Cement-based material axial pressure creep testing device capable of regulating and controlling temperature, humidity and load

A technology for cement-based materials and testing devices, which can be used in measuring devices, using stable tension/pressure to test material strength, analyzing materials, etc., and can solve problems such as difficulty in achieving accuracy and convenience, and difficulty in maintaining constant stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

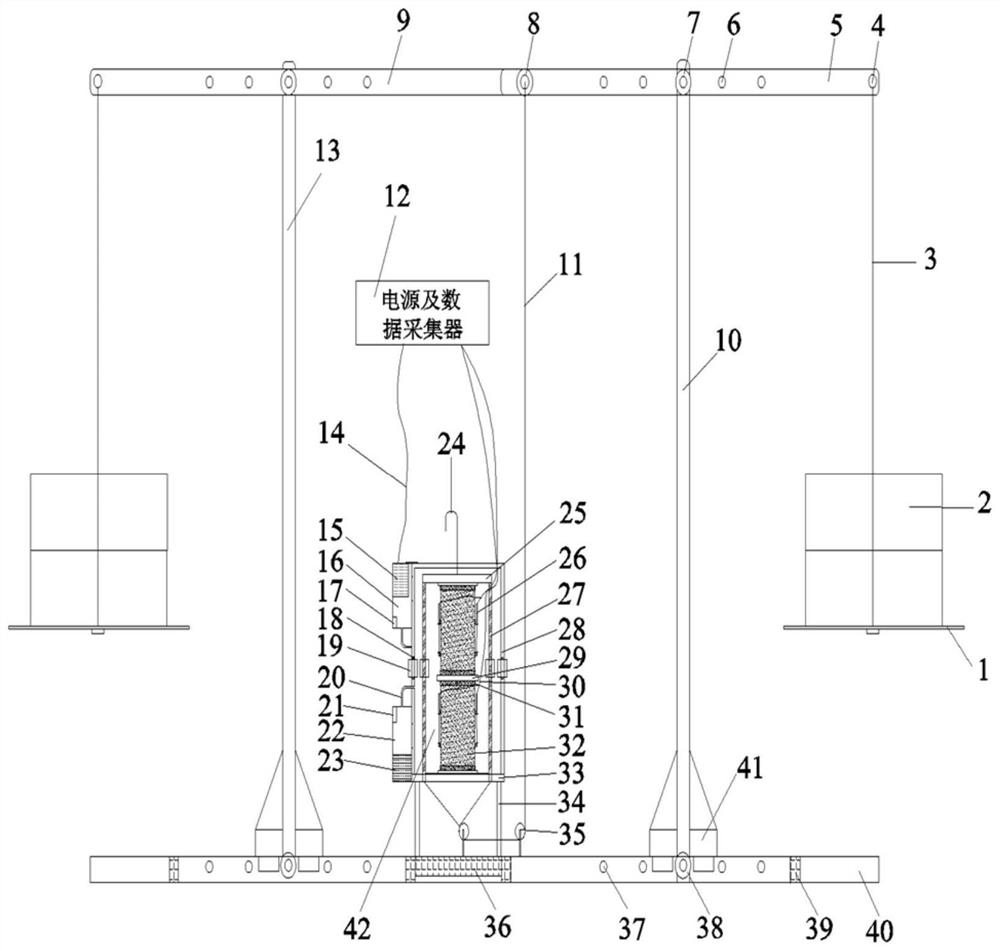

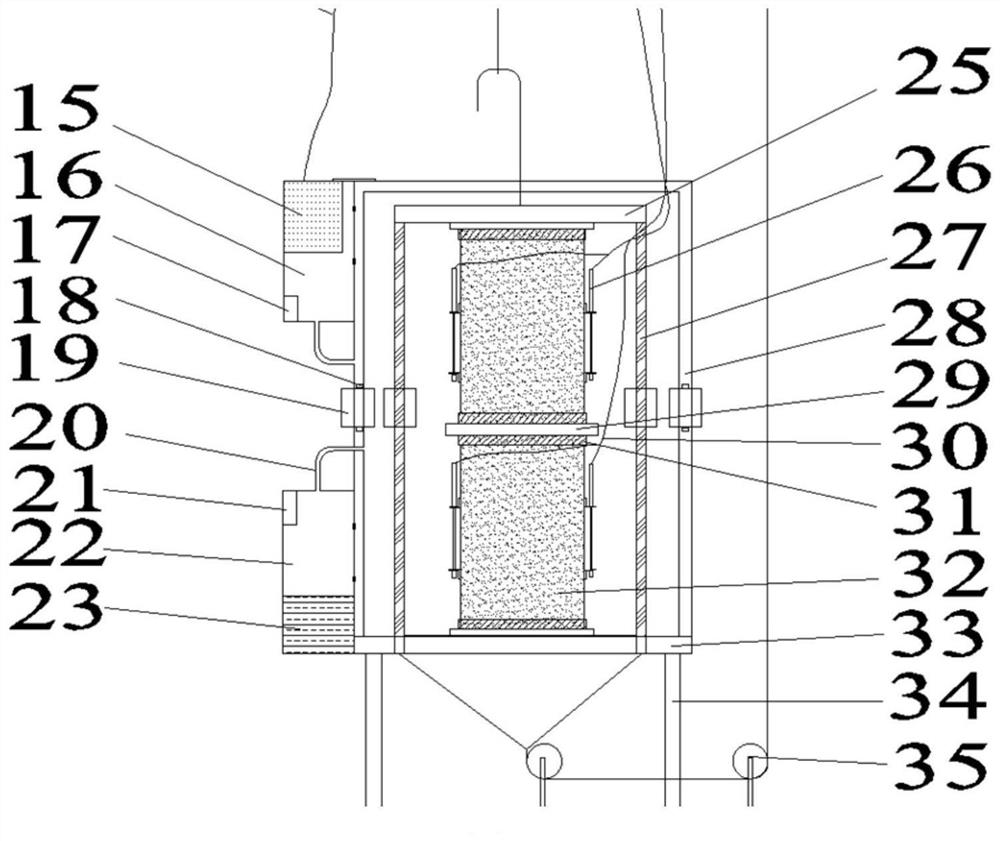

[0030] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described in further detail:

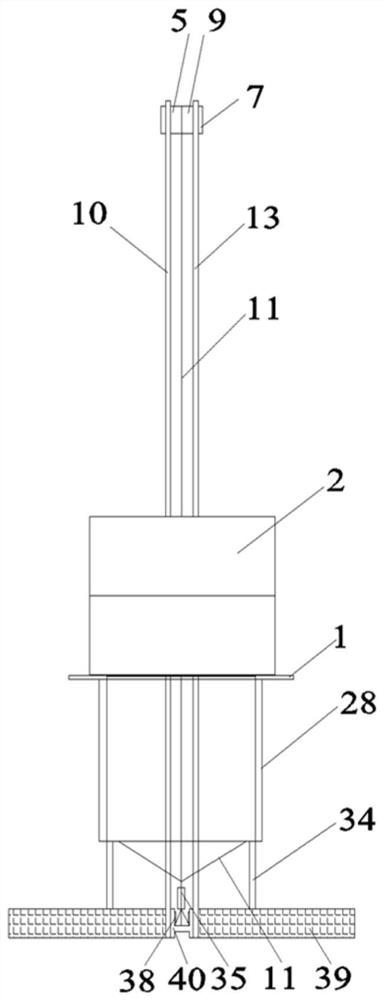

[0031] The water-cement ratio is 0.3, and the hardened cement paste sample with a specification of 20*20*60mm is subjected to an axial pressure creep test for a duration of 30 days after standard curing for 28 days. First fix two LVDTs on the opposite side of the sample and connect the data collector. Set the creep stress to 10MPa. According to the conversion relationship between creep stress and Newton's force, the required pulling force is 4000N, and the pulling force is evenly distributed to load-bearing lever one (5) and load-bearing lever two (9) through the steel strand (11) and the force-bearing coil (8). , which are respectively 2000N, converted into a mass of 204kg. The upper and lower ends of the load-bearing pillar one (10) are respectively connected with the upper connection hole (6) and the lower connection hole (37) in the middl...

specific Embodiment 2

[0034]The water-cement ratio is 0.5, and the hardened cement paste sample with a specification of 30*30*100mm is subjected to an axial pressure creep test for a duration of 30 days after standard curing for 28 days. First fix two LVDTs on the opposite side of the sample and connect the data collector. Set the creep stress to 10MPa. According to the conversion relationship between creep stress and Newton's force, the required pulling force is 9000N, and the pulling force is evenly distributed to load-bearing lever one (5) and load-bearing lever two (9) through the steel strand (11) and the force-bearing coil (8). , which are 4500N respectively, converted into a mass of 460kg. Connect the upper and lower ends of the load-bearing pillar one (10) to the innermost upper connection hole (6) and the lower connection hole (37) respectively. The upper and lower ends of the load-bearing pillar two (13) are respectively connected with the innermost upper connecting hole (6) and the low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Bottom length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com