Spray head of steel plate surface-spraying marking device

A marking device and surface spraying technology, applied in printing and other directions, can solve the problem of not being able to effectively prevent the ink from drying out, and achieve the effect of ensuring the quality and safety of the marking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

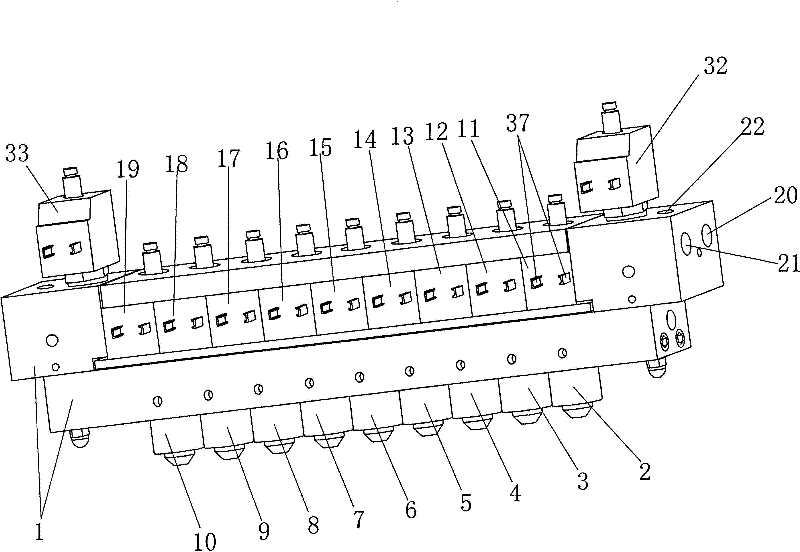

[0018] refer to Figure 1 ~ Figure 2 , the spray head of the surface spray marking device of this steel plate, is characterized by: assembly base 1 and nine nozzles 2, 3, 4, 5, 6, 7, 8, 9, 10 installed on the assembly base 1, nine electromagnetic needles Valves 11, 12, 13, 14, 15, 16, 17, 18, 19, each independent paint liquid passage 20, atomizing air passage 21 and cleaning agent passage 22 arranged in the assembly base 1, each nozzle 2, 3, 4, 5, 6, 7, 8, 9, 10 are respectively controlled by their corresponding electromagnetic needle valves 11, 12, 13, 14, 15, 16, 17, 18, 19, and each nozzle 2 is equipped with Each independent paint solution channel 23, atomizing air channel 24 and cleaning agent channel 25, and the outer ports 26, 27, 28 of each channel 23, 24, 25 are all concentrated on the nozzle 29 of the nozzle 2, and each channel 23, The inner ports of 24 and 25 are respectively connected to the inner ports of the paint liquid channel 20, the atomizing air channel 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com