Secondary encapsulated waterproof process and structure of liquid crystal display (LCD) face frame

A waterproof structure and secondary packaging technology, which is applied in optics, instruments, nonlinear optics, etc., can solve the problems of labor-consuming and time-consuming installation of operators, increased production costs, high cost of large touch screens, etc., and achieve a good waterproof effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

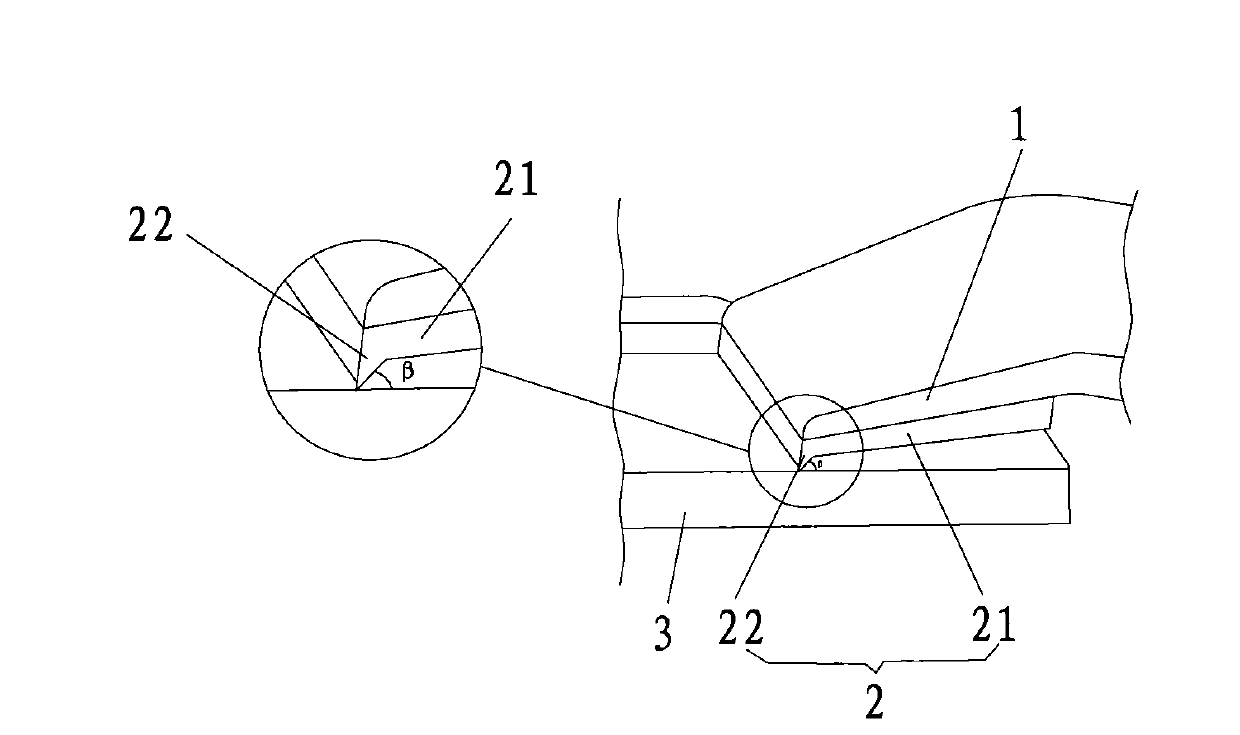

[0025] Example: see Figure 3 to Figure 7 , a secondary glue-coated waterproof structure for an LCD surface frame, comprising a plastic shell surface frame 1 and a waterproof plastic inner frame 2 integrated with it by injection molding, and the waterproof plastic inner frame 2 is distributed along the annular inner edge of the plastic shell surface frame 1 and combined as a whole , and the waterproof plastic inner frame extends toward the touch screen 3 in the LCD frame and touches against the surface of the touch screen to form a waterproof structure.

[0026] see image 3 , the waterproof plastic inner frame 2 is composed of a plastic main body 21 and a composite plastic waterproof end 22. The plastic waterproof end 22 is a sharp corner formed by the extension of the plastic main body 21 to the touch screen, and the contact angle β with the touch screen is Between 50±10°, the thickness of the plastic body of the waterproof plastic inner frame is 1.5±0.2mm.

[0027] see ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap