Production method of seamless stainless steel tube for high-pressure boiler

A technology for stainless steel pipes and production methods, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of inability to increase creep stress and inability to increase the grain size of TP347H stainless steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The production method of the seamless stainless steel tube for the high-pressure boiler of the present embodiment comprises the following production steps:

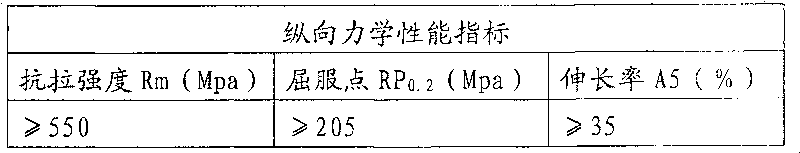

[0023] Adjust the weight ratio of the carbon element contained in the seamless stainless steel raw material of TP347H to 0.06%-0.10%; Solution heat treatment, straightening, cold rolling, degreasing, second solution heat treatment, cold drawing, high temperature creep stress quenching and tempering, straightening and cutting pipes, and pickling.

[0024] Wherein, in the step of high-temperature creep stress conditioning, the seamless stainless steel pipe passes through four sets of conditioning devices successively, and the temperature and linear velocity when passing through each group of conditioning devices are as follows:

[0025] When passing through the first group of quenching and tempering devices, the quenching temperature is 1050°C-1080°C, and the time is 20-30 minutes; the tempering temperature is 680°C-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com