Screw vacuum pump rotor profile

A technology of screw vacuum pump and rotor profile, which is applied in the direction of pumps, pump components, rotary piston pumps, etc., and can solve problems such as one-sidedness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

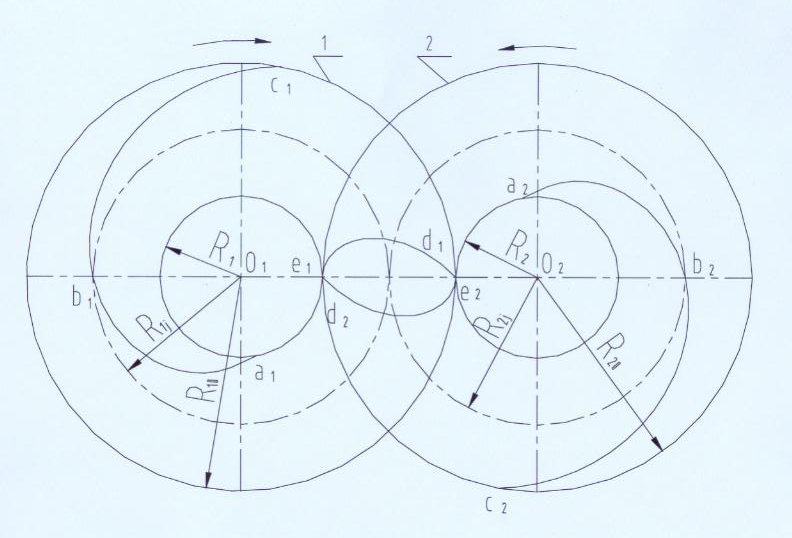

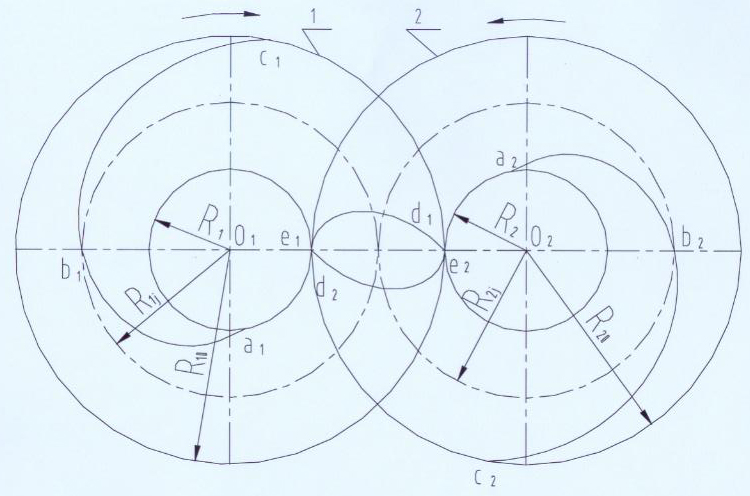

[0028] The construction of the profile line of the screw vacuum pump rotor end face of the present invention will be described in detail below with reference to the drawings and embodiments.

[0029] see figure 1 , The present invention provides a rotor profile of a screw vacuum pump, which respectively adopts five sections of curves to form the end surface profile of the first rotor 1 and the second rotor 2 . The profile series of the two rotors of the screw vacuum pump are formed by rotors with the same center distance A and different numbers of heads.

[0030] The profiles of the first rotor and the second rotor are composed as follows:

[0031] R 1 is the root circle radius of the first rotor, R 10 is the addendum circle radius of the first rotor.

[0032] R 2 is the radius of the dedendum circle of the second rotor, R 20 is the addendum circle radius of the second rotor.

[0033] R 1 =R 2 , R 10 =R 20 , pitch circle R 1j =R 2j =(R 1 +R 10 ) / 2.

[0034] b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com