Film storage device, device and method for producing containers

A storage and item collection technology, applied in thin material handling, transportation and packaging, winding strips, etc., can solve problems such as interference with cutting devices, defects, deviations in running directions, etc., and achieve the effect of large storage volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

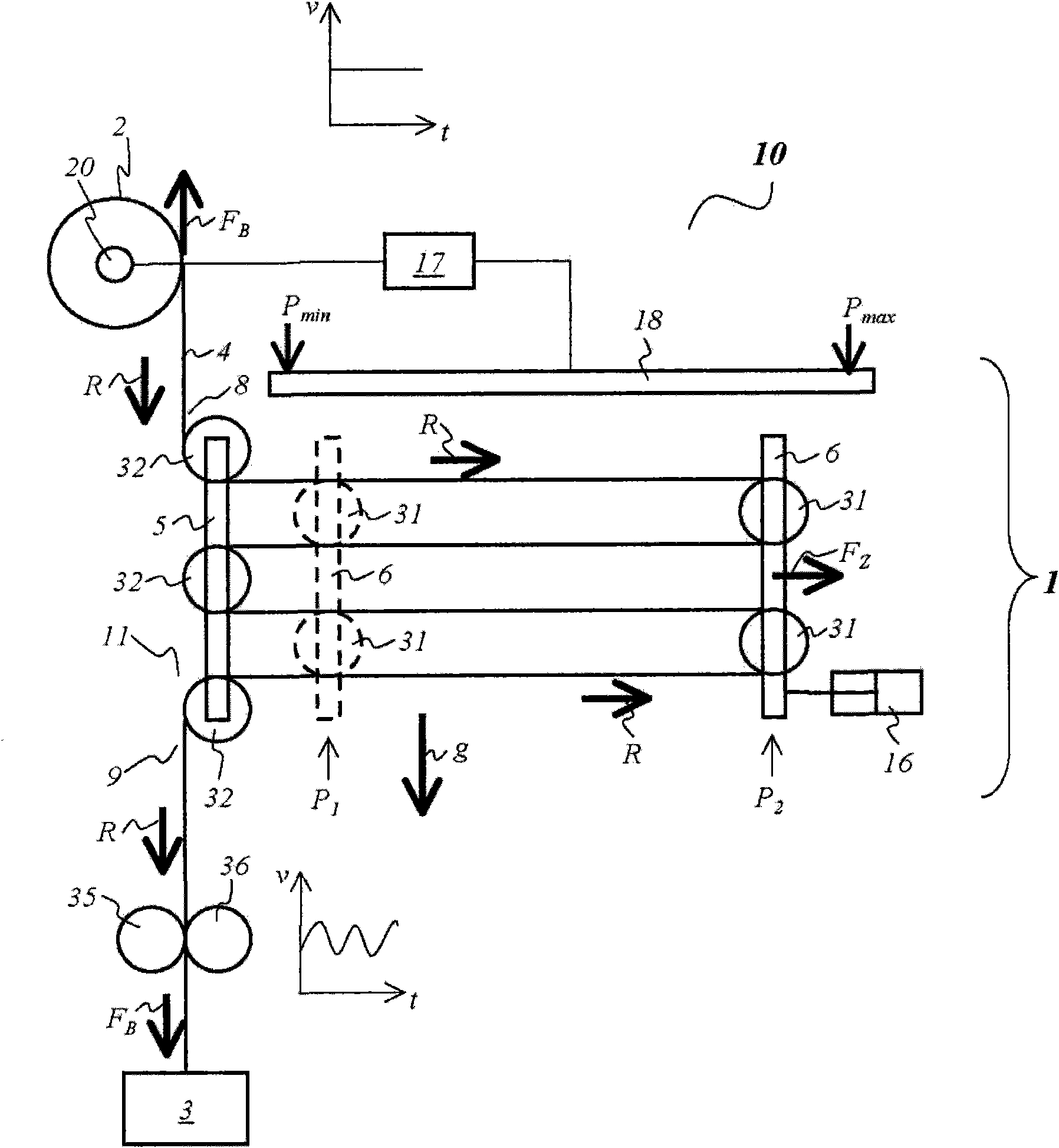

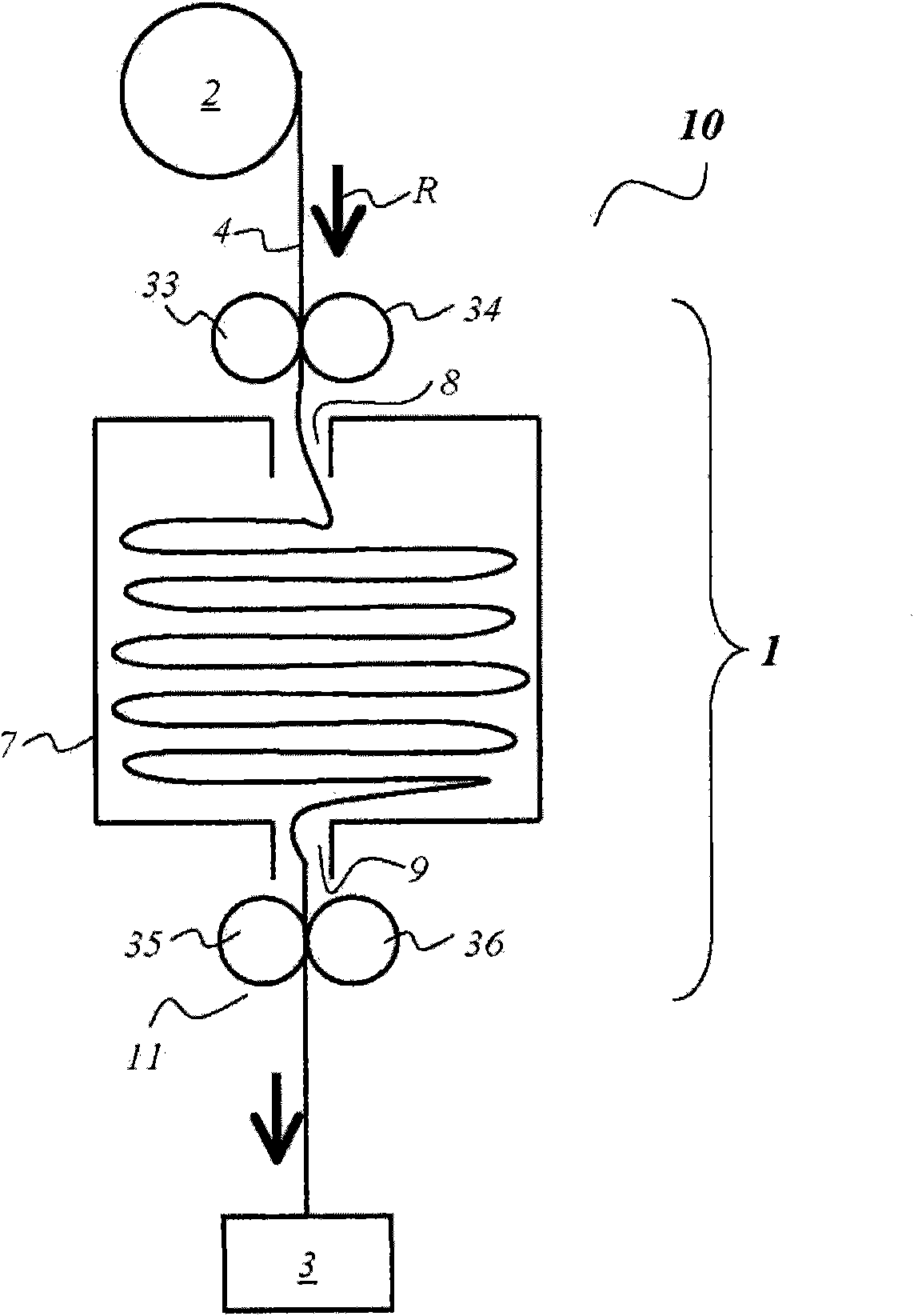

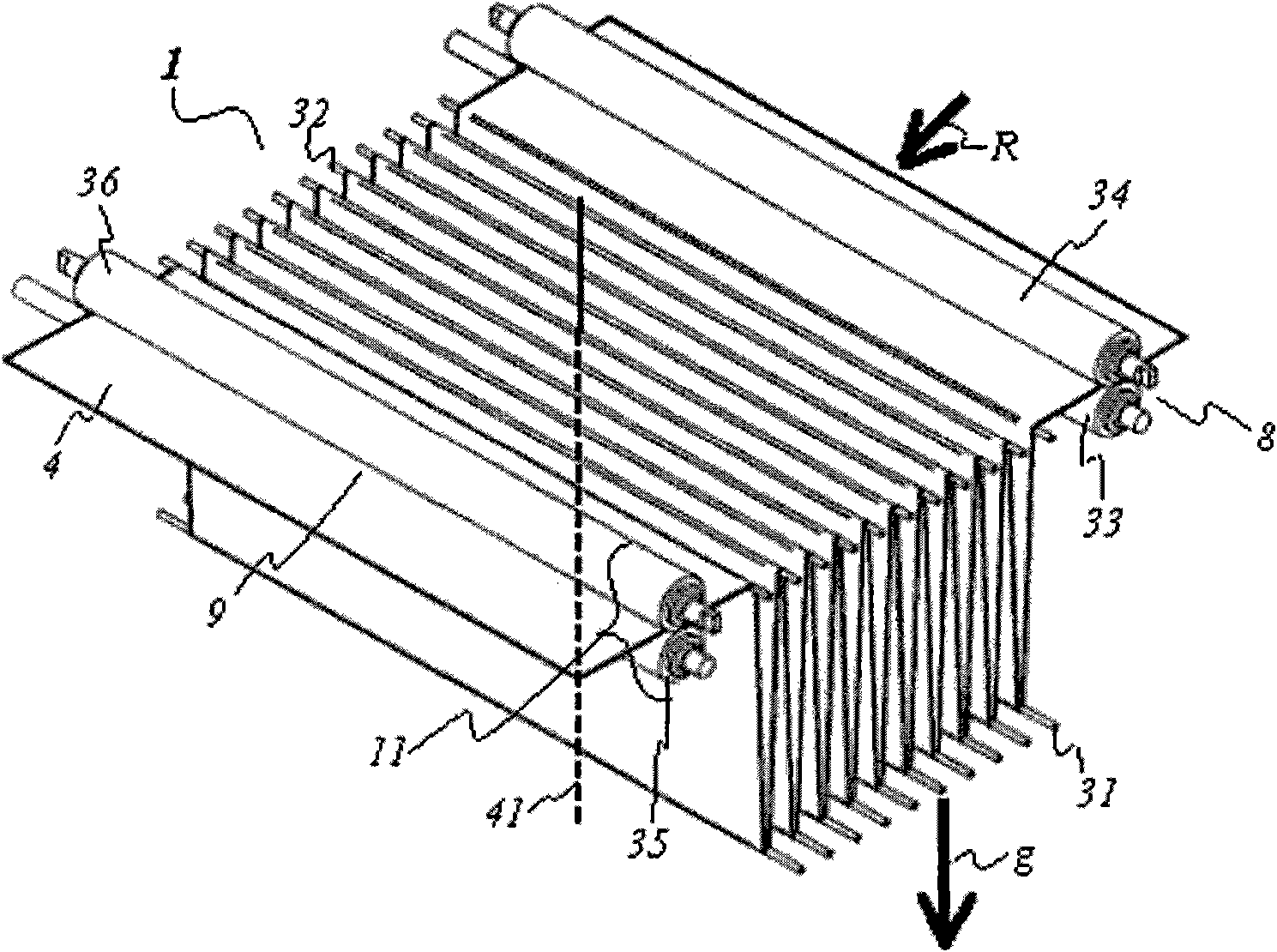

[0049] figure 1 A device 10 for producing a set of objects is shown with an embodiment of a thin-film memory 1 from the prior art. Firstly, the stock holder 2 of the device 10 provides a continuous film 4 in continuous operation. The storage rack 2 is shown in the form of a roll, behind which the film store 1 is arranged in the running direction R of the continuous film 4 . However, the storage carrier 2 can also be designed differently.

[0050] In the running direction R, the continuous film 4 is conveyed on from the storage rack 2 to the film store 1 of the device 10 and is conveyed through the film store 1 of the device 10 and then to the film cutting device 3 of the device 10, which A film cutting device divides the continuous film 4 into individual slices (not shown). Each film slice then winds a respective group of articles into a collection of articles (not shown).

[0051] Reserve holder 2 and film cutting device 3 in figure 1 are only shown very briefly in , s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com