Control system for high-precision liquid filter

A liquid filter and control system technology, applied in fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problems of inability to judge the flushing effect, lack of control to determine which filter to start back flushing, etc. The effect of reducing cost and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

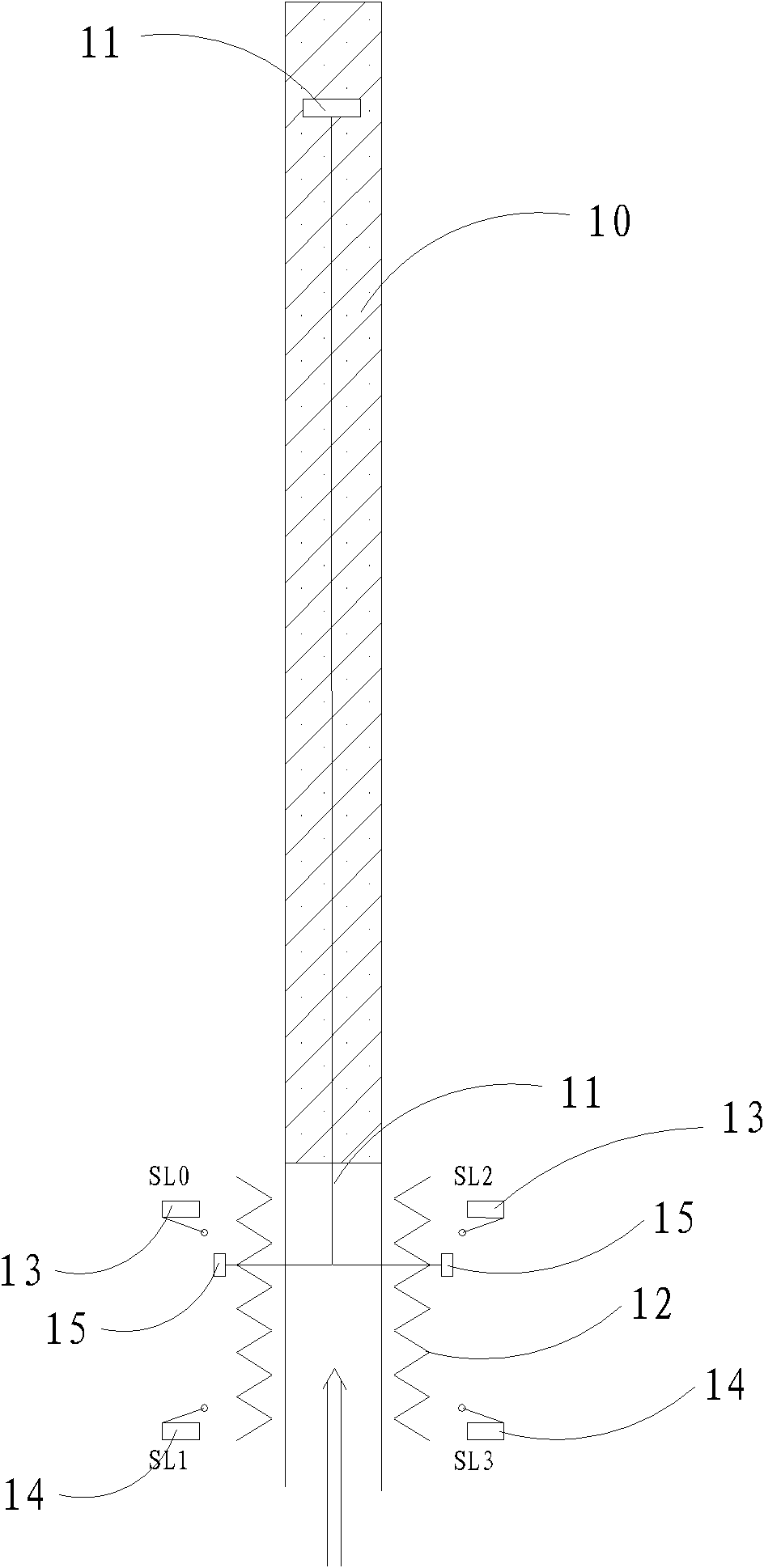

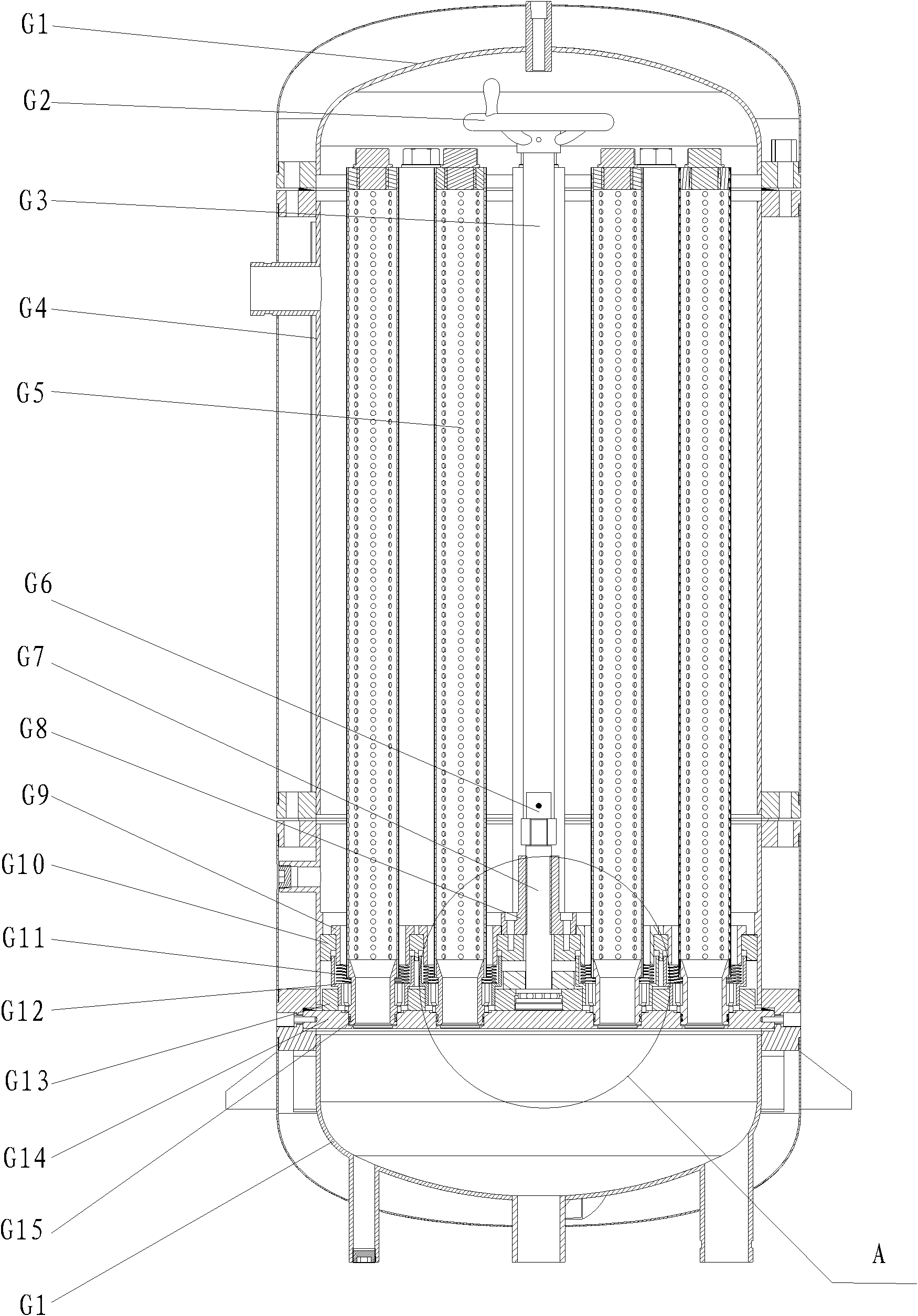

[0028] see figure 1 as well as figure 2 , the control system of the high-precision liquid filter of the present invention includes a filter element connecting rod 11, a spring 12, an upper sensor 13, a lower sensor 14, a contact point 15, a backwash start switch (not shown) for fixedly connecting the filter element 10, A backwash cut-off switch (not shown) and a control device (not shown) for controlling the filter to start backwashing and to turn off backwashing, the filter element connecting rod 11 is fixedly connected to the middle of the spring 12, so The above sensor 13 is located above the spring 12, the lower sensor 14 is located below the spring 12, the end of the filter element connecting rod 11 is fixedly connected to the conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com