A hydrodynamic cavitation device and system for heavy oil upgrading

A technology for hydrodynamic cavitation and heavy oil upgrading, which is applied in the petroleum industry, refined hydrocarbon oil, etc., can solve the problems of low saturated vapor pressure of heavy oil, high viscosity of heavy oil, high flow velocity, etc. The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

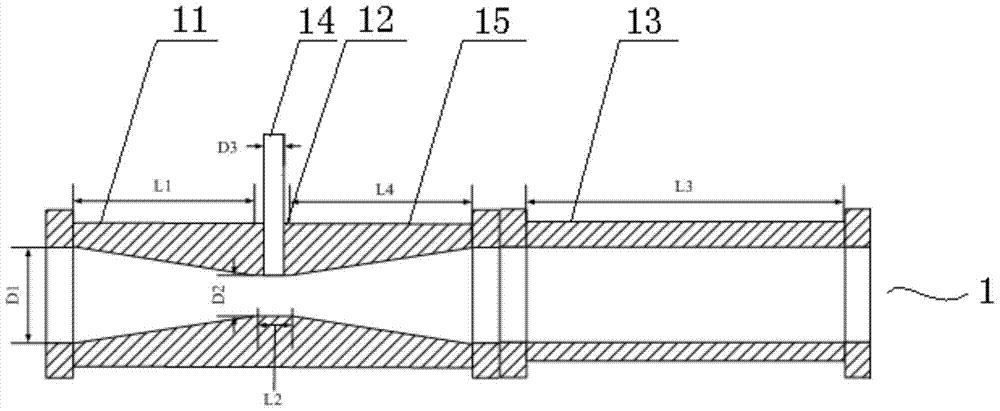

[0031] Such as figure 1 As shown, the hydraulic cavitation device 1 of this embodiment includes a heavy oil inlet section 11, a throat section 12, an expanding section 15 and a stabilizing section 13 arranged in sequence, each section is connected in sequence and communicated axially, and the flow area of the throat section 12 is smaller than The flow area of the inlet end of the heavy oil inlet section 11 and the outlet end of the enlarged section 15, the heavy oil inlet section 11 and the enlarged section 15 have trumpet-shaped through holes, and the small ends of the trumpet-shaped through holes are all set toward the throat section 12, and on the throat section 12 An auxiliary agent inlet section 14 communicating with the throat section 12 is arranged radially.

[0032] Specifically, the heavy oil inlet section 11, the throat section 12, and the expansion section 15 can be integrally formed, and the throat section 12 and the expansion section 15 are both cylindrical an...

Embodiment 2

[0038] Adopt the hydraulic cavitation device of embodiment 1 to carry out heavy oil reforming, difference is: D1 is 40mm, D2 / D1 is 0.3, D3 / D2 is 0.4, L1 / D1 is 2, L2 / D2 is 1, L3 / D1 is 5. L4 / D1 is 2, the inner diameter of the inlet end of the stabilizing section and the outlet end of the expanding section are both 40mm, and the heavy oil inlet section, throat section, expanding section and stabilizing section are integrally formed.

[0039] After the heavy oil is heated to about 50°C and pressurized to about 4MPa by a high-pressure pump, it is sent to the heavy oil inlet section of the hydraulic cavitation device. When the heavy oil reaches the throat section, dimethyl disulfide is sucked into the hydraulic air chamber through the auxiliary agent inlet section. In the gasification device, dimethyl disulfide is vaporized, and heavy oil and dimethyl disulfide undergo hydrodynamic cavitation, wherein, the addition amount of dimethyl disulfide is controlled so that the weight ratio o...

Embodiment 3

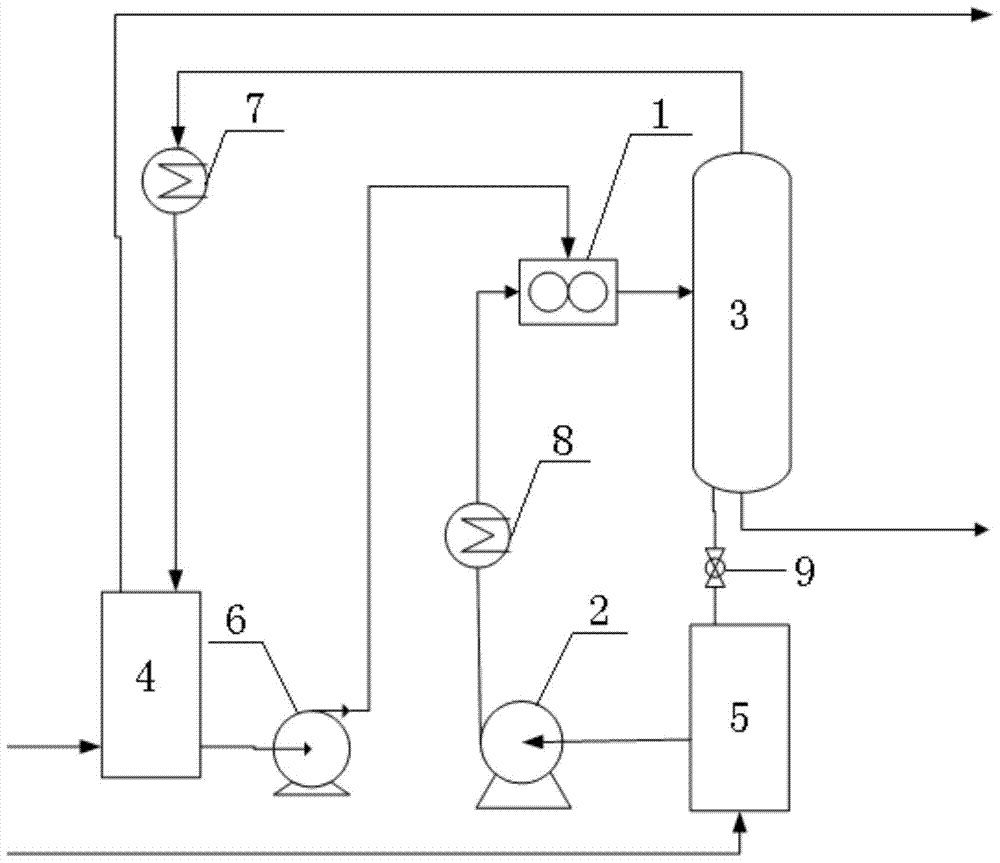

[0048] Such as figure 2 As shown, the hydraulic cavitation system for heavy oil upgrading in this embodiment includes a hydraulic cavitation device 1, a high-pressure pump 2 and a gas-liquid separation device 3, the high-pressure pump 2 is connected to the heavy oil inlet section of the hydraulic cavitation device 1, and the gas The liquid separation device 3 is connected with the stabilization section of the hydraulic cavitation device 1 . Specifically, the hydraulic cavitation device 1 may be the hydraulic cavitation device of Embodiment 1 or 2.

[0049] Further, the system also includes an auxiliary cavitation agent storage tank 4 and a heavy oil storage tank 5, the auxiliary cavitation agent storage tank 4 is connected to the auxiliary agent inlet section of the hydraulic cavitation device 1 through a pipeline, and the heavy oil storage tank 5 is connected to the high-pressure Pump 2 is connected. Moreover, a pump 6 may be provided on the pipeline between the auxiliary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com