Coaxial plug and manufacture method thereof

A technology of a coaxial plug and a manufacturing method, which is applied to the field of coaxial plugs and their manufacturing, can solve the problems of increasing defective products, shifting the injection position, increasing the difficulty of manufacturing, etc., so as to increase the injection space, facilitate the injection, and reduce the defects. The effect of the probability of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

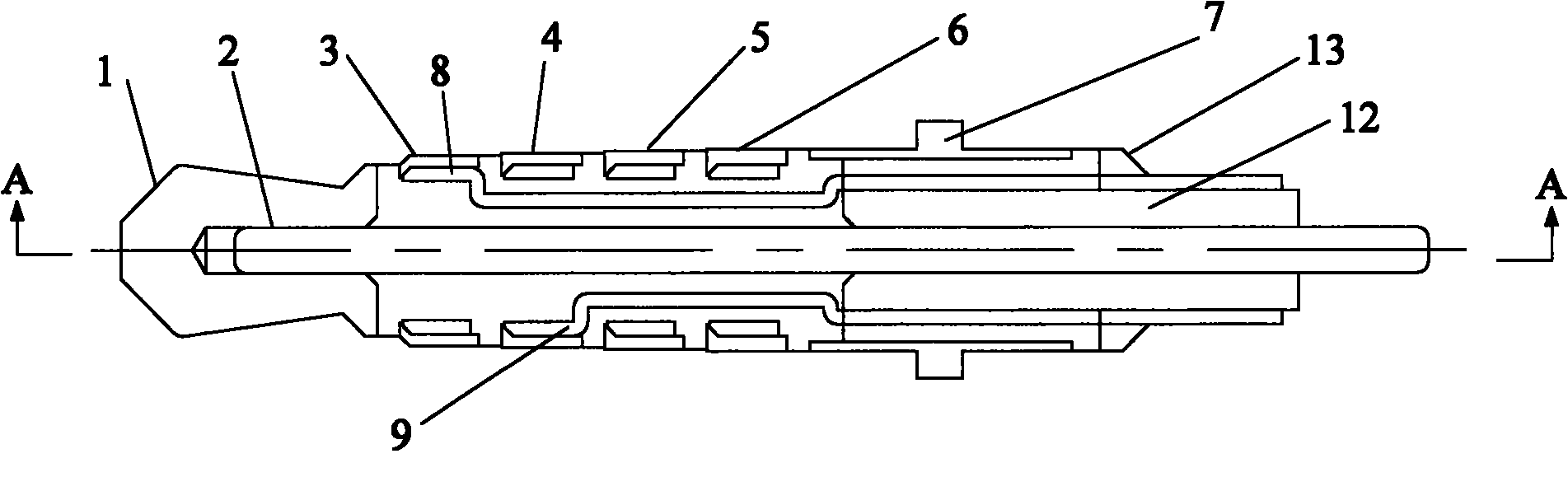

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0037] The coaxial plug of the present invention mainly includes an electrode head, a central column and at least two coaxial annular electrodes distributed in a stepwise manner, and the coaxial annular electrodes are separated from each other by a coaxial annular insulator.

