Precision worm gear-worm speed reducer

A technology of worm gear and reducer, which is applied in the direction of mechanical equipment, gear transmission, belt/chain/gear, etc. It can solve the problems such as difficulty in controlling the radial adjustment of worm gear pairs, small adjustment of meshing clearance, and skewed worm axis. It achieves the effect of compact structure, high repeat positioning accuracy and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

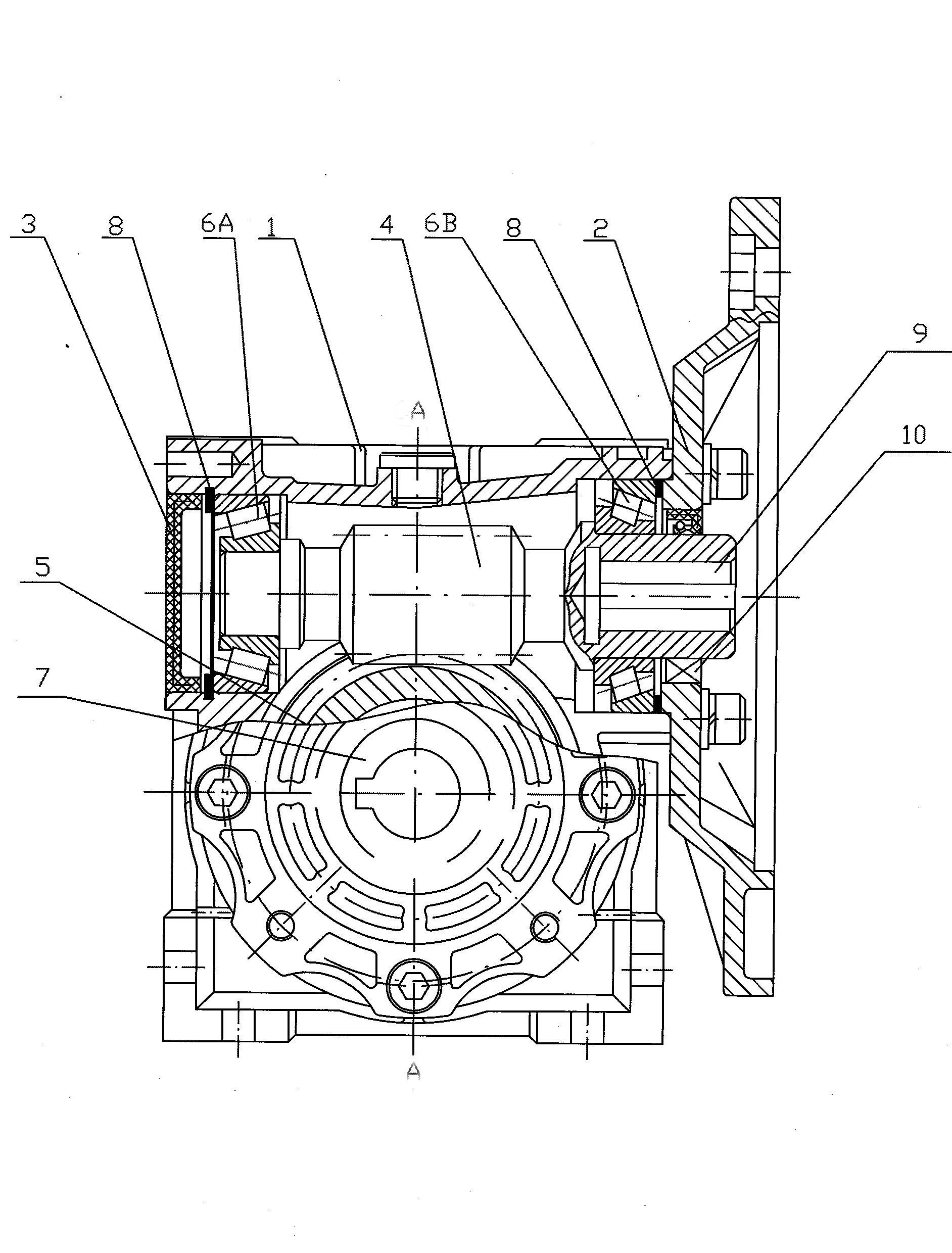

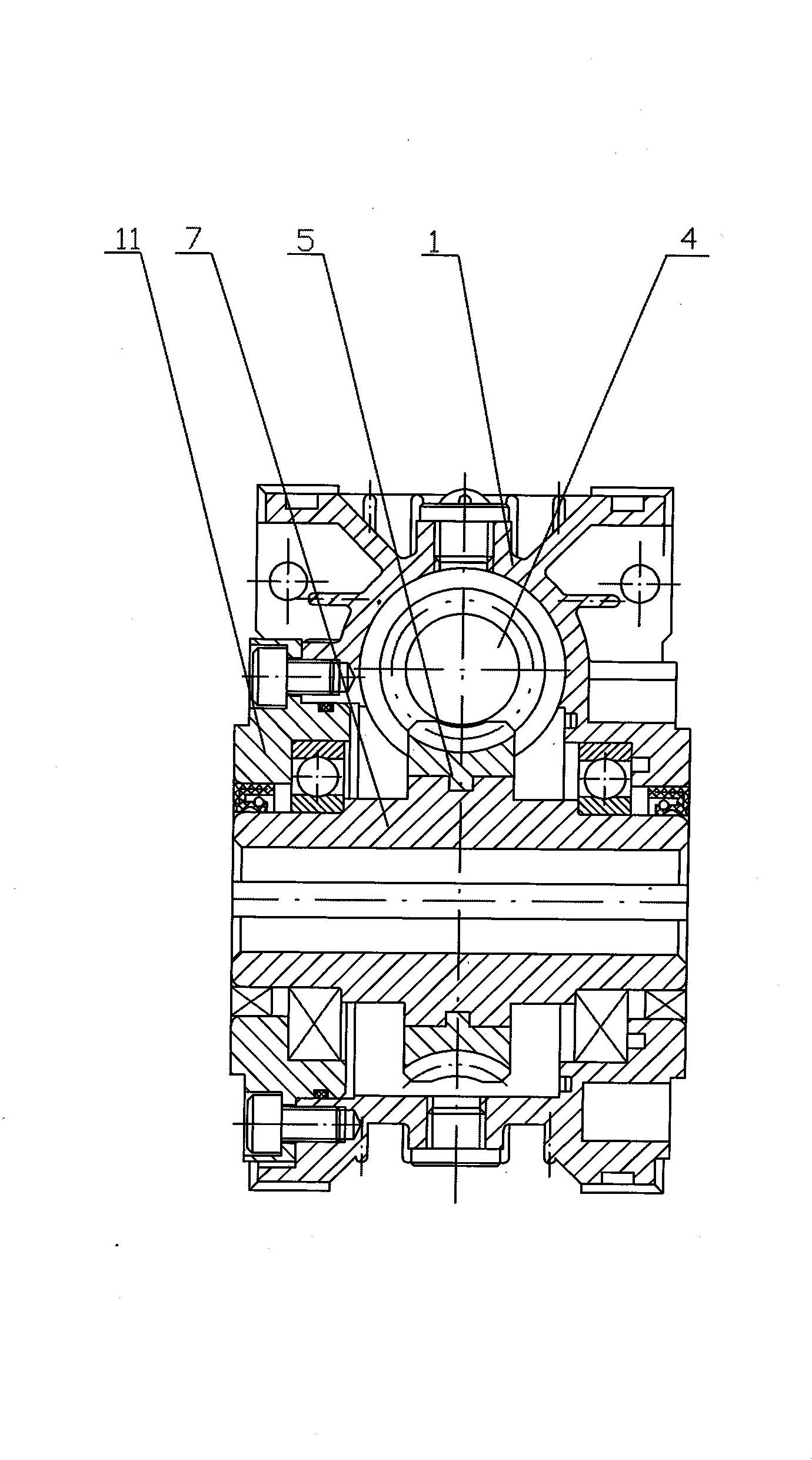

