Cylindrical transverse flux linear motor of zigzag ring winding structure

A technology of toroidal winding and transverse magnetic flux, applied in electrical components, electromechanical devices, electric components, etc., can solve the problem of long magnetic path of the mutual inductance effect magnetic field, and achieve the effect of simple structure, improved efficiency and reduced eddy current loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

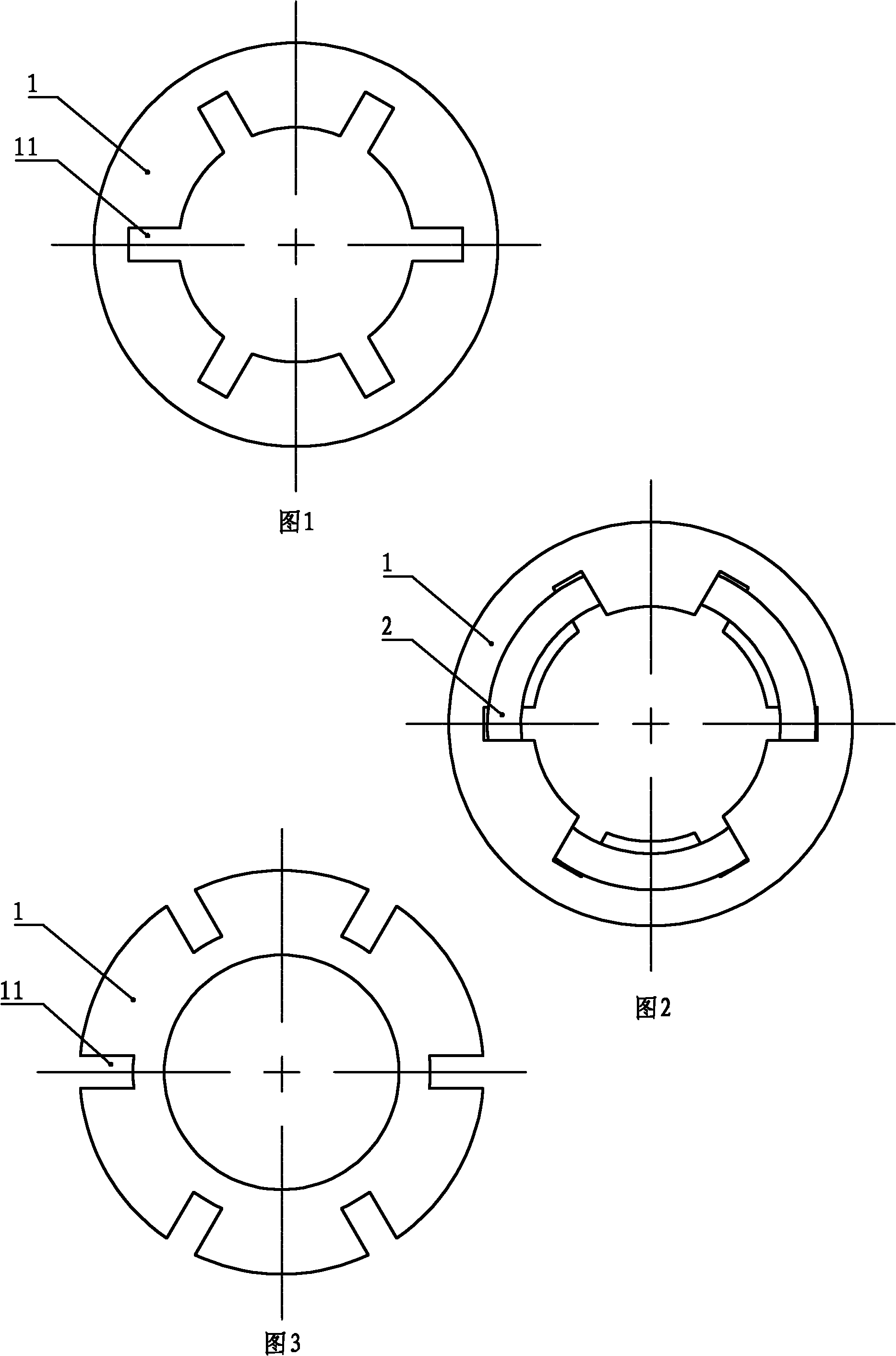

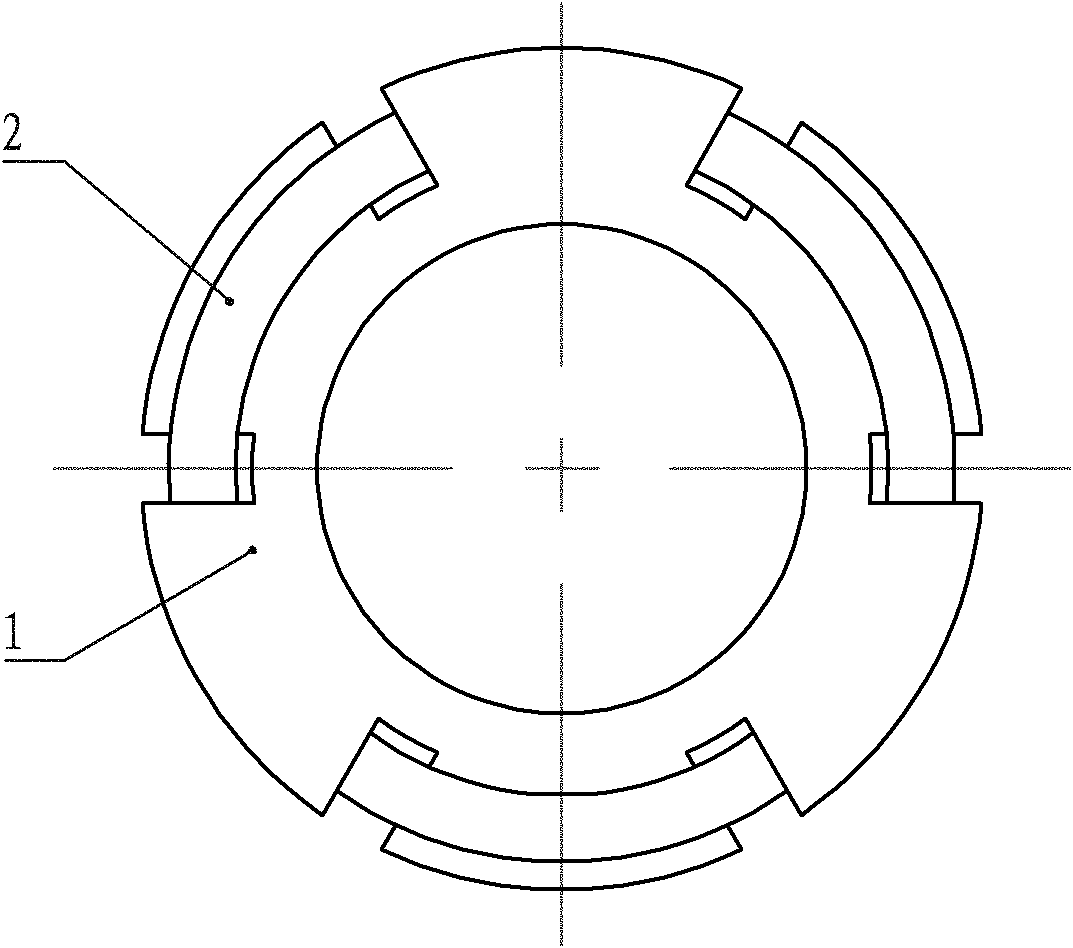

[0008] Specific implementation mode one: see figure 1 . The cylindrical transverse magnetic flux linear motor with meandering ring winding structure in this embodiment is composed of a primary, a secondary and an air gap. The primary includes a plurality of annular core units 1 and windings. The windings are composed of a plurality of coils 2. Its characteristics That is, there are 2n grooves 11 arranged in the radial direction on the air gap side of the annular core unit 1, where n is a positive integer, and the 2n grooves 11 are evenly distributed along the circumferential direction, and a plurality of annular iron cores The units 1 are evenly arranged inside the cylindrical casing along the axial direction, and there is a gap between every two adjacent annular core units 1 to form a slot for embedding coils. Each annular core unit 1 A coil 2 is wound on it, and the coil 2 is evenly divided into 2n effective segments 21 along the circumference, and between each two adjacen...

specific Embodiment approach 2

[0013] Embodiment 2: The main difference between this embodiment and the cylindrical transverse flux linear motor with meandering ring winding structure described in Embodiment 1 is that the stator core in the primary is cylindrical, and the multiple coils in the primary are 2 Evenly distributed along the circumferential direction and fixed on the air gap side of the stator core, the structure of the coil 2 is the same as that described in Embodiment 1. The specific structure of the linear motor described in this embodiment is: it consists of a primary, a secondary and an air gap , the primary includes an iron core and a winding, the winding is composed of a plurality of coils 2, and the plurality of coils 2 are evenly distributed in the axial direction and fixed on the inner surface of the cylindrical iron core, characterized in that the iron core is cylindrical , each annular meander coil 2 is composed of 2n effective segments 21 and 2n slot-spanning segments 22, wherein the ...

