Microchannel heat exchanger

A micro-channel heat exchanger and channel technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve problems such as insufficient heat exchange, and achieve sufficient heat exchange effect, sufficient heat exchange, and improved heat exchange. The effect of heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

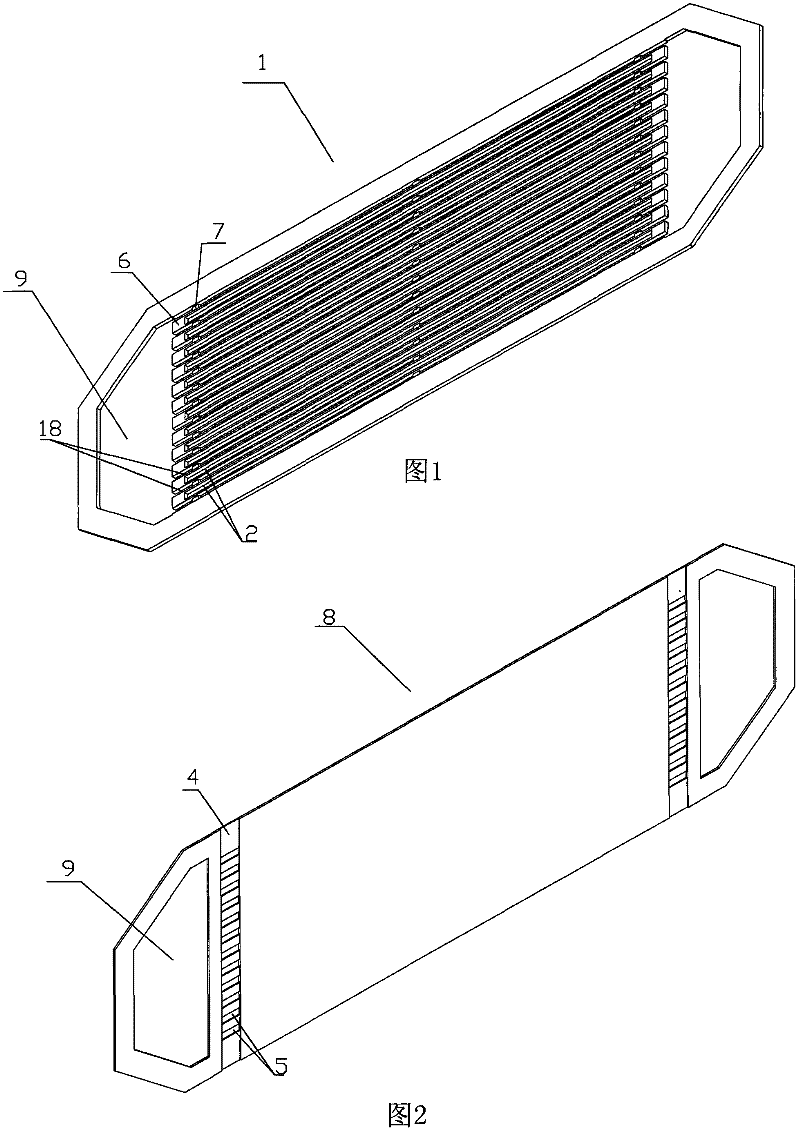

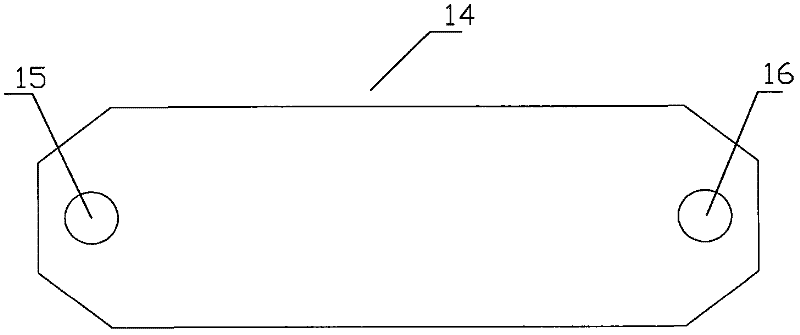

[0045] Such as Figure 1-7 As shown, a microchannel heat exchanger in Example 1 includes several heat exchange plates 1, and several spacers stacked with the heat exchange plates 1, wherein the stacked surface of the heat exchange plates 1 The first fluid channel 2 and the second fluid channel 18 are formed at intervals; the first fluid channel 2 is sealed at both ends along the length direction of the first fluid channel 2; the second fluid channel 18 is sealed along the The two ends of the second fluid channel 18 in the length direction are open; An extended transverse channel 4 , and the transverse channel 4 communicates with the first fluid channel 2 . The spaced arrangement of the first fluid channel 2 and the second fluid channel 18 on the same layer of the heat exchange plate 1 can realize the heat exchange on the same layer of the heat exchange plate 1, and the lateral direction on the separator The setting of the through groove 4 can not only provide the first fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com