Monitoring of frying oil quality using combined optical interrogation methods and devices

An optical interrogation and optical technology, applied in measuring devices, analysis using chemical indicators, material analysis through optical means, etc., can solve the problem that the free fatty acid test and the total polar compound test are not completely independent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0096] Test strips were obtained, available from 3M Company under the trade designation 3M Shortening Monitor Test Strips, and believed to be manufactured in a manner similar to that described in US Pat. No. 4,654,309 (Example 4).

[0097] An edible oil was obtained with a composition of about 40% sunflower oil (minimum 70% oleic acid), about 30% palm oil and about 30% hydrogenated rapeseed oil (all percentages by weight). The cooking oil was used to cook the fried potatoes for about two months, during which time small samples were taken from the oil periodically.

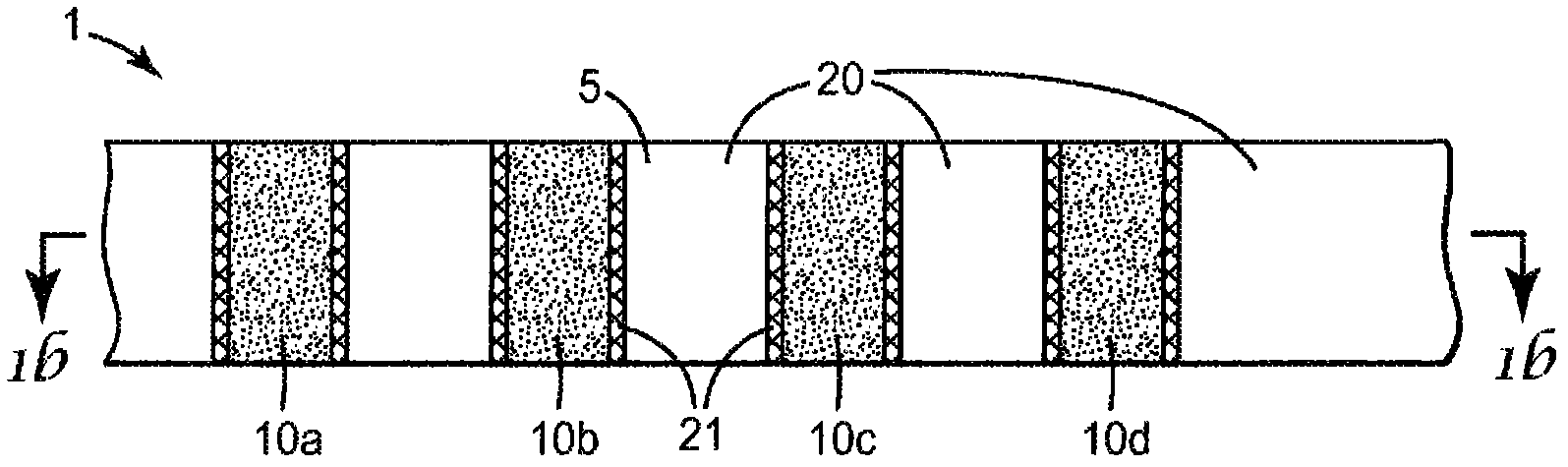

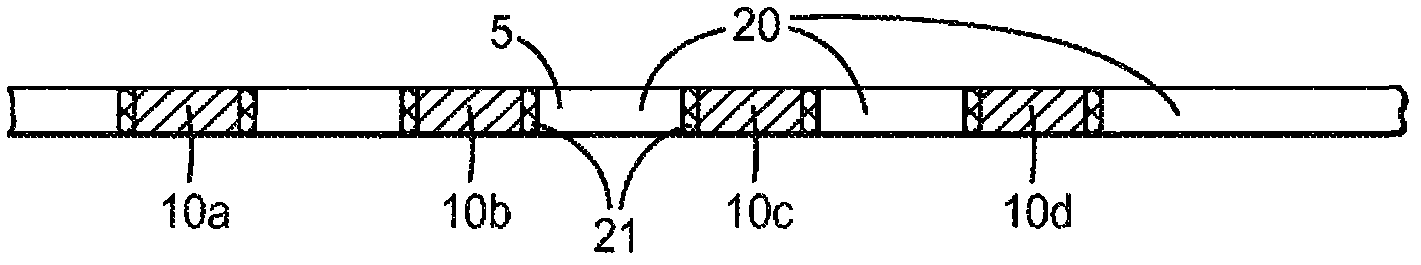

[0098] Test samples according to the following procedure. Since most samples are solid at room temperature, each sample (150 cc in a plastic jar) was heated in a microwave for 60 seconds, or until the sample melted into a liquid. The test strip is then dipped into the oil sample and placed on a paper towel to remove excess oil. Each of the four test areas of the test strip (i.e., the area that appeared blue when ...

example 2

[0103] Test strips were obtained, available from 3M Company under the trade designation 3M Shortening Monitor Strips, and believed to be manufactured in a manner similar to that described in US Patent 4,654,309 (Example 4).

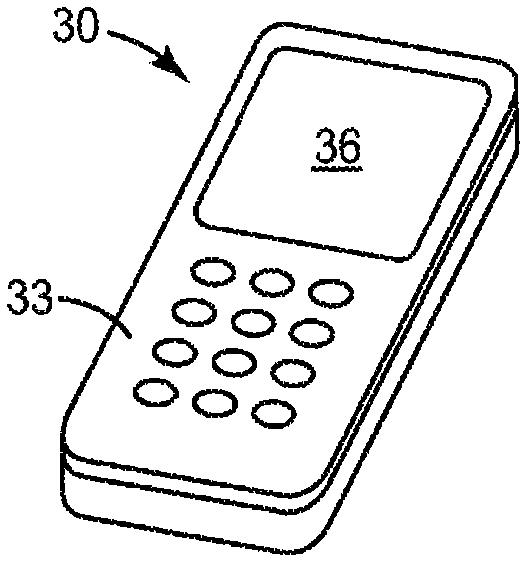

[0104] Four photodetector photodiodes (Si PIN type) were obtained from Hamamatsu Photonics (Hamamatsu City, Japan) under the trade designation S9345. The individual photodiodes are identified as PD-0, PD-1, PD-2, and PD-3.

[0105] Light emitting diodes (ultra white (GaN) type) were obtained from SuperBright LEDs, Inc (St. Louis, Missouri) under the trade designation RL5-W5020.

[0106] Test strips were obtained, available from 3M Company under the trade designation 3M Shortening Monitor Strips, and believed to be manufactured in a manner similar to that described in US Patent 4,654,309 (Example 4).

[0107] The test areas of each test strip were exposed to oil samples having a "low" content of free fatty acids; that is, levels that did not cause a visua...

example 3

[0112] Test strips were obtained, available from 3M Company under the trade designation 3M Shortening Monitor Strips, and believed to be manufactured in a manner similar to that described in US Pat. No. 4,654,309 (Example 4).

[0113] An edible oil was obtained with a composition of about 40% sunflower oil (minimum 70% oleic acid), about 30% palm oil and about 30% hydrogenated rapeseed oil (all percentages by weight). The cooking oil was used to cook the fried potatoes for about two months, during which time small samples were taken from the oil periodically.

[0114] Samples were tested as follows. Since most samples are solid at room temperature, each sample (150 cc in a plastic jar) was heated in a microwave for 60 seconds, or until the sample melted into a liquid. The test strip was then dipped into each oil sample and placed on a paper towel to remove excess oil. Fluorescence measurements were performed on each oil-containing "blank" area of the test strip (i.e., the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com