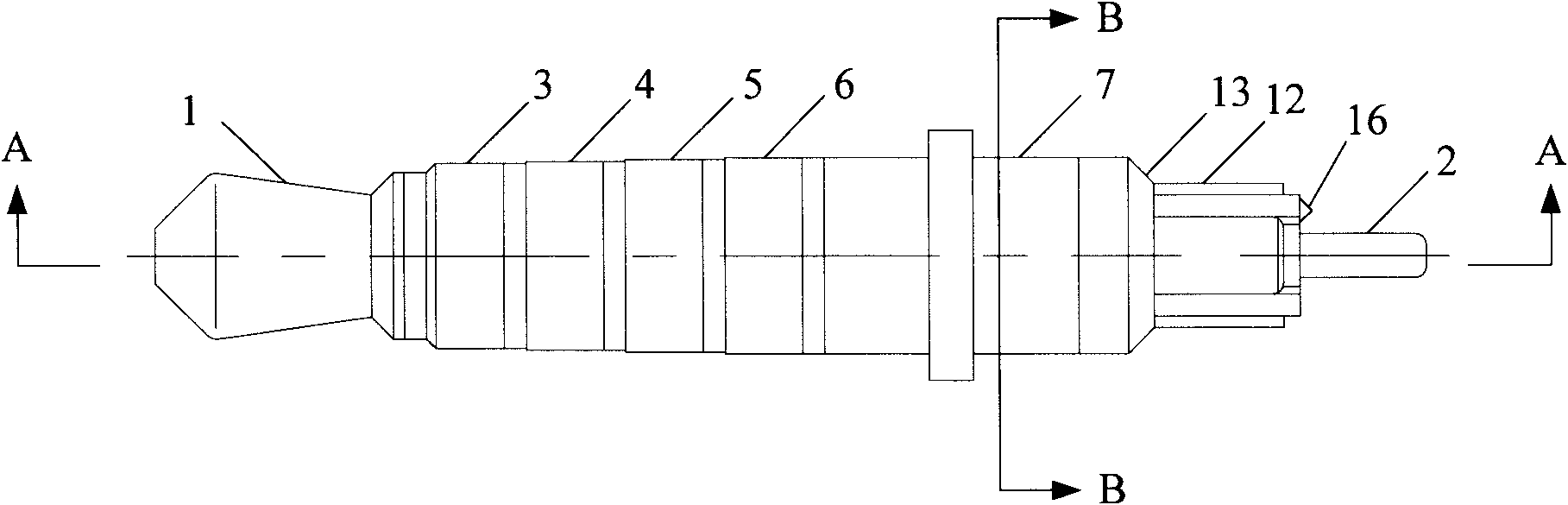

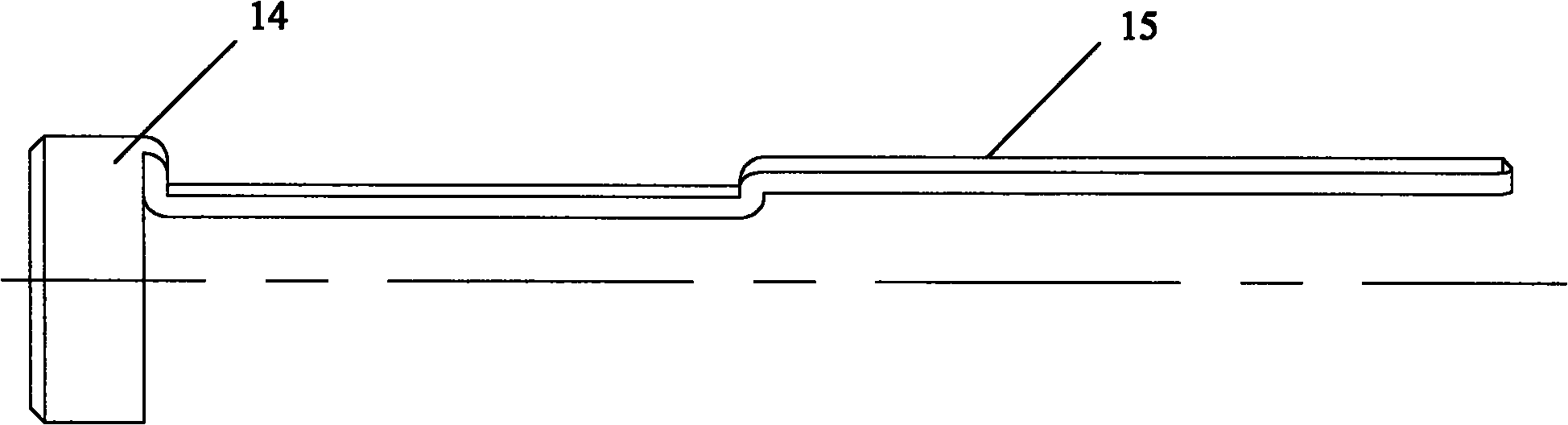

[0038] Such as figure 1 , figure 2 As shown, the plug part of the coaxial plug includes an electrode head 1 and a central column 2, and the coaxial annular electrode includes an electrode ring and an electrode ring conductor, wherein there are five electrode rings, such as figure 1 As shown in 3-7, the first four electrode rings are distributed in steps, that is, the diameters of the electrode rings increase sequentially, and the diameter of the terminal electrode ring 7 is the same as that of the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com