Metallurgical liquid tank

A liquid tank and tank mouth technology, applied in the field of metallurgical liquid tanks, can solve problems such as poor thermal insulation effect, and achieve the effect of convenient overhaul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

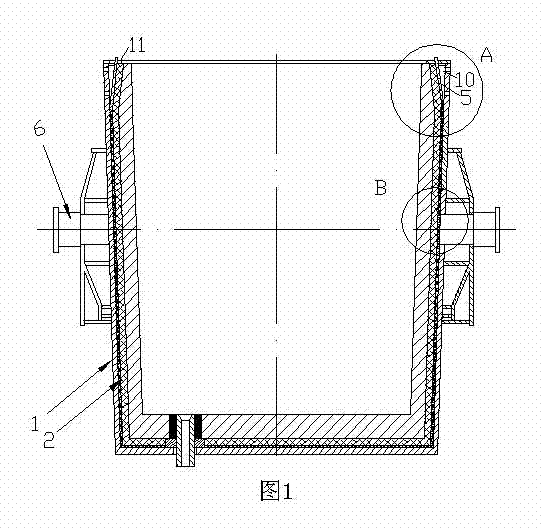

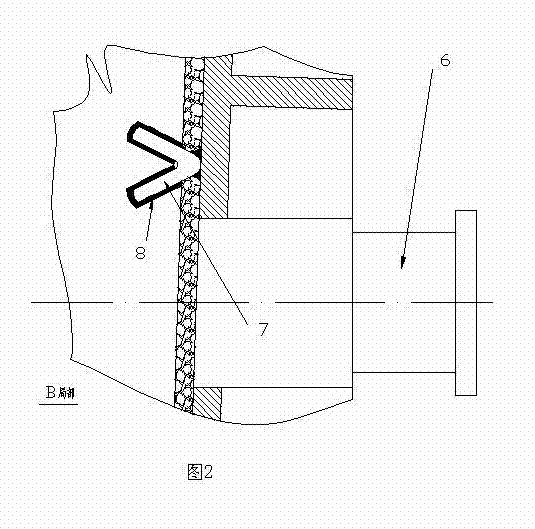

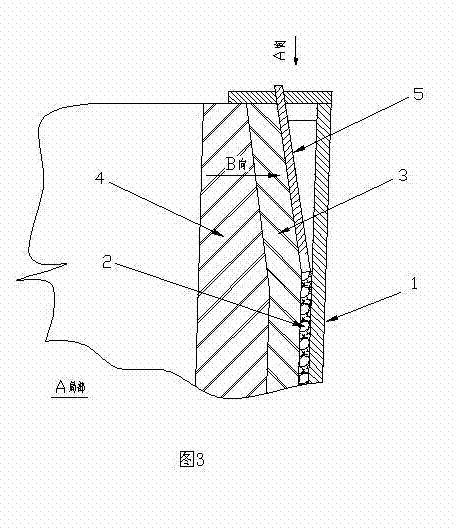

[0016] As shown in the figure, a metallurgical liquid tank includes a tank shell 1, a trunnion 6, a tank mouth flange 11, an insulation layer 2, a permanent layer 3, a refractory working layer 4 and a permanent layer material anchor nail 7, which is characterized in that : the inner wall of the tank mouth of the tank shell 1 is provided with a plurality of tank mouth flange anchor plates 5, and the tank mouth flange 11 has an anchor plate passage hole corresponding to and matched with the tank mouth flange anchor plate 5, and anchoring The plate 5 is higher than the upper surface of the tank mouth flange 11, and the tank mouth flange 11 is fixed on the upper port of the tank mouth by discontinuous welding with each tank mouth flange anchor plate 5, and the tank mouth flange is anchored The plate 5 gradually moves away from the inner surface of the tank shell 1 upwards from the connection with the inner surface of the tank shell 1 , and a reinforcing rib 10 is arranged between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com