Waterproof rolling bearing

A technology of rolling bearings and bearing sleeves, applied in the directions of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of inability to meet outdoor motors and high cost, and achieve the effects of simple structure, improved protection level, and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings.

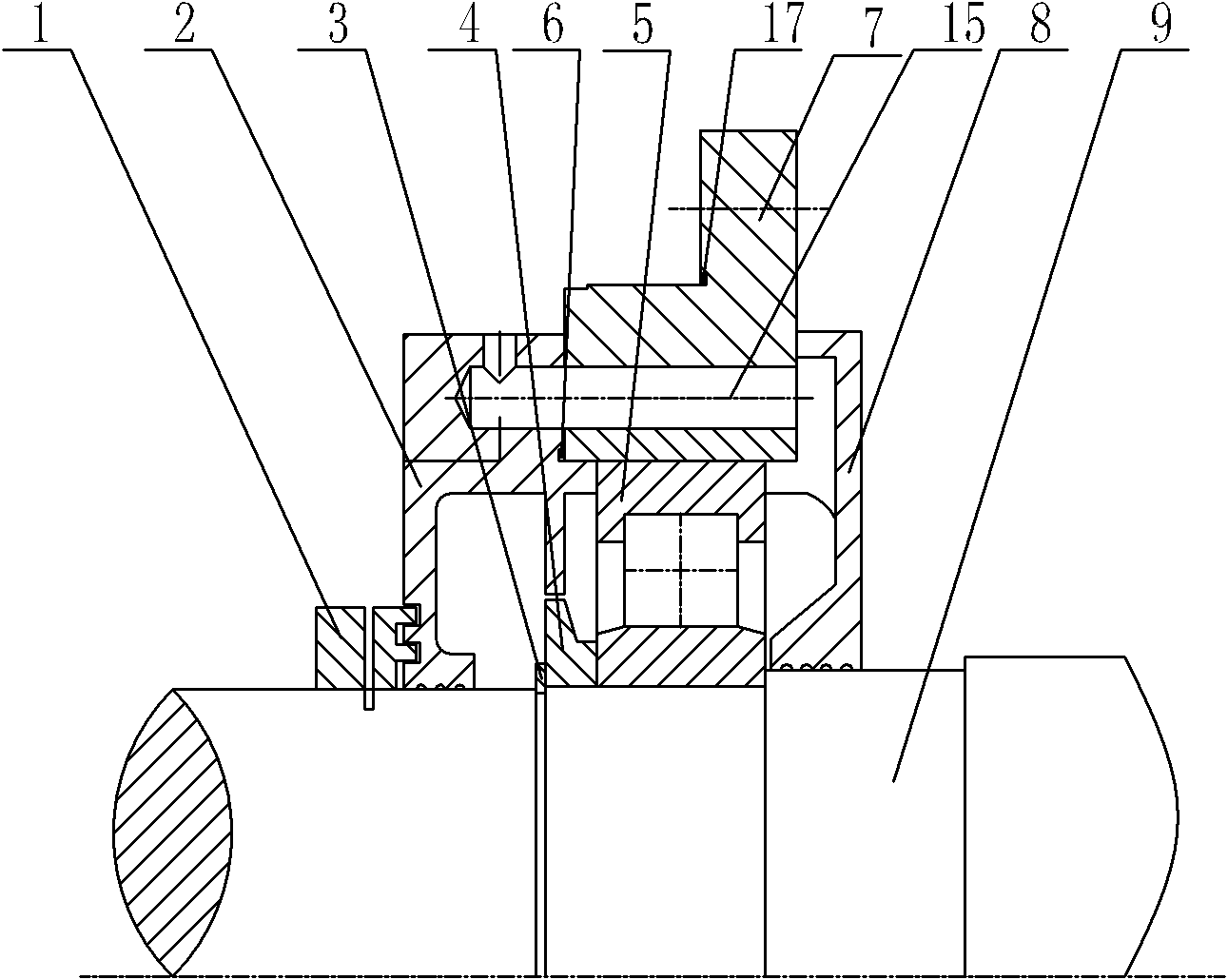

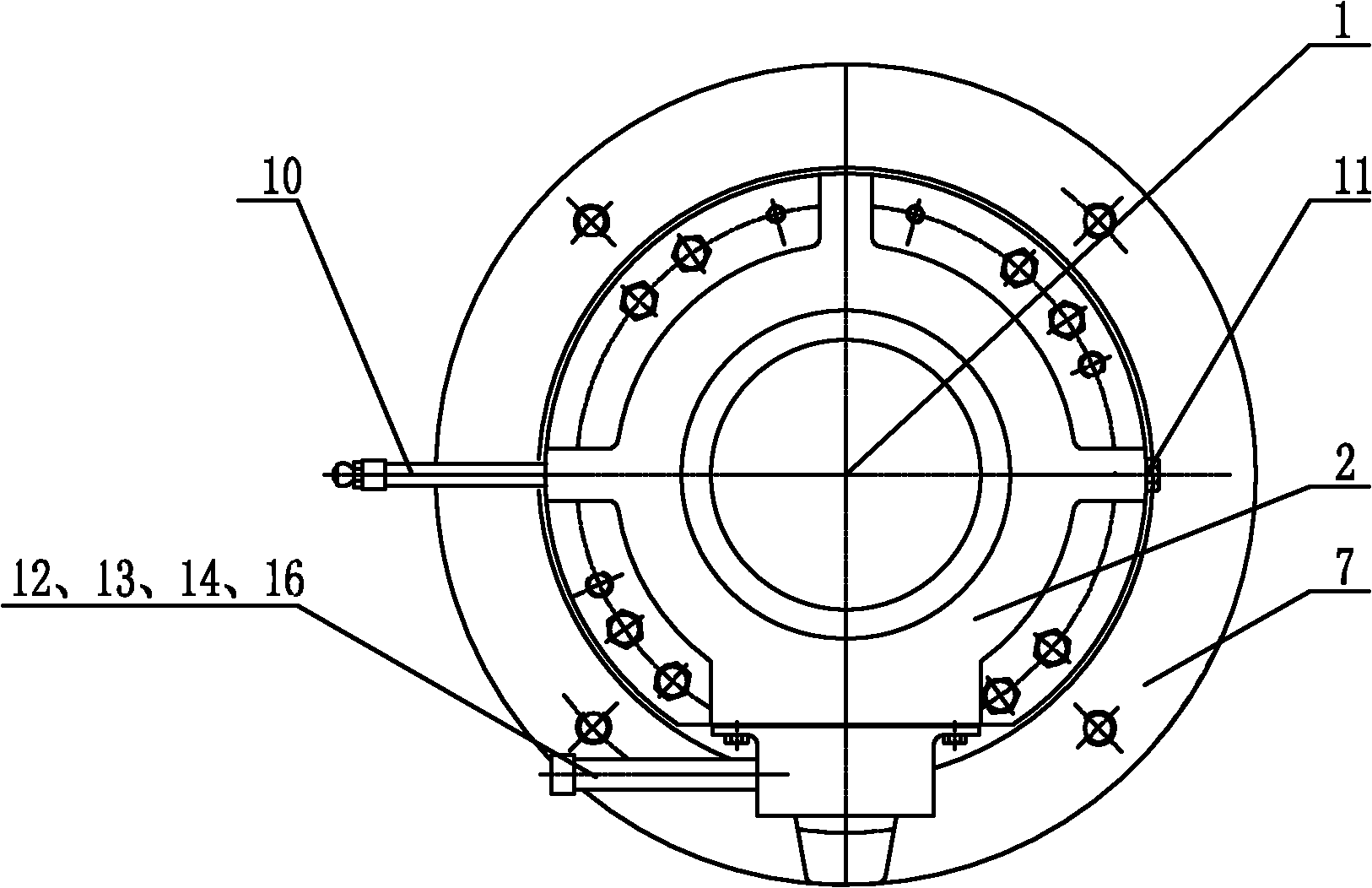

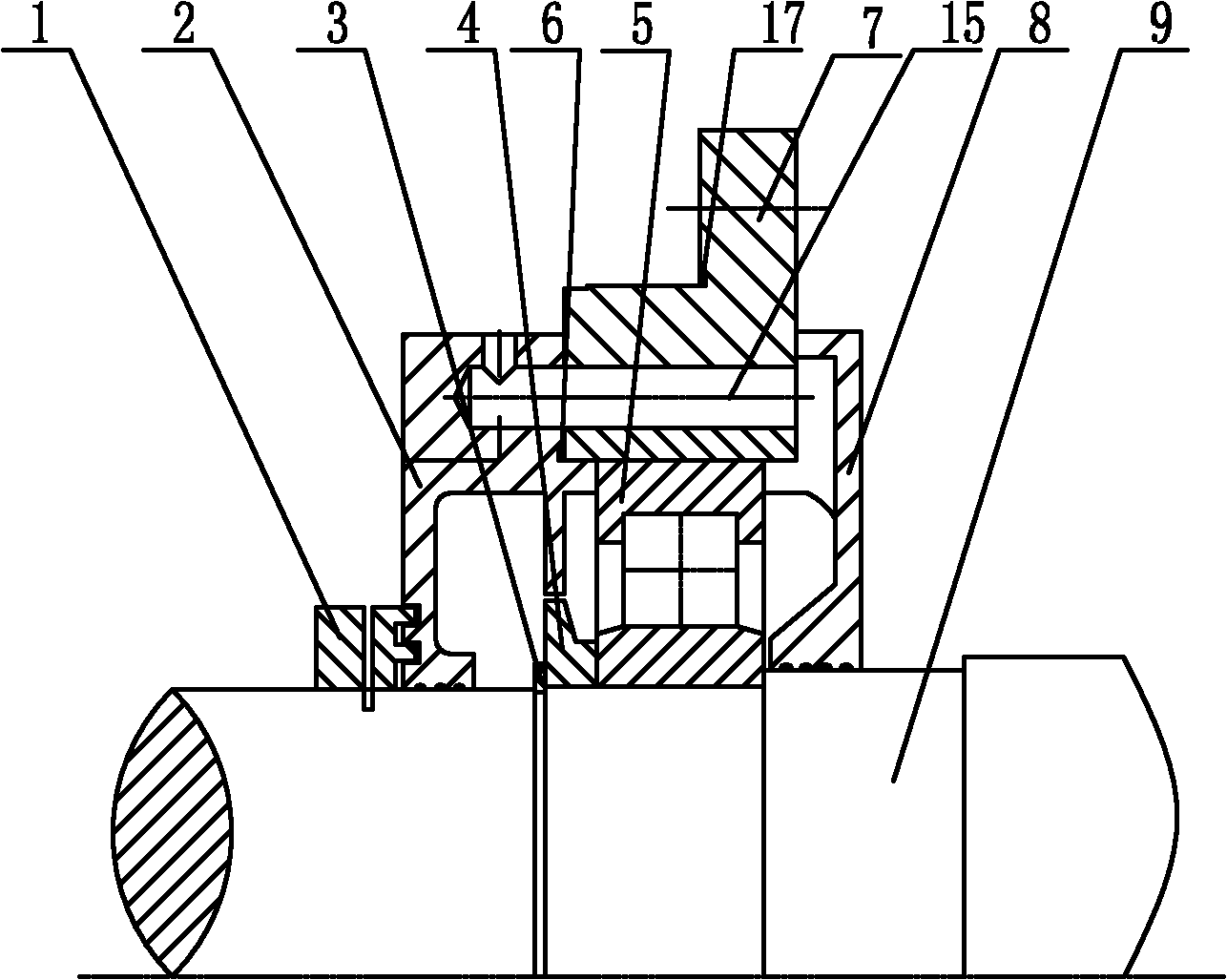

[0013] Such as Figure 1 ~ Figure 2 Shown: Waterproof rolling bearing includes labyrinth ring 1, bearing outer cover 2, shaft spring retaining ring 3, oil slinger 4, rolling bearing 5, first nitrile rubber round bar 6, bearing sleeve 7, bearing inner cover 8, shaft 9 , Oil injector 10, bolt 11, oil guide tube 12, box 13, gasket 14, hexagon bolt 15, spring washer 16, second nitrile rubber round strip 17, etc.

[0014] The present invention includes a rolling bearing 5 and an oil sling 4 sleeved on a shaft 9, a bearing outer cover 2 and a bearing inner cover 8 are respectively arranged on both sides of the rolling bearing 5, and a bearing sleeve 7 is arranged on the outer ring of the rolling bearing 5; A first nitrile rubber round strip 6 is arranged between the outer cover 2 and the bearing sleeve 7; a second nitrile rubber round strip 17 is arranged on the outer surface of the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com