Optical device and method of manufacturing the same

A technology of an optical device and a manufacturing method, applied in the directions of optics, optical components, installation, etc., can solve the problem of unimproved fluctuation of a lens accommodating portion, and achieve the effects of minimizing the reduction of throughput and suppressing fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

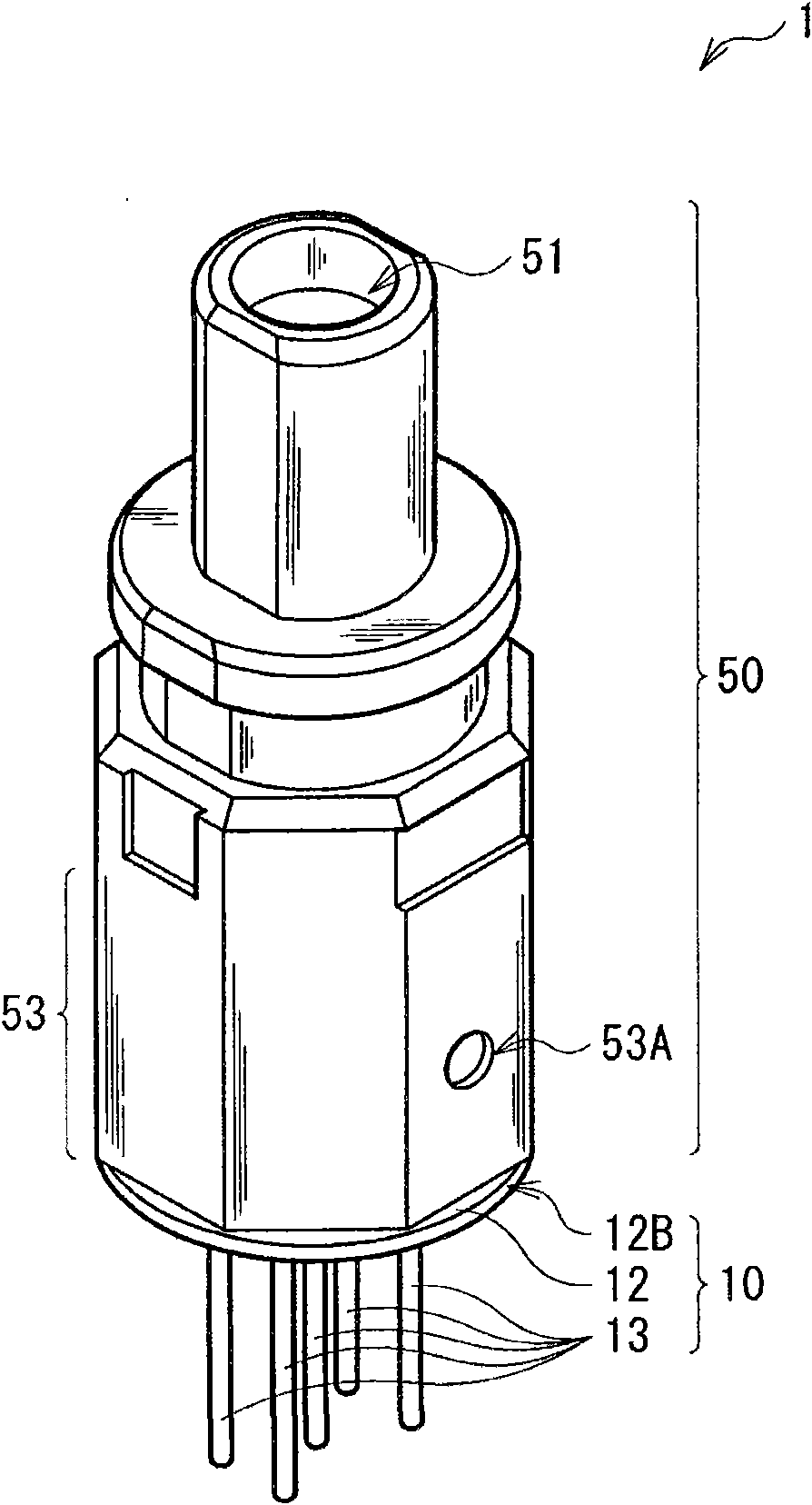

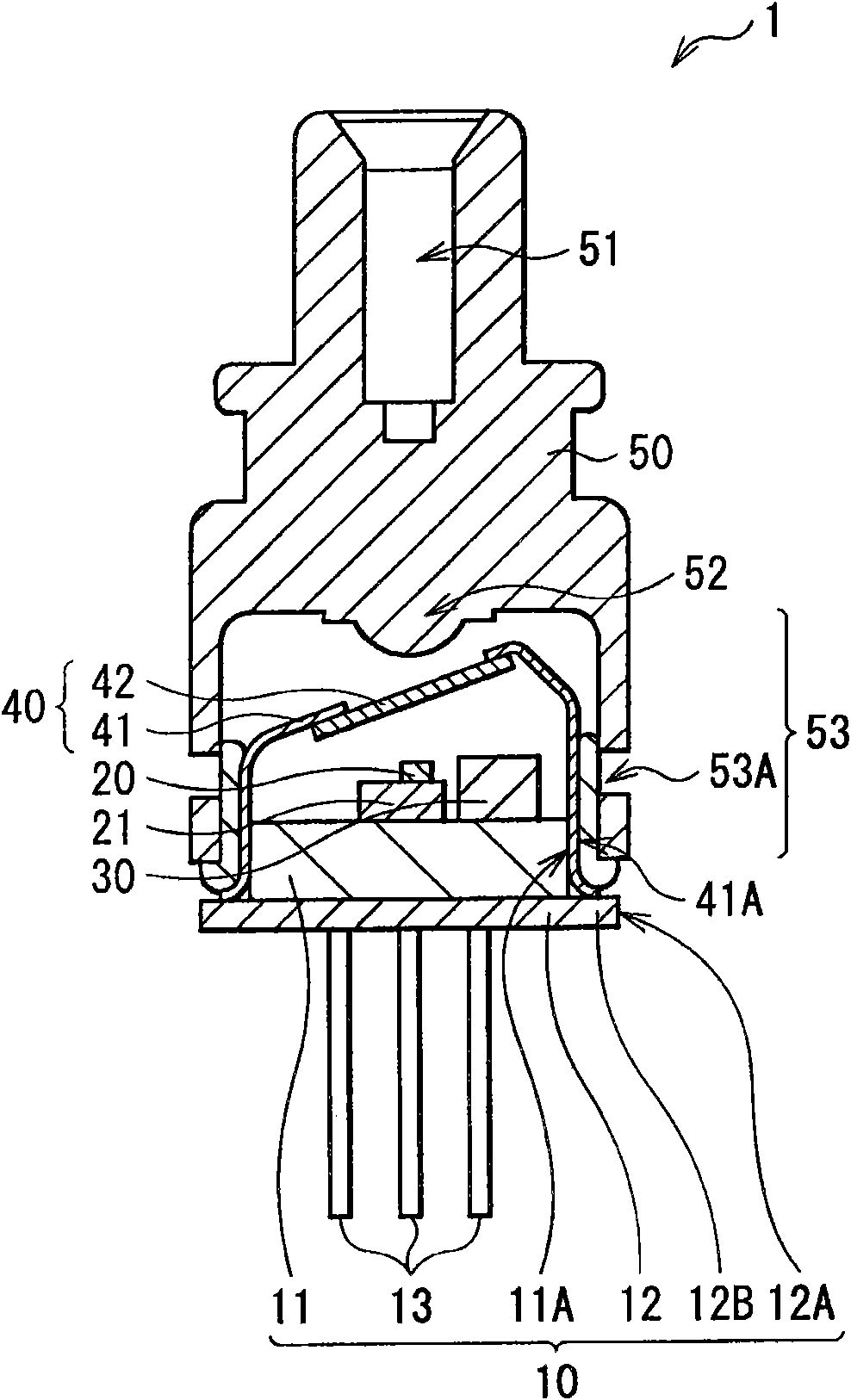

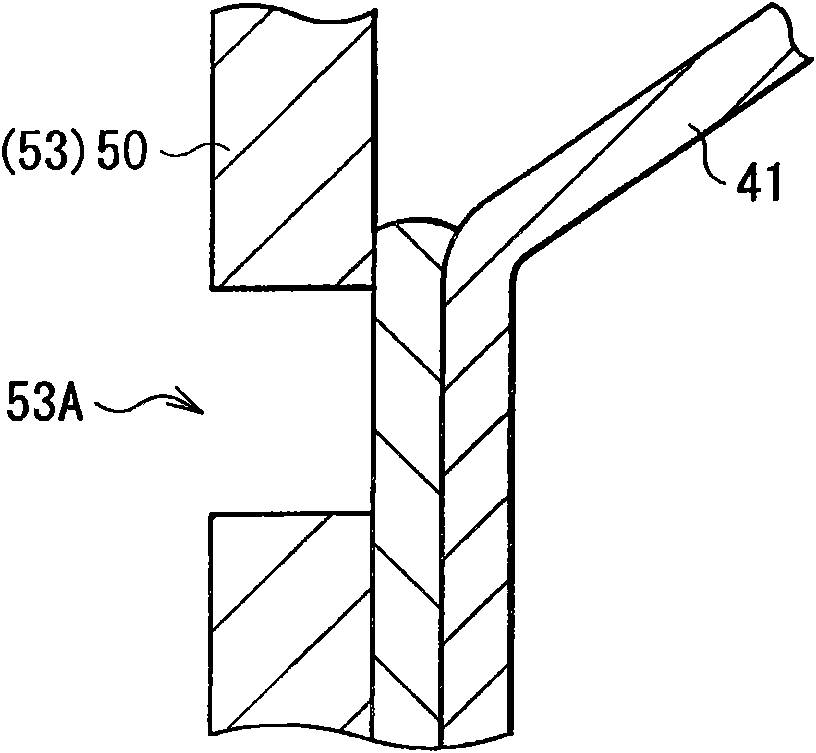

[0031] figure 1 It is a perspective view of a schematic structure of a light transmitter device (light transmitter device) 1 according to an embodiment of the present invention. figure 2 show figure 1 The cross-sectional structure of the optical transmitter. figure 1 and 2 are schematically shown configurations, and may differ from actual sizes or shapes.

[0032] The optical transmission device 1 of this embodiment is generally called TOSA (Transmitter Optical Sub Assembly, optical transmission sub-assembly), which converts an externally input electrical signal into an optical signal and outputs the optical signal. The light transmitting device 1 includes, for example, a stem 10 , a light emitting element 20 , a light receiving element 30 , a cap 40 and a lens housing 50 . The stem portion 10 corresponds to a specific example of the "bas...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap