Backlight module

A backlight module and backplane technology, which is applied in the direction of electric light source, light source fixing, and damage prevention measures for lighting devices, etc., can solve the problems of reducing the optical performance of the backlight module, prone to scratches, limited effect, etc., and achieve the goal of improving the optical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

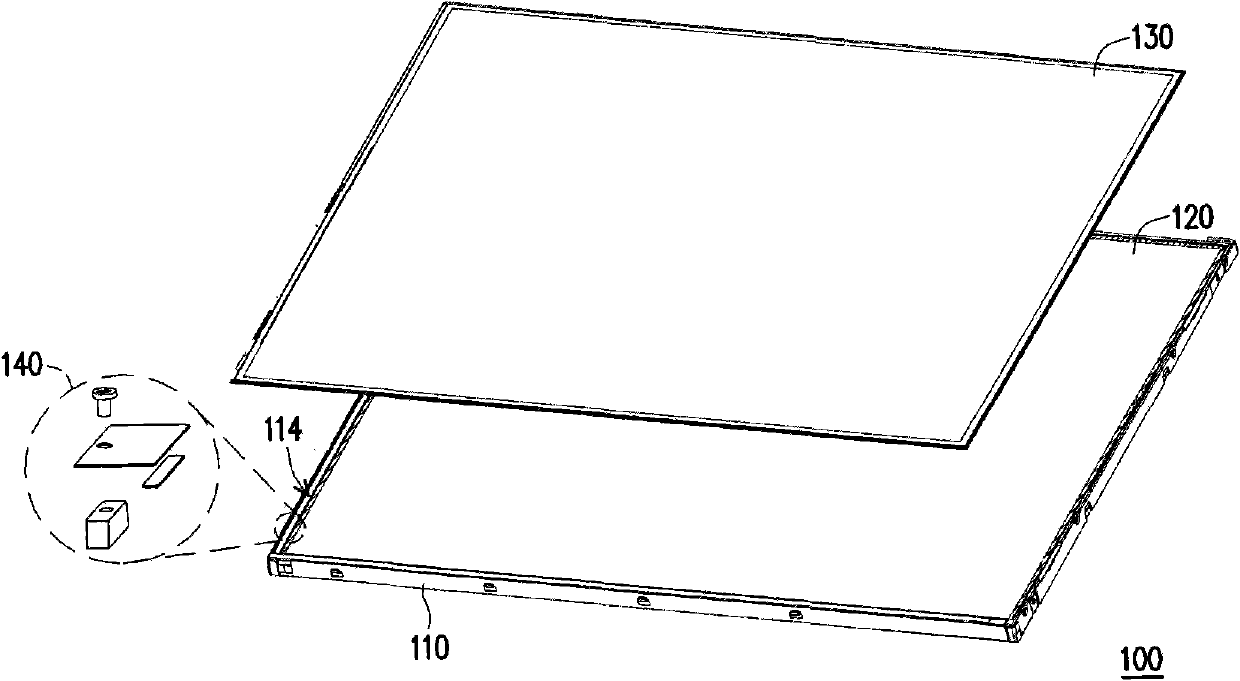

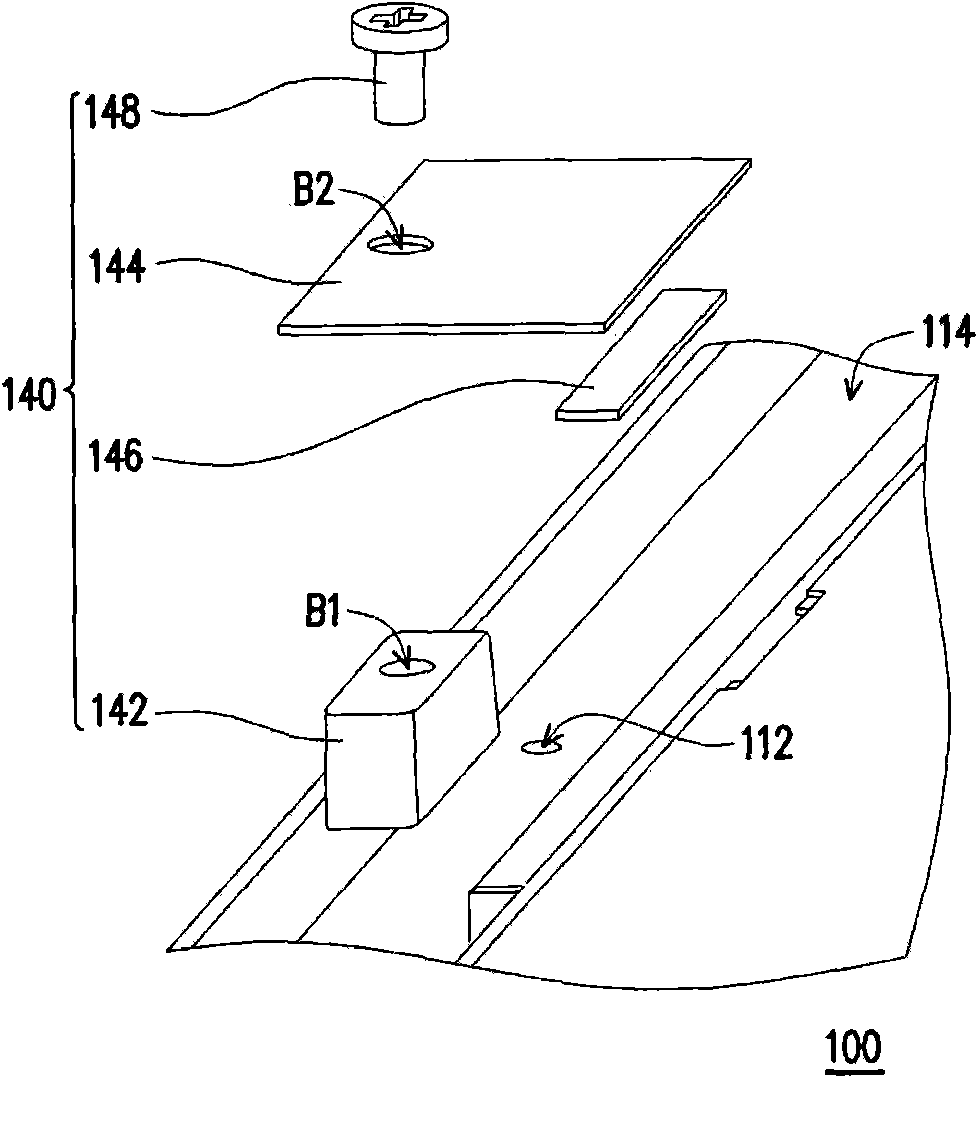

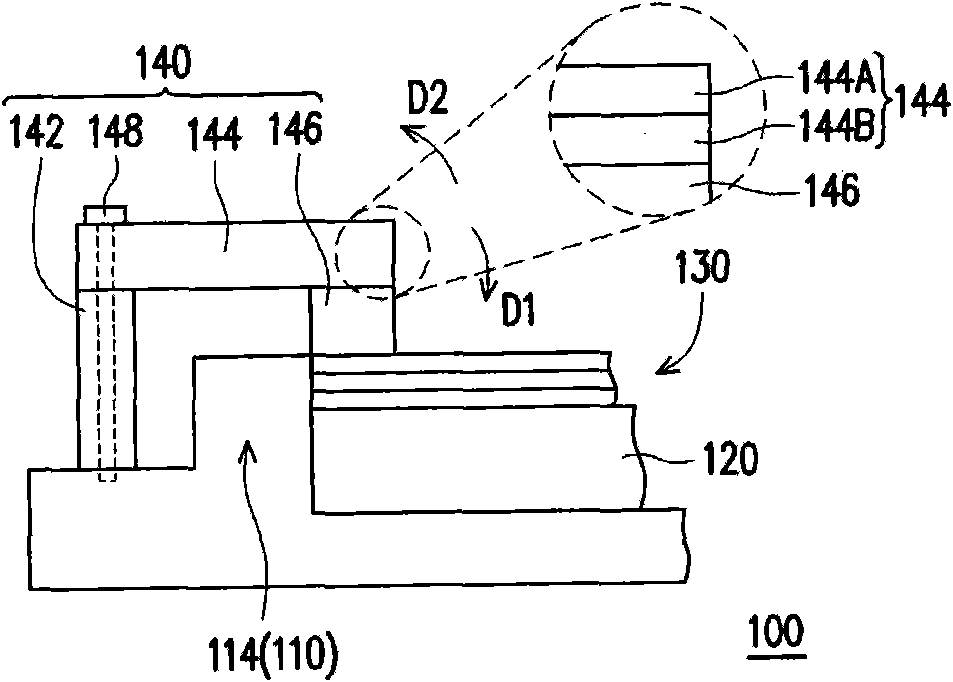

[0057] Figure 1A It is an exploded view of a backlight module according to an embodiment of the present invention. Figure 1B yes Figure 1A A partial enlargement of the . Figure 1C yes Figure 1B The cross-sectional view of the assembled backlight module, in which some components are asymmetrically enlarged to clearly identify the relevant components. Please also refer to Figure 1A to Figure 1C , in this embodiment, the backlight module 100 includes a backplane 110 , a light guide plate 120 , a plurality of optical films 130 and a clamping device 140 . The light guide plate 120 is disposed in the area surrounded by the edge structure 114 of the backplane 110, and the backplane 110 can be made of metal or plastic. The optical film 130 is disposed on the light guide plate 120 . The clamping device 140 includes a support piece 142 , a clamping piece 144 and a buffer piece 146 . The supporting member 142 protrudes from the backplane 110 and may be a metal bump or a plasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com