Working roll for automobile sheet cold rolling and manufacturing method thereof

A technology of cold-rolled work rolls and manufacturing methods, which is applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve problems affecting the quality of the board surface, etc., achieve the effects of improving anti-accident performance, realizing localization, and increasing the strength of the matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The manufacturing method of the cold-rolled work roll of the present embodiment comprises the following steps:

[0028] ① Refining steel to make the chemical composition and content of the steel reach the required range, and use related production processes to make cold-rolled billets. The specific steps are as follows: when refining steel, use electric arc furnace and LF / VD refining furnace to smelt, die cast into electrodes, then anneal the electrode rods, and then use electroslag remelting to make electroslag ingots.

[0029] Through final assay, the chemical composition and percentage composition of the present embodiment electroslag ingot are as follows:

[0030] C

Si

mn

Cr

Mo

V

Ni

P

S

0.85

0.95

0.26

4.89

0.33

0.03

0.16

0.017

0.003

[0031] The rest is Fe and unavoidable impurities. After the composition is qualified, the electroslag ingot is heated, forged into a...

Embodiment 2~ Embodiment 8

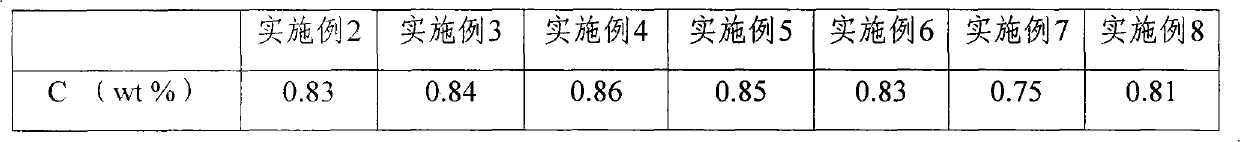

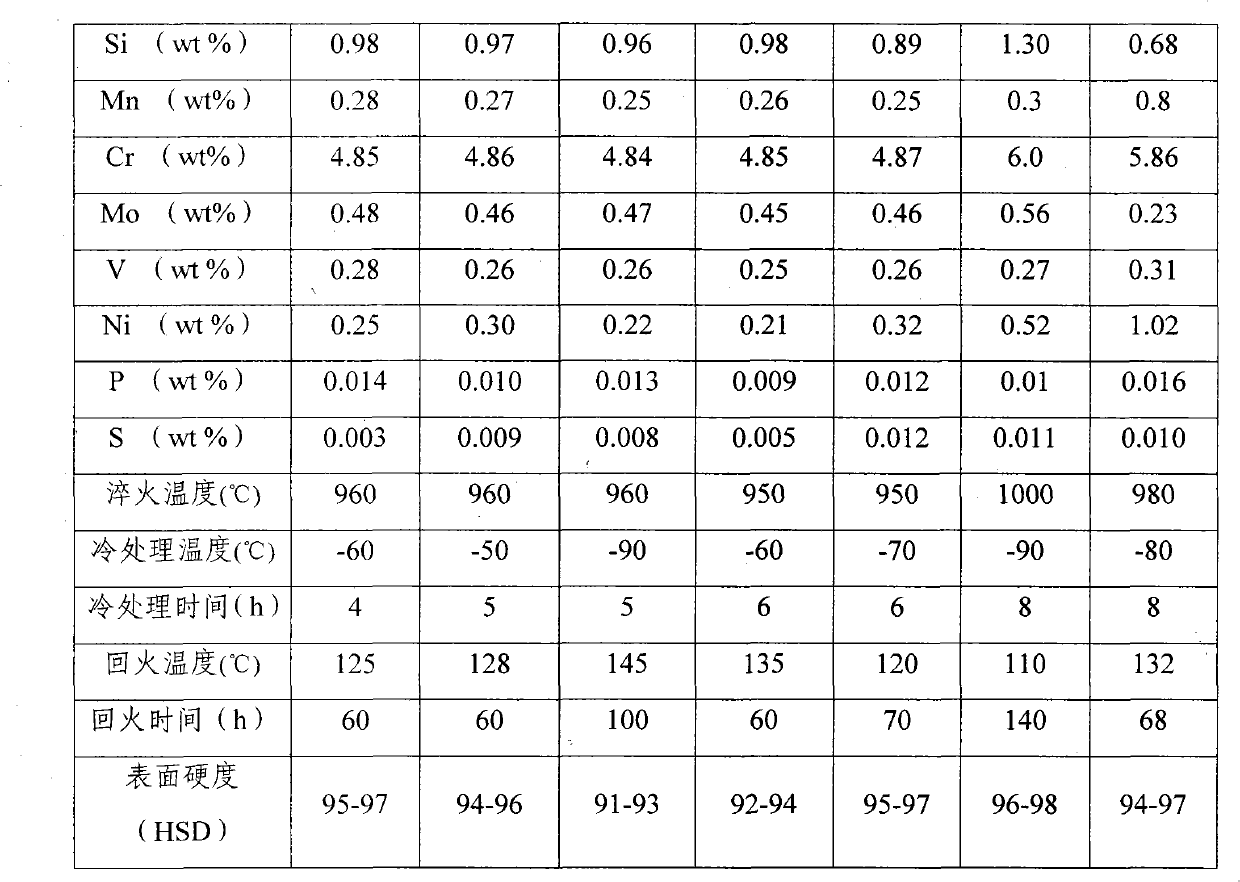

[0038] The manufacturing method of each embodiment is identical with embodiment 1, and the chemical composition and percentage composition and the surface hardness of finished product in process condition, cold roll material are shown in the table below:

[0039]

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com