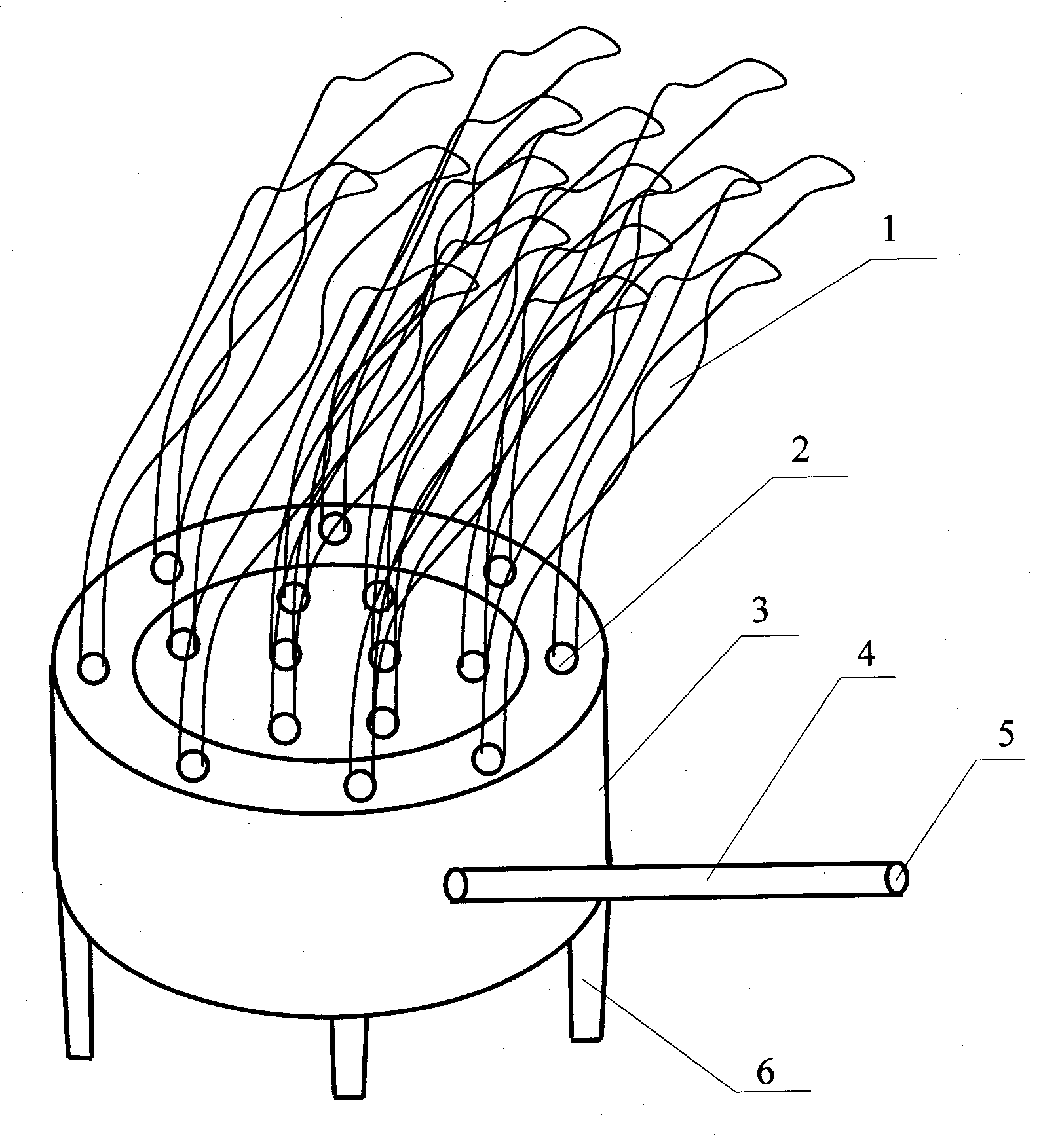

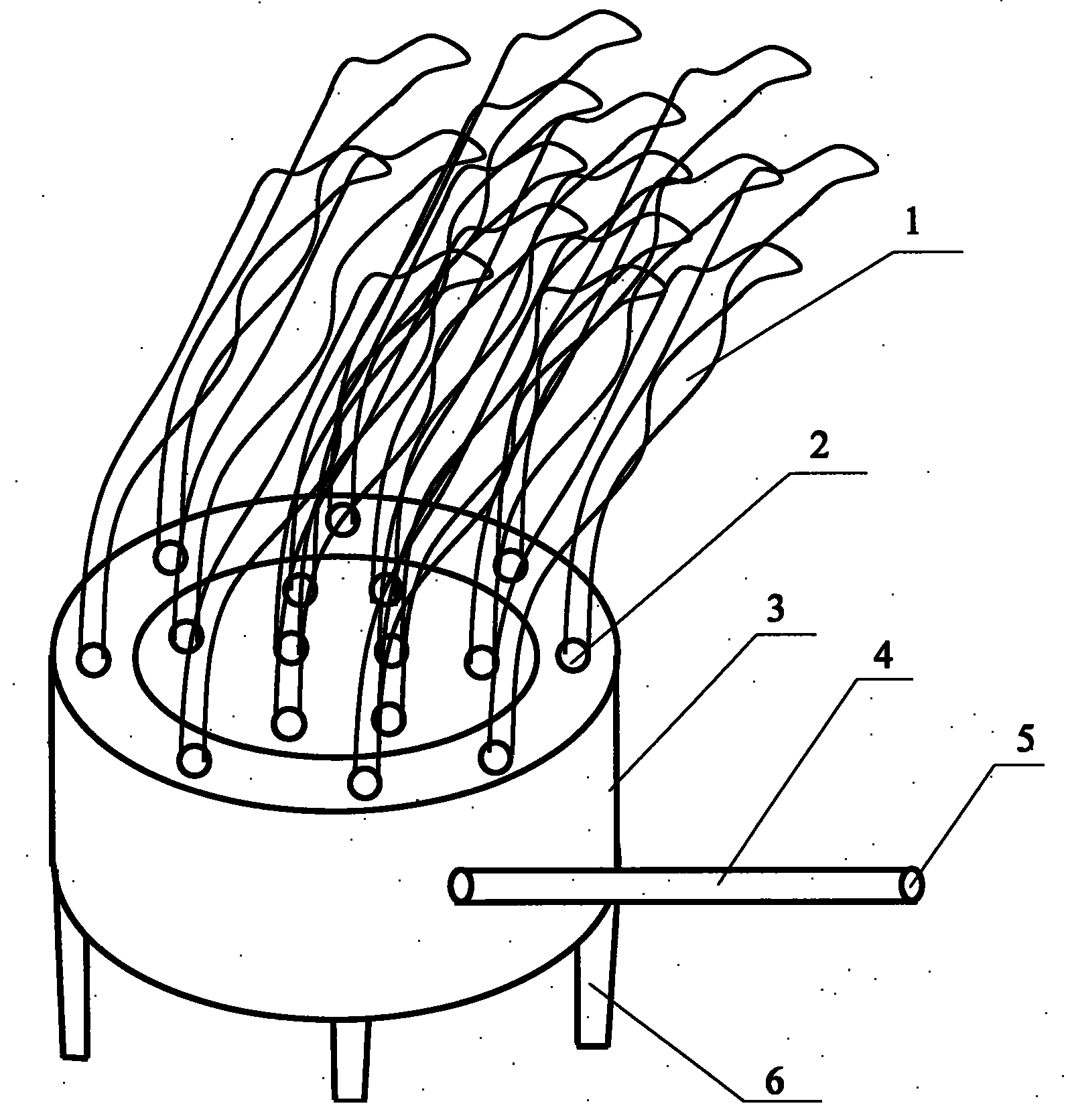

Fire drill brazier

A fire drill and brazier technology, applied in fire rescue and other directions, can solve the problems of polluted air, difficult to clean, high fuel consumption, etc., and achieve the effects of low cost, oil saving and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is composed of red cloth strip 1, hole 2, basin body 3, air inlet pipe 4, air inlet port 5 and feet 6, and is characterized in that the basin body 3 is provided with an air inlet pipe 4, and there is a hole 2 at the mouth of the basin, and the hole 2 is connected to the red cloth strip 1, and there is a foot 6 under the basin body 3. During the exercise, continuous compressed air is sent from the air inlet 5, and the air flow drives the red cloth strip 1 to flow from the hole 2, achieving the rendering of the red flame on the spot Atmosphere, firefighters spray fire extinguishing agent towards the fire drill brazier of the present invention with a fire extinguisher. After the fire extinguishing agent is sprayed on the red cloth strip 1, it will be in a wet state, and the compressed air flow cannot blow the red cloth strip 1. success purpose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com