Turbine housing with wall cladding

A technology for turbine casings and baseboards, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of unsealed joint area, uneven temperature distribution stress, uneven wall thickness of shell parts, etc. Achieving reduced temperature gradients, easy availability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

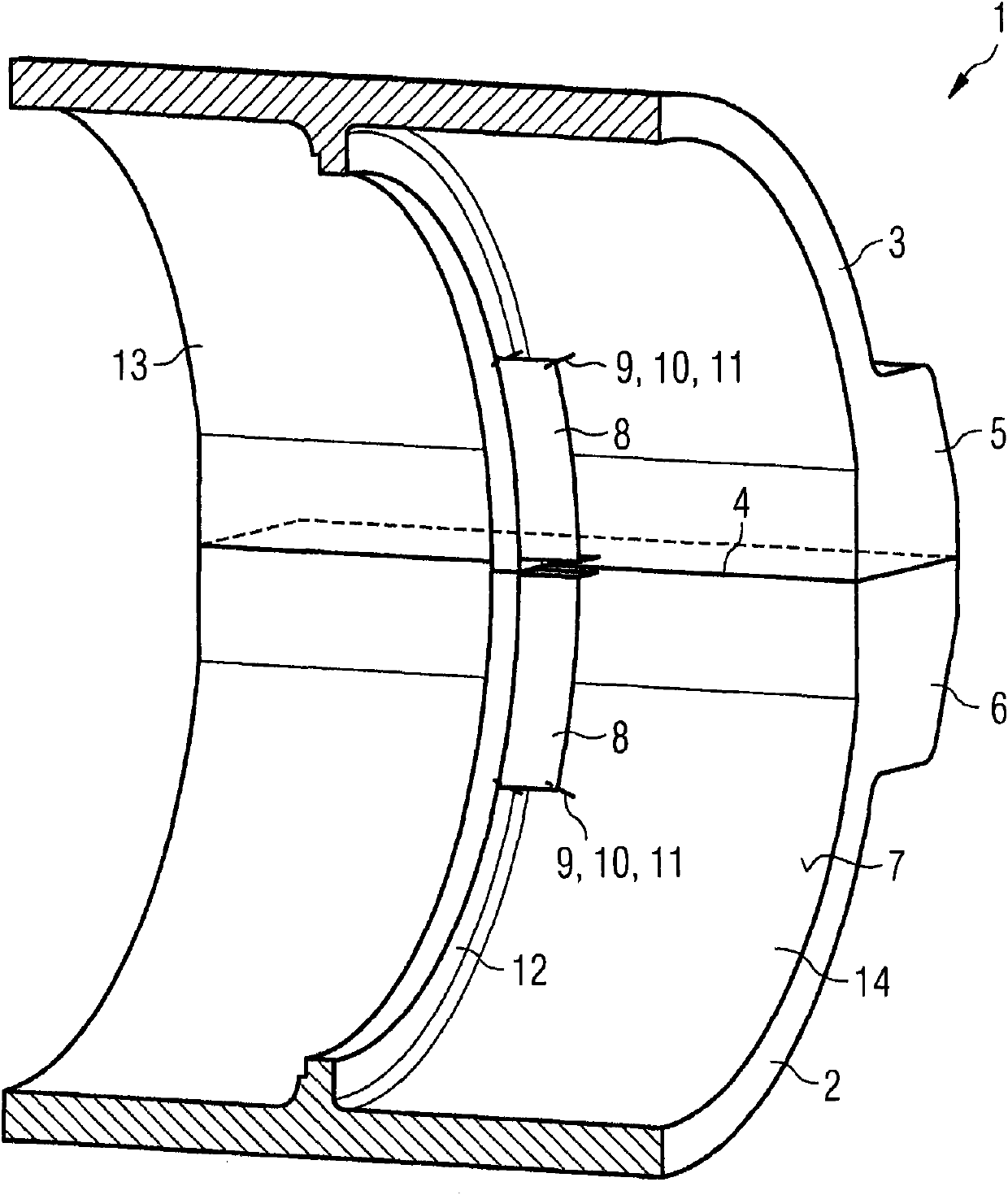

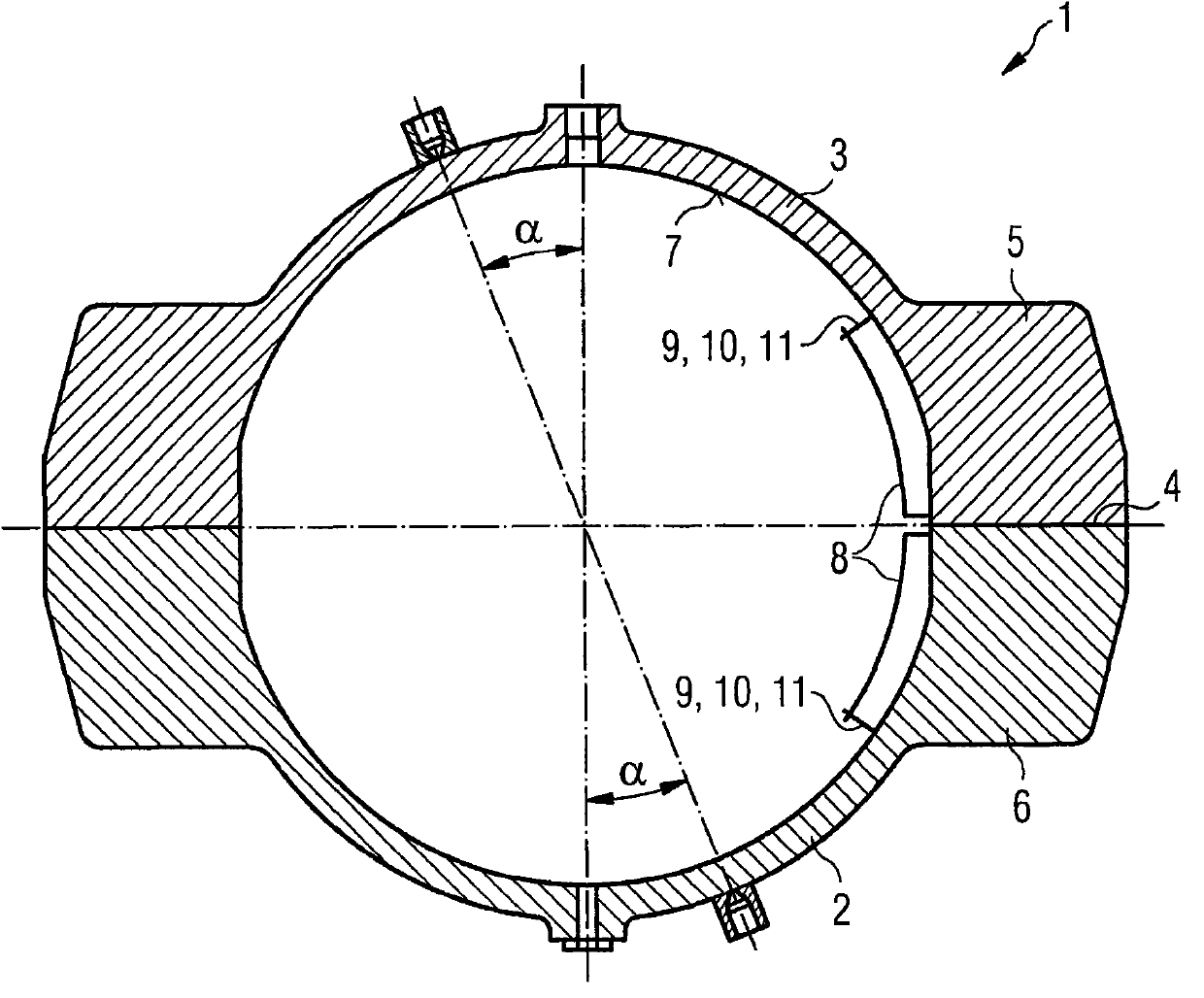

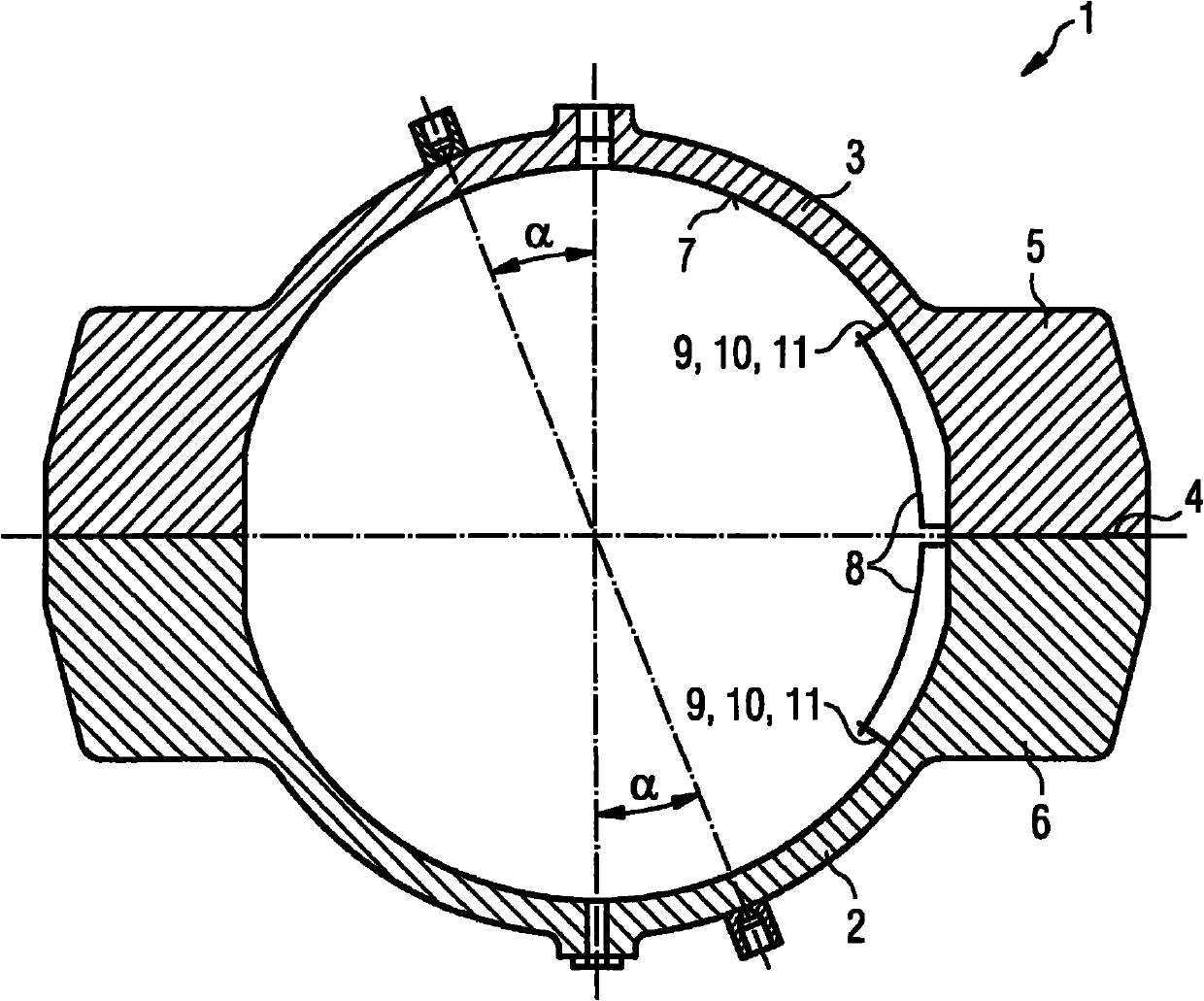

[0019] figure 1 A three-dimensional sectional view of a turbine housing according to the invention is shown. The turbine housing 1 comprises a turbine housing lower part 2 and a turbine housing upper part 3 . The two turbine housing parts 2 , 3 engage with each other in the assembled state. In this case, the joints 4 are respectively formed on the joint surfaces. In order that fluid cannot flow from the inside of the turbine housing 1 to the outside, the joint 4 must be closed as tightly as possible. For this purpose, the lower part 2 of the turbine housing and the upper part 3 of the turbine housing are firmly screwed together. For a good screwing of the two turbine housings 2 and 3 , the two turbine housing parts each have a joining flange 5 , 6 . Engagement bolt 11 (in figure 1 (not visible in ) are arranged in the joint flanges 5,6. The turbine housing 1 is sealed by screwing the two turbine housing parts 2 , 3 . On the inner side of the outer housing, webs 12 for r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com