Method of measuring reinforced concrete creep stress by using engineering safety monitoring rebar stressometer

A technology of reinforced concrete and steel stress, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problems of opposite signs, unable to fully reflect the actual state of the structure, and the difference between the calculated stress and the measured stress of concrete is large.

Inactive Publication Date: 2011-03-23

BEIJING MILLENNIUM ENG TECH CO LTD +1

View PDF4 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Existing technologies often solve the above problems from the perspective of the simplified constraint state of the structure and the single influencing factor affecting the stress of the reinforced con

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a method of computing reinforced concrete creep stress which obtains constraint factors reflecting the actual constraint status of a reinforced concrete structure according to the rebar stress actually measured by a rebar stressometer and further finding the relationship between the reinforced concrete creep stress and the rebar stress. Compared with the method of obtaining the concrete stress through complicated mathematic changes by using buried complicated strainometer and non-stressometer in the prior art, the invention has the advantages of higher accuracy and economy. The invention provides powerful reference for reflecting the status of the internal force of the composite material reinforced concrete and evaluating the safety of the reinforced concrete structure.

Description

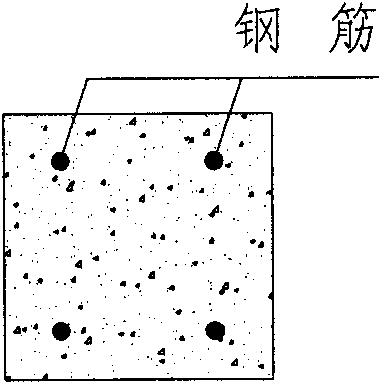

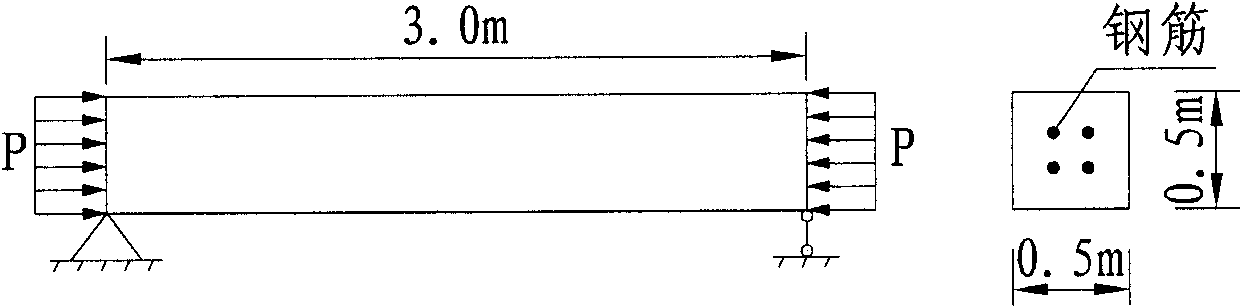

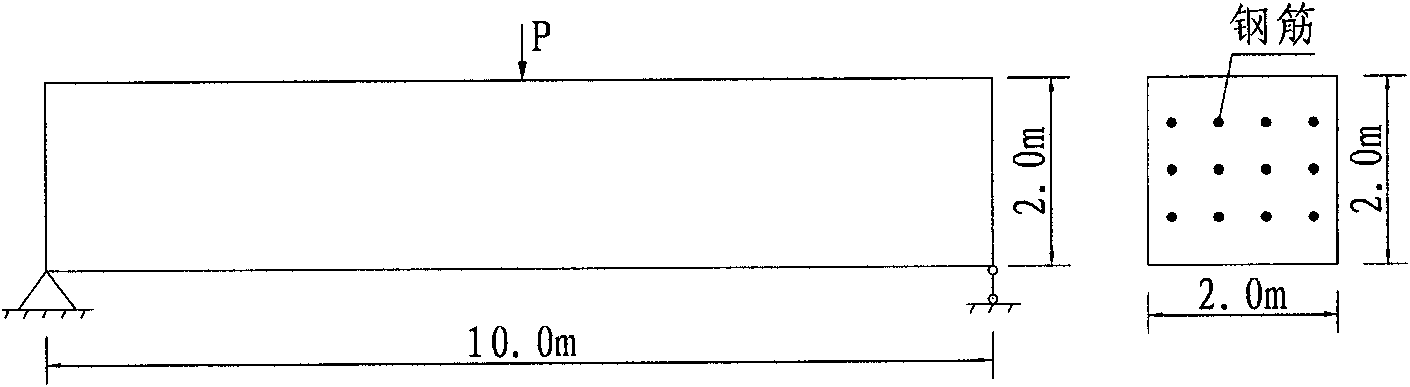

technical field [0001] The invention provides a method for measuring the creep stress of reinforced concrete with a steel stress gauge in a reinforced concrete structure, which is suitable for measuring the creep stress of the reinforced concrete structure under external force load, temperature load, autogenous volume deformation, creep and dry shrinkage load Measurement. Background technique [0002] Reinforced concrete structure is a commonly used structural form in civil engineering such as water conservancy, hydropower, transportation and industrial civil buildings. This structure is composed of two materials: steel bar and concrete, which can give full play to the tensile capacity of steel bar and the compressive capacity of concrete. , has a high carrying capacity. Since the reinforced concrete structure is composed of steel and concrete, in addition to the stress generated by the external load, the difference in the thermal and mechanical properties of the steel and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01L1/00G01N3/00

Inventor 郭晨张国新王振红刘爱梅黄涛江少刚

Owner BEIJING MILLENNIUM ENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com