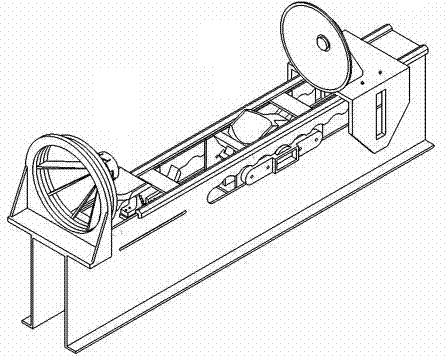

Mechanical supporting mechanism of bamboo splitting machine

A support mechanism and mechanical technology, applied in wood processing equipment, wood splitting devices, manufacturing tools, etc., can solve the problems of low degree of automation, time-consuming and low efficiency, and achieve the benefits of maintenance and management, easy lifting and lowering, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

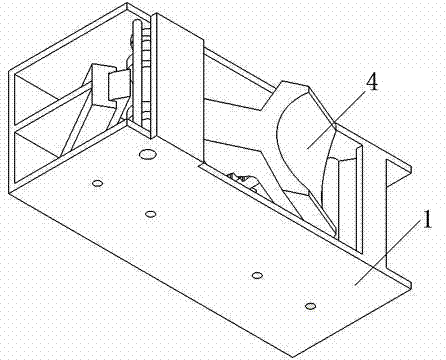

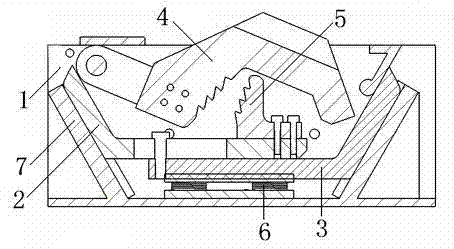

[0018] refer to Figure 1-3 , the mechanical support mechanism of the bamboo breaking machine, which is installed on the bamboo breaking machine, and includes a box body 1, a slider is installed in the box body 1, and the slider is composed of a V-shaped left slider 2 and a right slider 3 , the left slider 2 and the right slider 3 are fixedly connected, the box body 1 is hinged with a support rod 4 supporting bamboo, and the support rod 4 is supported by a support block 5 fixed on the slider, and the slider Below the block is provided a spring plate 6 supporting it.

[0019] The support block 5 and the support rod 4 are supported by helical tooth engagement.

[0020] Both sides of the box body 1 are provided with inclined slide rails 7, and the slope parts of the left slide block 2 and the right slide block 3 can be slid along the slide rails 7 and installed in the slide rails 7 respectively.

[0021] During use, one of the bamboo-breaking machine mechanical support mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com