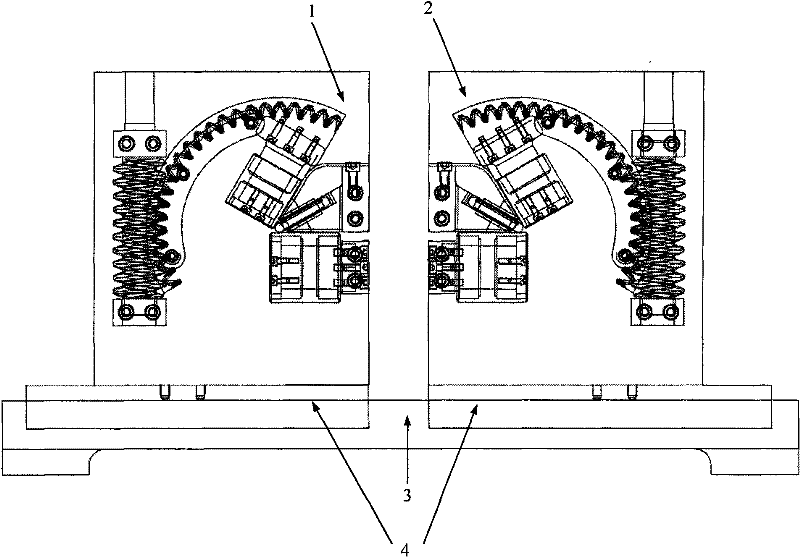

Multi-roller flexible roll formation calibrating device with adjustable roll angle

A calibration device and adjustable technology, which is applied in the field of multi-roller flexible roll forming calibration device with adjustable roll angle, can solve the problems of inconvenience and high cost, achieve good stability, reduce processing cost and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

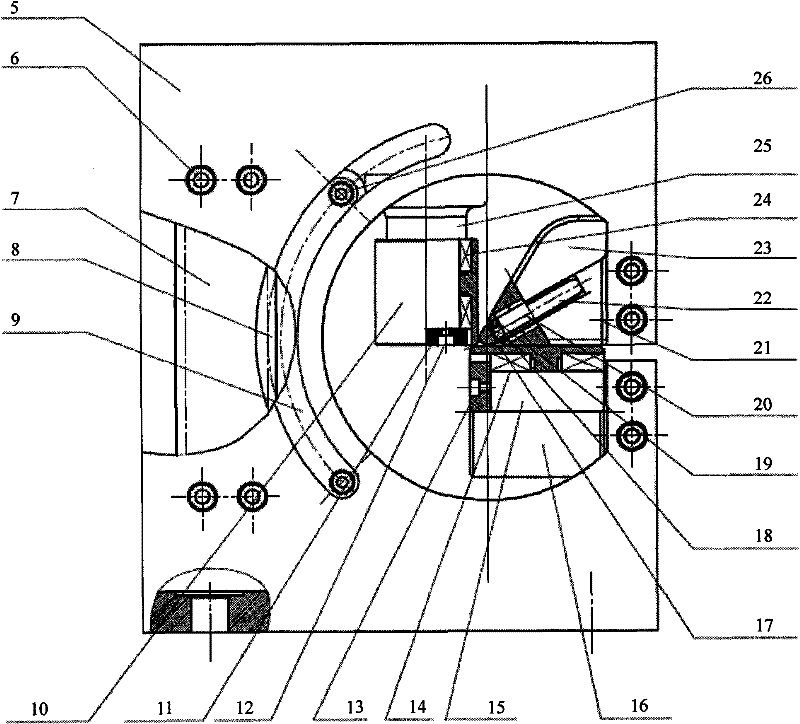

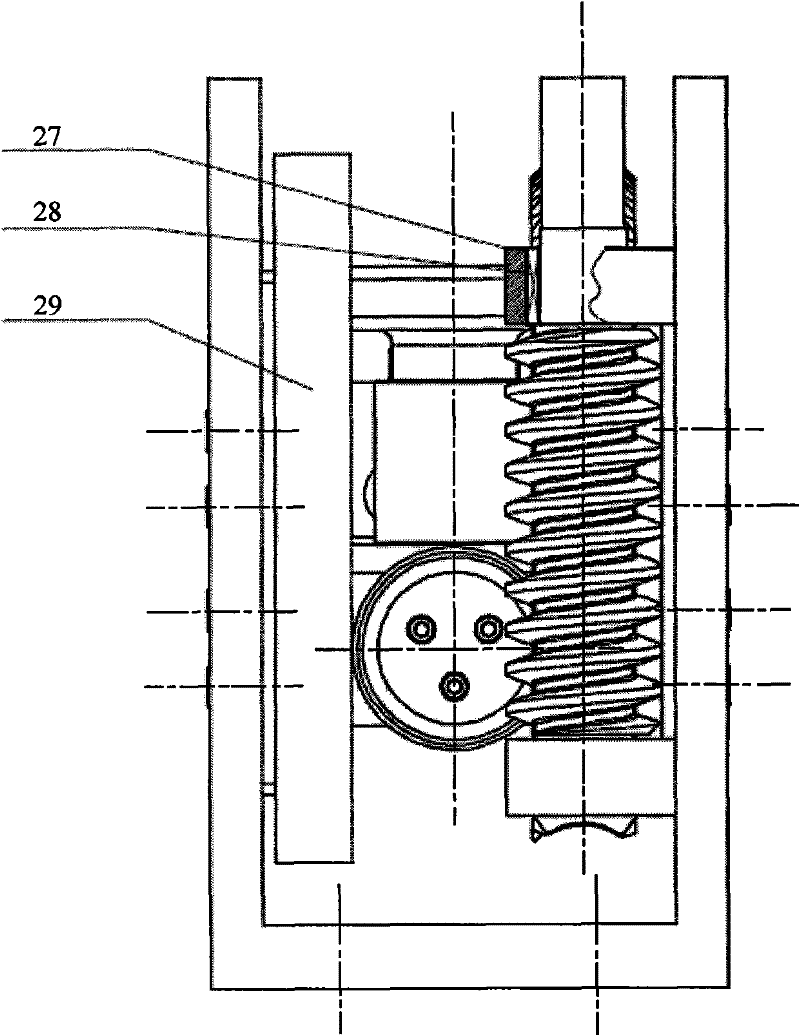

Method used

Image

Examples

Embodiment 1

[0028] At room temperature, three frames are used for forming, and the forming angles of each frame are 30°, 60°, and 90° in turn, and the frame spacing is 250mm. The forming material is Dogal 800DP, the section is a symmetrical U-shaped section, the length of the plate is 600mm, the width is 72.32mm, the thickness is 1.2mm, and the forming corner radius R is 1.5mm. The forming speed was set at 5 m / s.

[0029] After the plate comes out of the roll, the plate will rebound, and the rebound angle detected by the machine vision detection device is 1.29°, such as Figure 5 Shown in 30. The data detected by the machine vision detection device is calculated by a specific algorithm to obtain the straightening angle of the roll of the calibration device. The control mechanism controls the motor to drive the worm 8 to rotate, and then drives the worm wheel 9 and the cage 29 to slide along the guide rail 10 to adjust the angle of the adjustable frame. The bending angle of the plate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com