Method for preparing phosphaphenanthrene and phosphazene halogen-free retardant agent

A technology of miscellaneous phenanthrene phosphazene and flame retardant, which is applied in the field of preparation of phosphorus-nitrogen additive flame retardants, can solve problems such as non-existence, and achieve high yield, high preparation efficiency, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

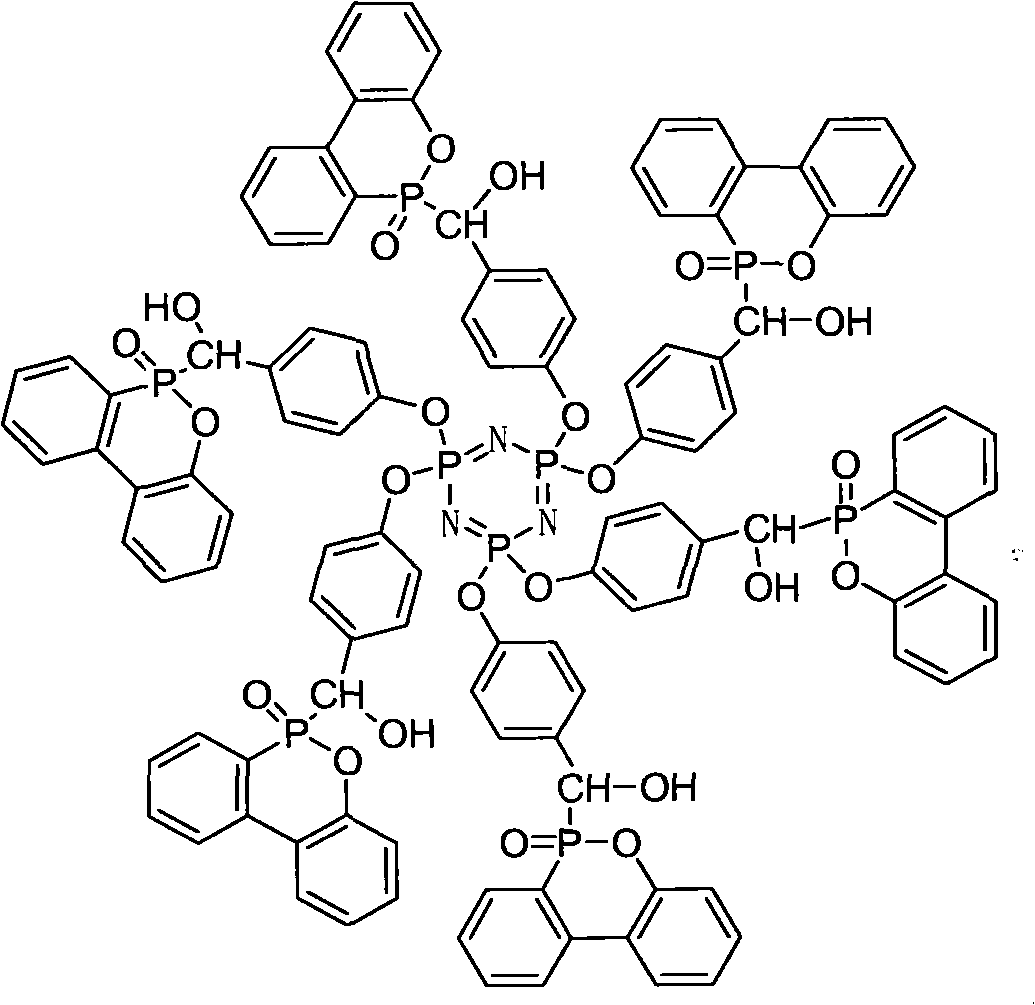

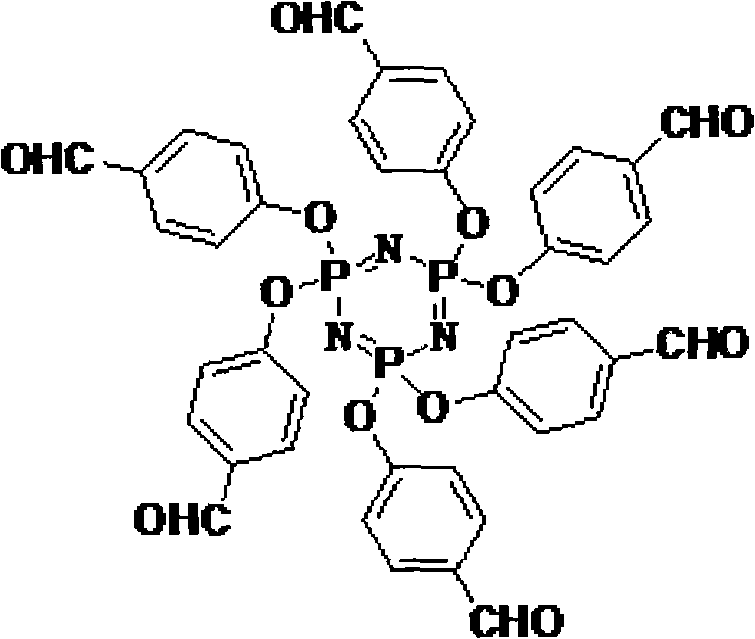

Embodiment 1

[0015] Example 1 Heat 18g of DOPO to 130°C, add 4g of hexa(4-formyl-phenoxy)-cyclotriphosphazene, and melt for 10 hours; after the reaction is completed, cool down to 120°C, and add 12g of xylene as a washing solvent while stirring , the holding temperature is 100°C, stirred for 3 hours, filtered the white powder with a Buchner funnel, added the same amount of xylene and washed it repeatedly for 3 times, after the white powder was obtained, it was dried at 80°C, and the final product hexa-(phosphora The phenanthrene-hydroxymethyl-phenoxy)-cyclotriphosphazene powder was 11.88g, the yield was 99.0%, and the purity was 99.2%.

Embodiment 2

[0016] Example 2 Heat 12g of DOPO to 160°C, add 4g of hexa(4-formyl-phenoxy)-cyclotriphosphazene, and melt for 5 hours; after the reaction is completed, cool down to 100°C, and add 24g of toluene as a washing solvent while stirring, The heat preservation temperature was 100°C, stirred for 3 hours, filtered the white powder with a Buchner funnel, repeated washing 4 times, after the white powder was obtained, dried at 80°C, and the final product hexa-(phosphaphenanthrene-hydroxymethyl-benzene Oxygen)-cyclotriphosphazene was 11.82 g of powder, with a yield of 98.5% and a purity of 99.1%.

Embodiment 3

[0017] Example 3 Heat 180g of DOPO to 160°C, add 40g of hexa(4-formyl-phenoxy)-cyclotriphosphazene, and melt for 12 hours; after the reaction is completed, cool down to 130°C, and add 180g of chlorobenzene as a washing solvent while stirring , the holding temperature was 110°C, stirred for 1 hour, filtered the white powder with a Buchner funnel, repeated washing 3 times in the same way, after the white powder was obtained, dried at 80°C, and the final product hexa-(phosphaphenanthrene-hydroxyl Methyl-phenoxy)-cyclotriphosphazene was 119.04 g of powder, with a yield of 99.2% and a purity of 99.3%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap