Part feeder for chip mounting device

A chip mounting and feeder technology, applied in the direction of electrical components, electrical components, etc., to achieve the effect of preventing wrong mounting, and quick and easy mounting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, one embodiment of the present invention will be described with appropriate reference to the drawings.

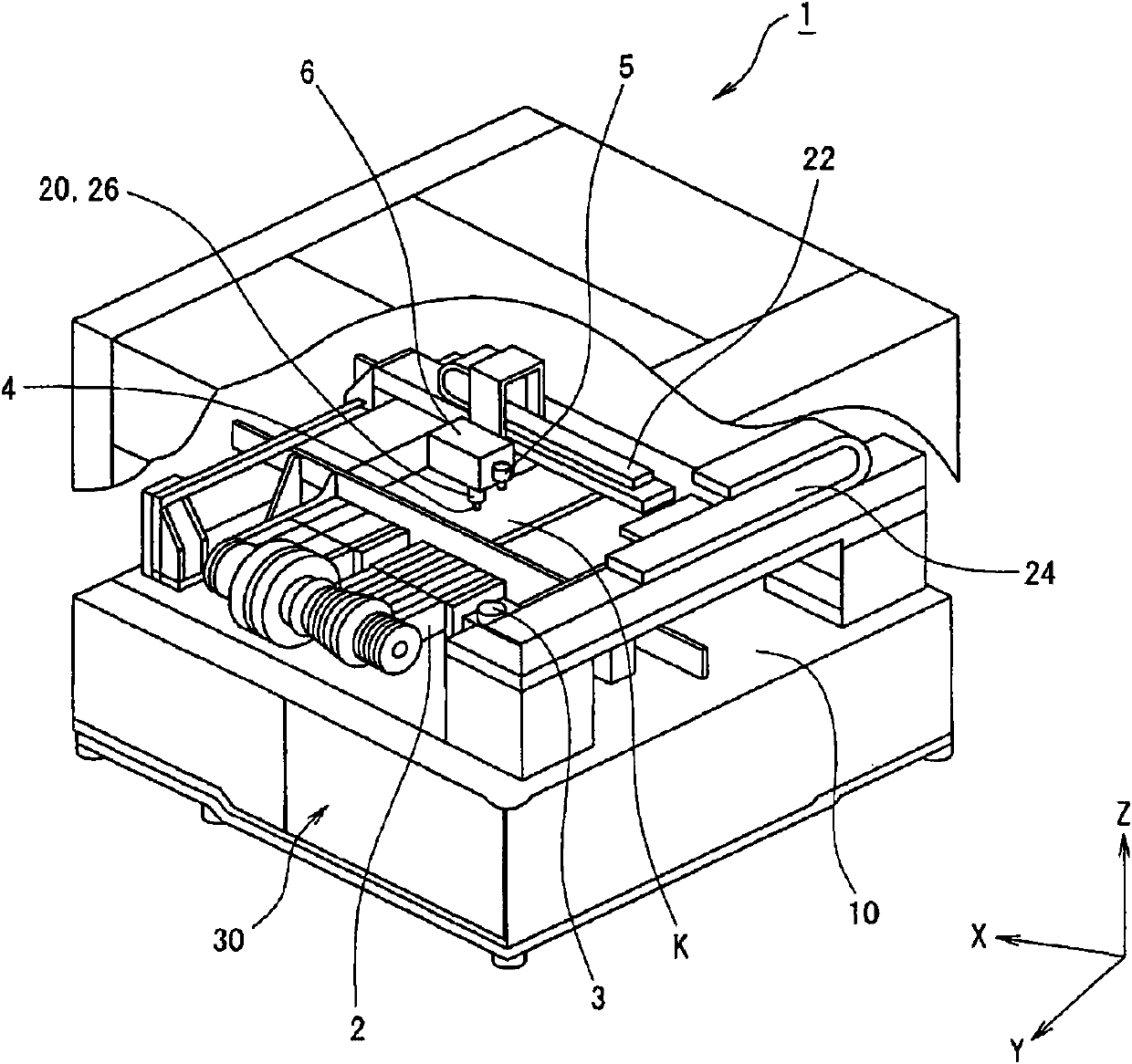

[0022] Such as figure 1 As shown, the chip mounting apparatus 1 is provided with a component feeder 2 and a component recognition camera 3 as a plurality (for example, 60) of electric component supply devices for supplying electronic components (not shown) on the lower side of the figure. In addition, a substrate transfer device 10 for carrying in and carrying out the substrate K extends in the left-right direction at a substantially central portion in the drawing, and the substrate K is placed on the substrate transfer device 10 . In addition, the component mounting head 6 is disposed above the substrate transfer device 10 . The component mounting head 6 is provided with a suction nozzle 4 for suctioning mounted electronic components, and a substrate recognition camera 5 capable of photographing substrate marks and electronic components on the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com