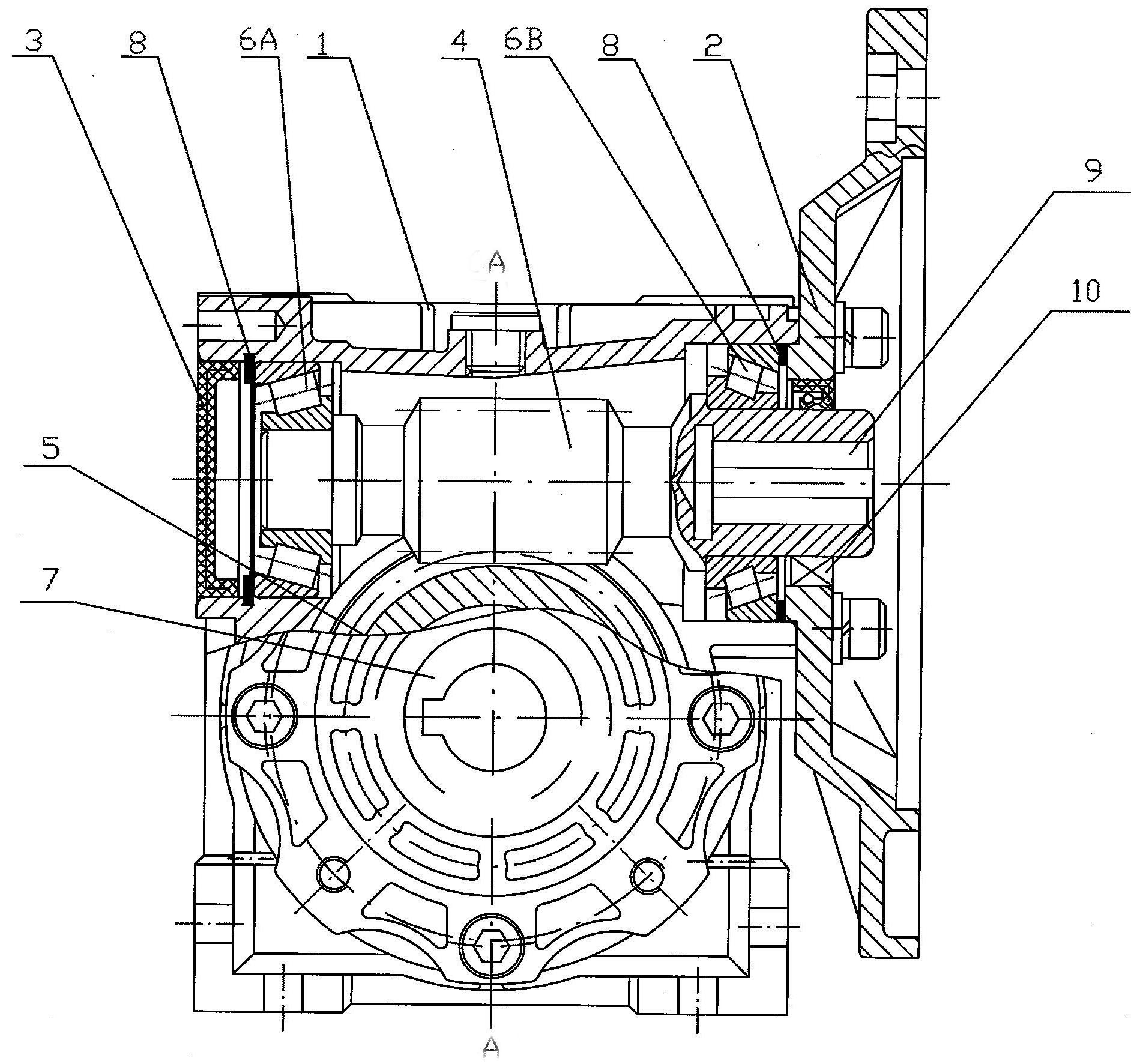

[0011] As shown in the figure, the present invention includes a box body 1, an end cover 11, an input flange 2 and a cover 3 respectively fixed on both sides of the box body 1, and a double-lead worm gear pair is arranged in the box body 1, wherein the double-lead The worm 4 is externally connected to the input shaft, the two ends of the double-lead worm 4 are supported in the box 1 by bearings, the worm gear 5 drives the output bushing 7, and the double-lead An automatic adjustment spring 8 is arranged between the bearing 6B at the front end of the worm screw 4 and the input flange 2 . The double-lead worm 4 controls the adjustment amount through the automatic adjustment spring 8, and the adjustment is accurate. The double-lead worm is also called the double-lead worm with variable tooth thickness. The left and right sides of the double-lead worm teeth have different leads, while the leads on the same side are equal. The reason is that the double-lead The tooth thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com