Method for adjusting installation position error of T-shaped truss

A technology of installation position and adjustment method, which is applied in the field of measurement and achieves the effects of meeting high-precision installation requirements, simple analysis model, and simple and effective method for precise adjustment of errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

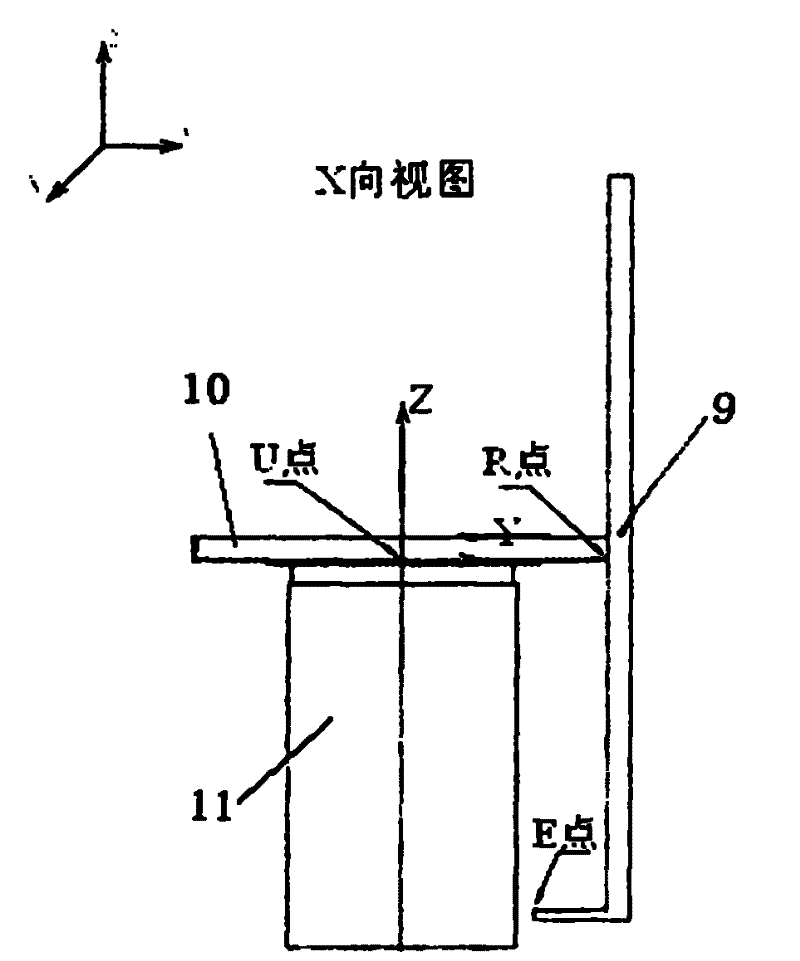

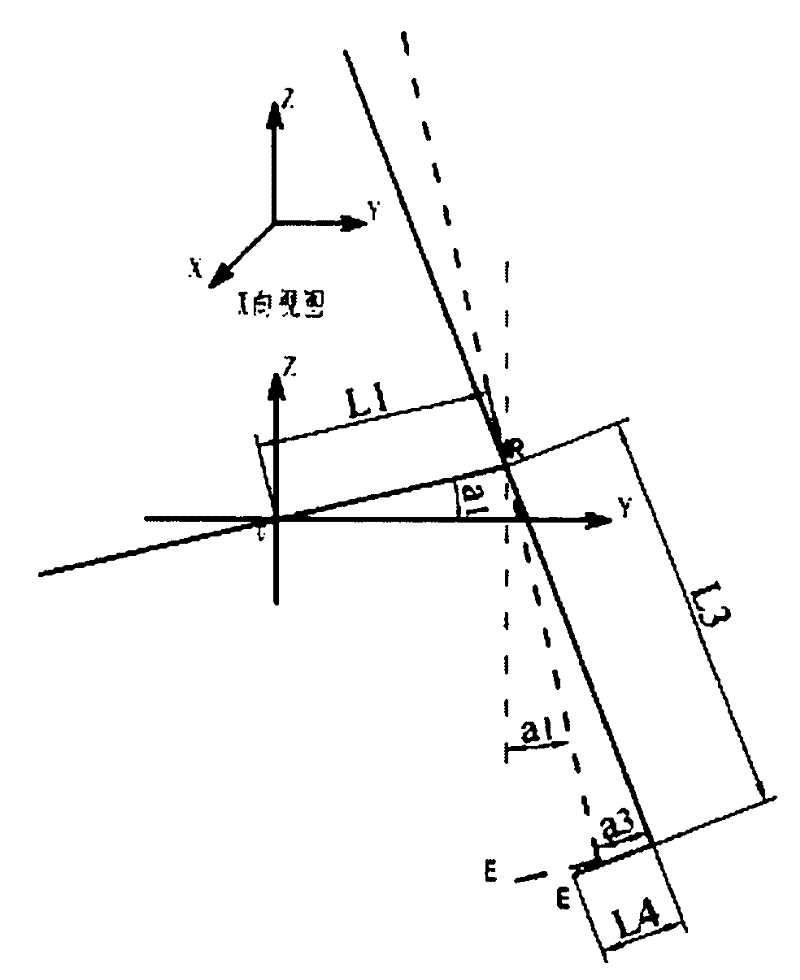

[0020] The adjustment method and process of the installation position error of the entire T-shaped structure truss will be described in detail below in conjunction with the accompanying drawings.

[0021] The specific implementation steps of the adjustment method of the T-shaped structure truss installation position error proposed by the present invention are as follows:

