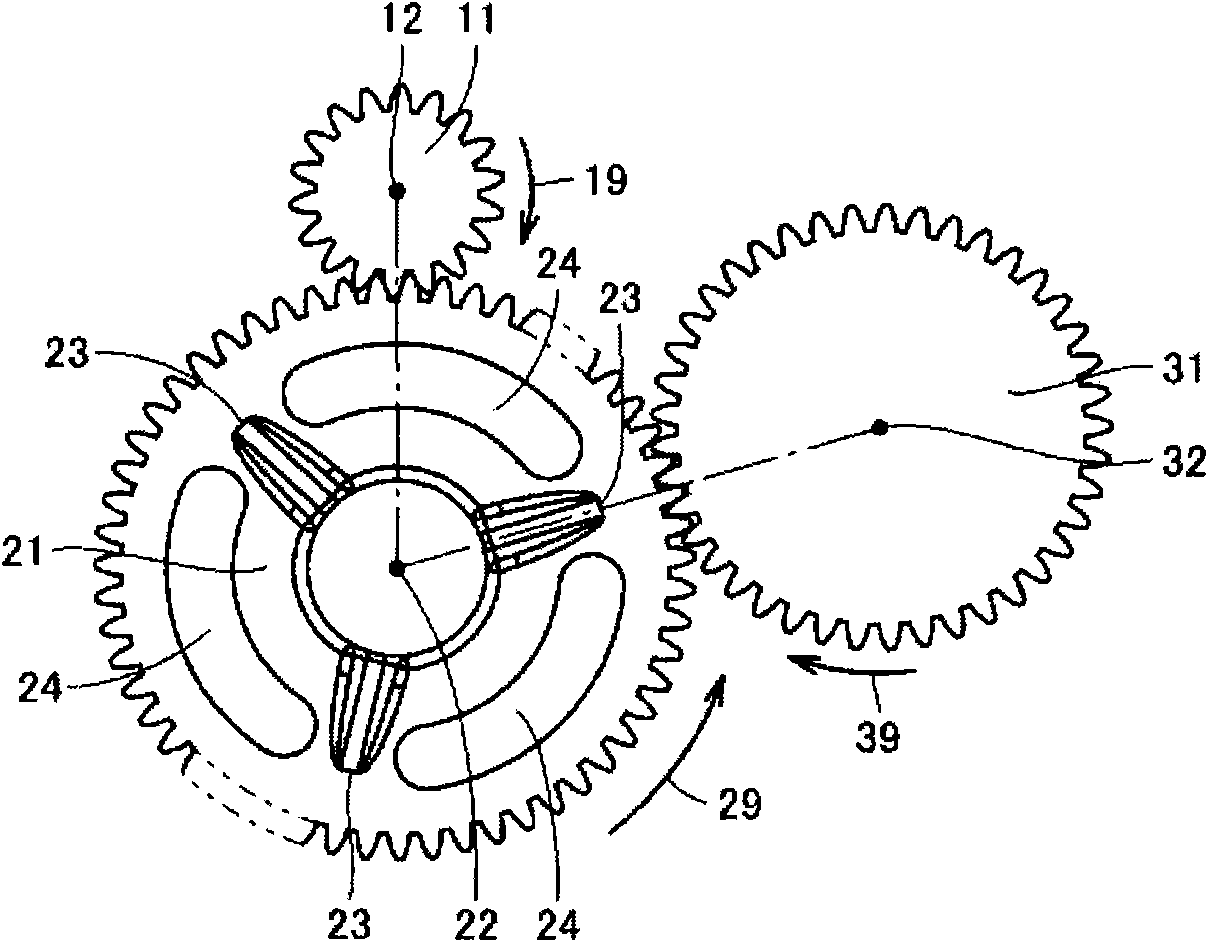

[0067] Next, examples of the present invention will be described. A simulation experiment to calculate the vibration of the entire gear device was performed on a gear device having a three-shaft structure including the second gear having the through hole described in the above-mentioned embodiment. In addition, as a first comparative example, the vibration amount of the entire gear device was calculated for a gear device including a second gear with no through hole formed therein. In addition, as a second comparative example, although the second gear is provided with a through hole, the first gear and the third gear are both arranged in the direction extending from the rotation center of the second gear toward the connecting portion or the through hole. For gear units, the amount of vibration is calculated for the entire gear unit.

[0068] Figure 5A ~ Figure 5C It is a figure which shows the vibration of the gear apparatus of the 1st comparative example. Figure 5AThe vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com