specific Embodiment approach 3

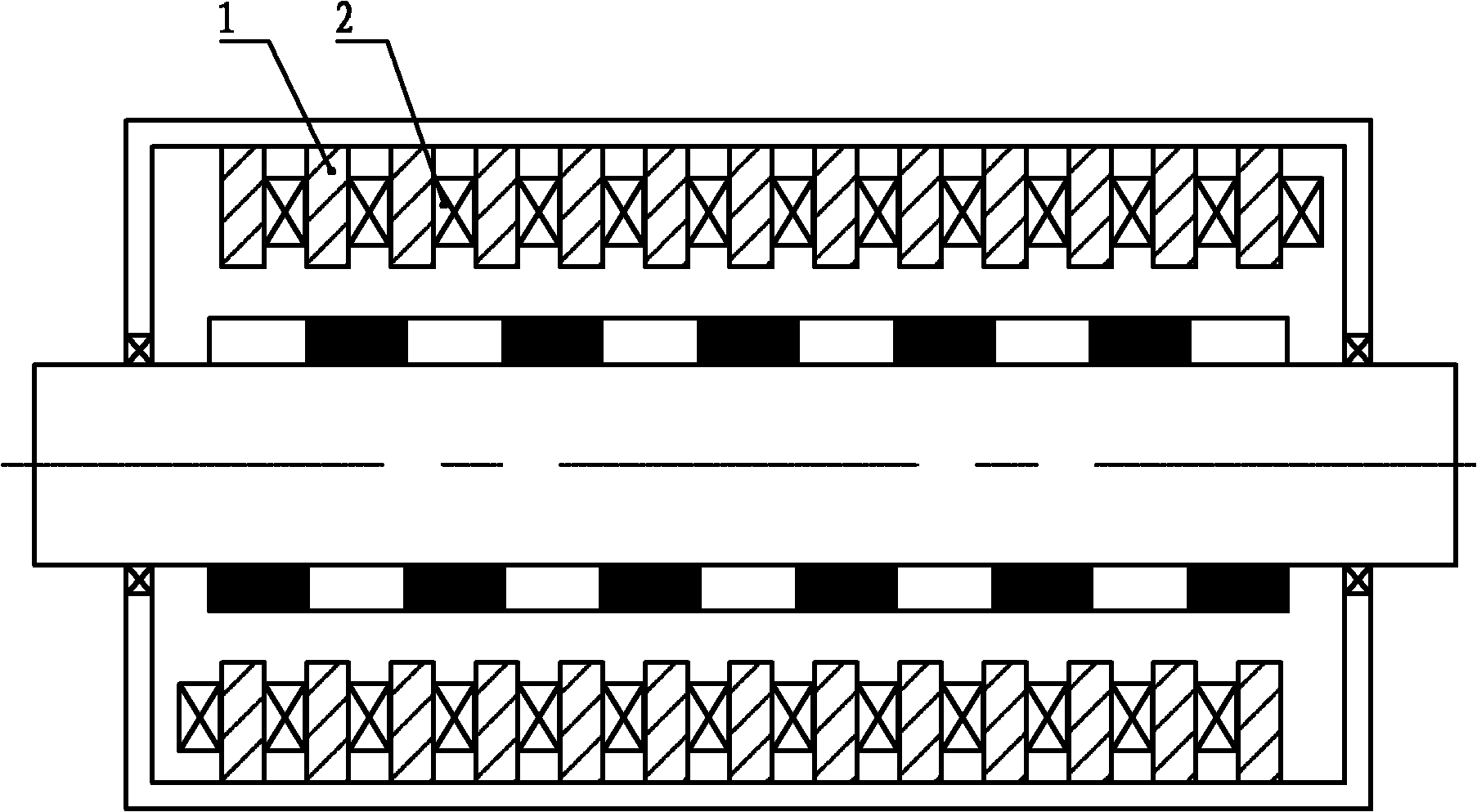

[0018]Specific embodiment three: this embodiment is a further definition of the secondary in the linear motor described in specific embodiment one or two, the secondary includes a permanent magnet array, and the specific structure of the permanent magnet array is: the permanent magnet The array is a cylindrical array structure composed of a plurality of tile-shaped permanent magnets 31. There are 2n tile-shaped permanent magnets 31 on each circumference, and each tile-shaped permanent magnet 31 is radially magnetized, and each tile The magnetization direction of the tile-shaped permanent magnet 31 and its axially adjacent and circumferentially adjacent tile-shaped permanent magnets 31 are all different.

[0019] When n=3, the expanded view of the permanent magnet array described in this embodiment can be found in Figure 10 As shown, the number of rows of the permanent magnet array along the axial direction can be determined according to actual needs, Figure 10 Shown is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com