All-component steel slag concrete pile and soft foundation treatment construction process thereof

A technology of steel slag concrete and full components, which is applied in infrastructure engineering, sustainable waste treatment, sheet pile walls, etc., can solve the problems of high fly ash price, no full component utilization of steel slag, high cement cost, etc., and achieve protection Environment, save investment, improve the effect of foundation bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

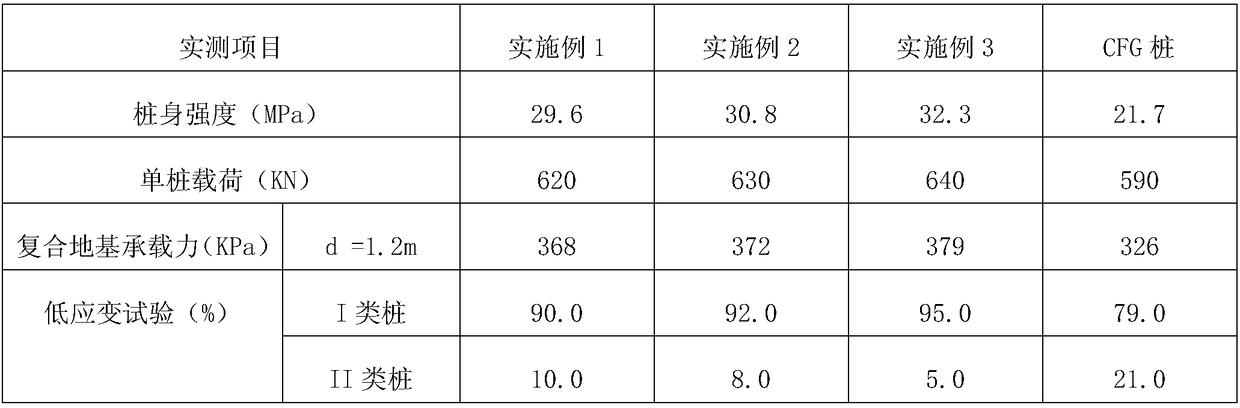

Embodiment 1

[0031] A full-component steel slag concrete pile and its construction technology for treating soft foundations, comprising the following steps:

[0032] S1: The steel slag concrete uses cement, coarse steel slag, fine steel slag, steel slag powder and water as raw materials, mixes in proportion and then adds water; in each cubic meter of mixture, the weight of cement, steel slag powder, coarse steel slag, and fine steel slag The ratio is 278Kg: 70Kg: 1185Kg: 677Kg;

[0033] Among them, the amount of water used is controlled at a concrete slump of 50-80mm; the requirements for materials are: ordinary portland cement with a cement label of 42.5R; The expansion ratio is less than or equal to 2%; the particle size of the coarse steel slag is 5-20mm; the particle size of the fine steel slag is less than 5mm; the specific surface area of the steel slag powder is 460m 2 / Kg or more, and meet the technical requirements of "Steel Slag Powder Used in Cement and Concrete" (GB / T 20491)...

Embodiment 2

[0045] A full-component steel slag concrete pile. The steel slag concrete pile is mixed with cement, coarse steel slag, fine steel slag, steel slag powder and water as raw materials to obtain an admixture, wherein, in each cubic meter of admixture, cement, steel slag powder, The weight ratio of coarse steel slag and fine steel slag is 270:65:1170:670. The rest of the methods are consistent with Example 1.

Embodiment 3

[0047] A full-component steel slag concrete pile. The steel slag concrete pile is mixed with cement, coarse steel slag, fine steel slag, steel slag powder and water as raw materials to obtain an admixture, wherein, in each cubic meter of admixture, cement, steel slag powder, The weight ratio of coarse steel slag and fine steel slag is 280:75:1190:682. The rest of the methods are consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com