[0022] 1. Based on the measurement data, establish a geometric model for position error analysis of point E of the main truss.

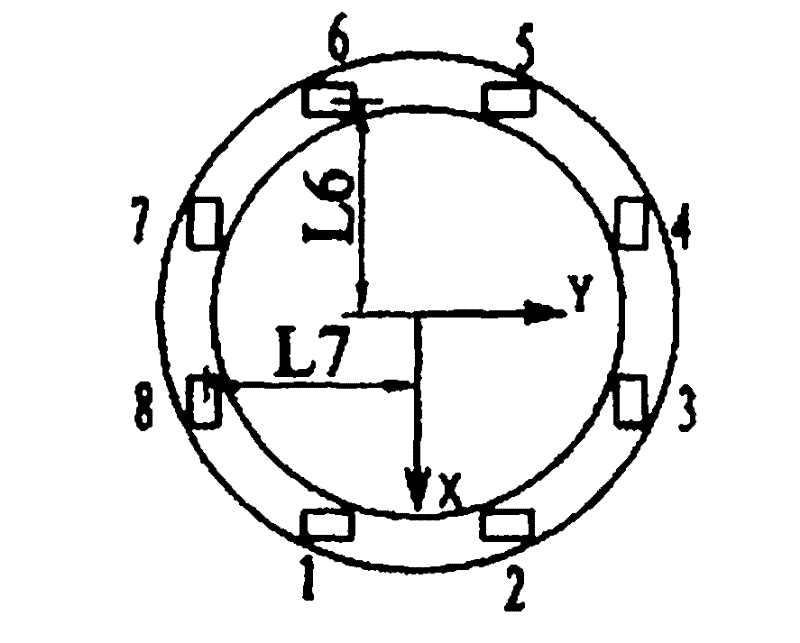

[0023] Such as image 3 with 4 As shown, the position error of the point E of the main truss is the joint result of the installation angle deviation of the cross truss 10' deviating from the ideal position and the installation angle deviation of the vertical truss 9' deviating from the ideal position. Using the principle of vector synthesis, the installation angle deviation of the cross truss 10' is decomposed into the rotation around the X axis and the rotation around the Y axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com