Anti-counterfeiting electronic tag and manufacturing method thereof

A technology of electronic tags and manufacturing methods, which is applied to recording carriers used in machines, instruments, computer parts, etc., and can solve the problems of increasing the fragility of tags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

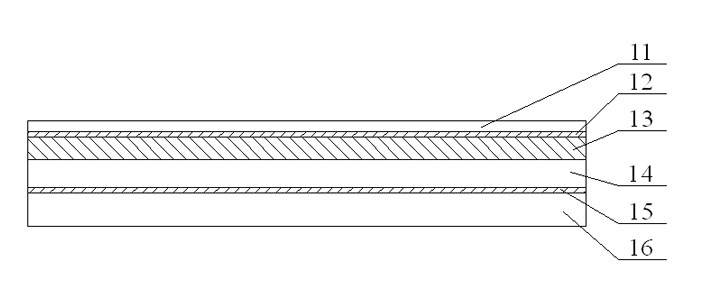

[0023] Taking the etched antenna as an example, the base material of the antenna is made of PET polymer, and the material of the antenna is made of aluminum foil.

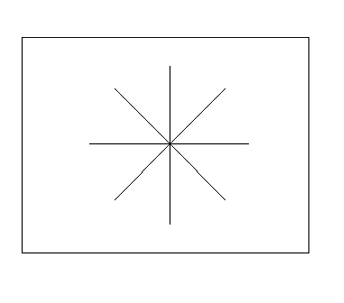

[0024] According to attached figure 1 , 2 , first die-cut the antenna base material—PET polymer 14 with a thickness of 0.04mm. figure 2 , the die-cut depth is full cut through. The die-cutting knife should be kept sharp and the edge of the knife should be as narrow as possible to prevent the edge of the PET cut from being squeezed and becoming uneven.

[0025] attached figure 2 The linear radial incision shown is a form that is easier to realize, and it is not limited to this one in actual use, and continuous curves (such as S shape, W shape, etc.) or other irregular shapes can also be used.

[0026] The surface of the PET polymer 14 is coated with epoxy glue, and bonded together with the aluminum foil 13 with a thickness of 0.03mm. Dry the compounded semi-finished product to cure the epoxy glue.

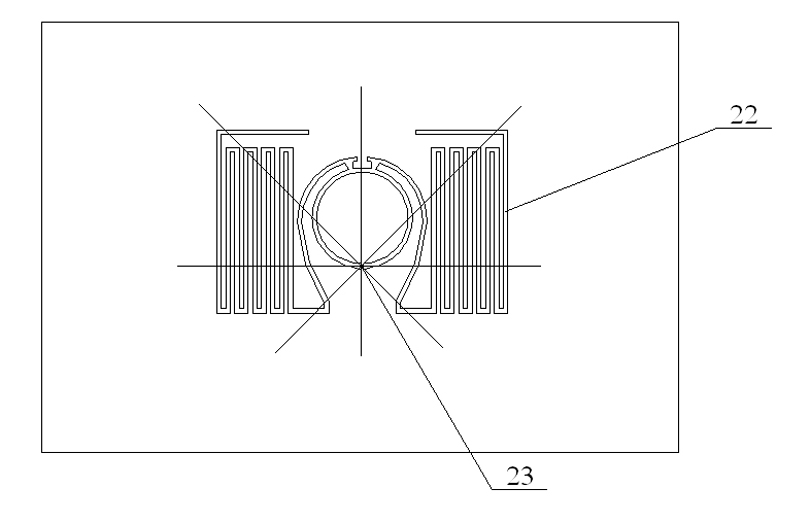

[0027] N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com