Recording apparatus and driving control method thereof

一种记录装置、驱动辊的技术,应用在打印装置、印刷、打字机等方向,能够解决保持托盘供给量变动、缩小等问题,达到良好图像形成的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, in each of the drawings used in the following description, the scale of each member is appropriately changed in order to make each member recognizable.

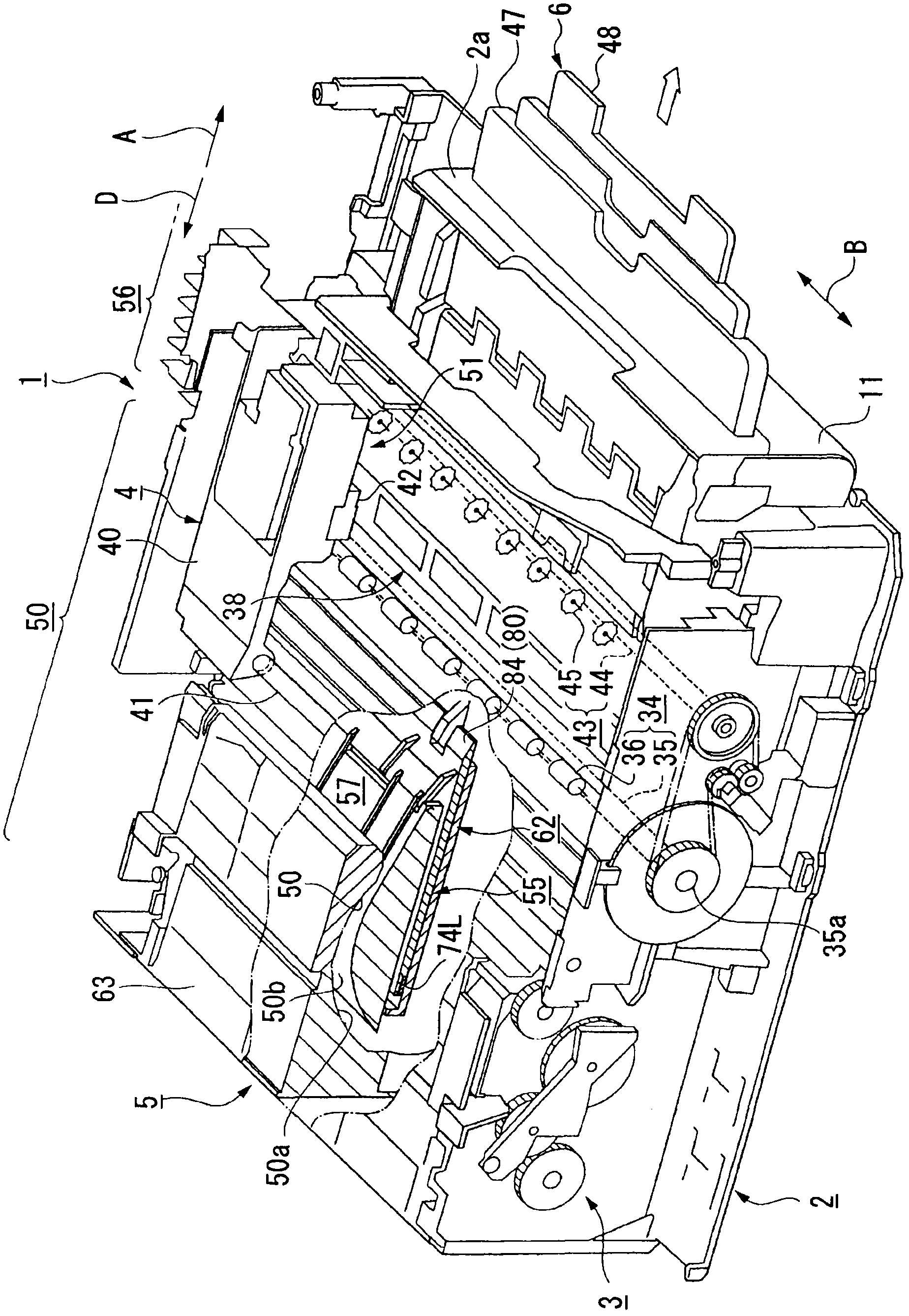

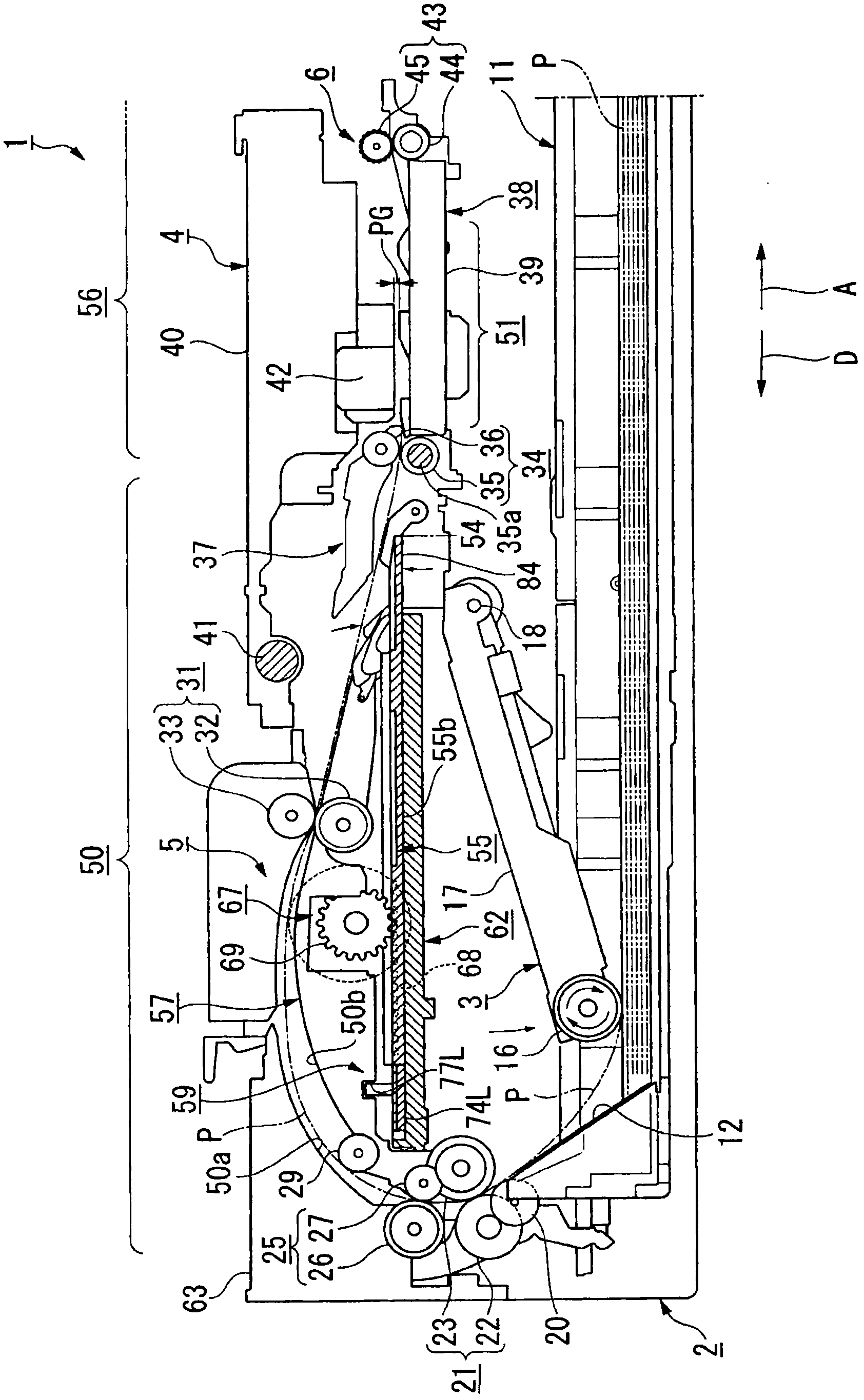

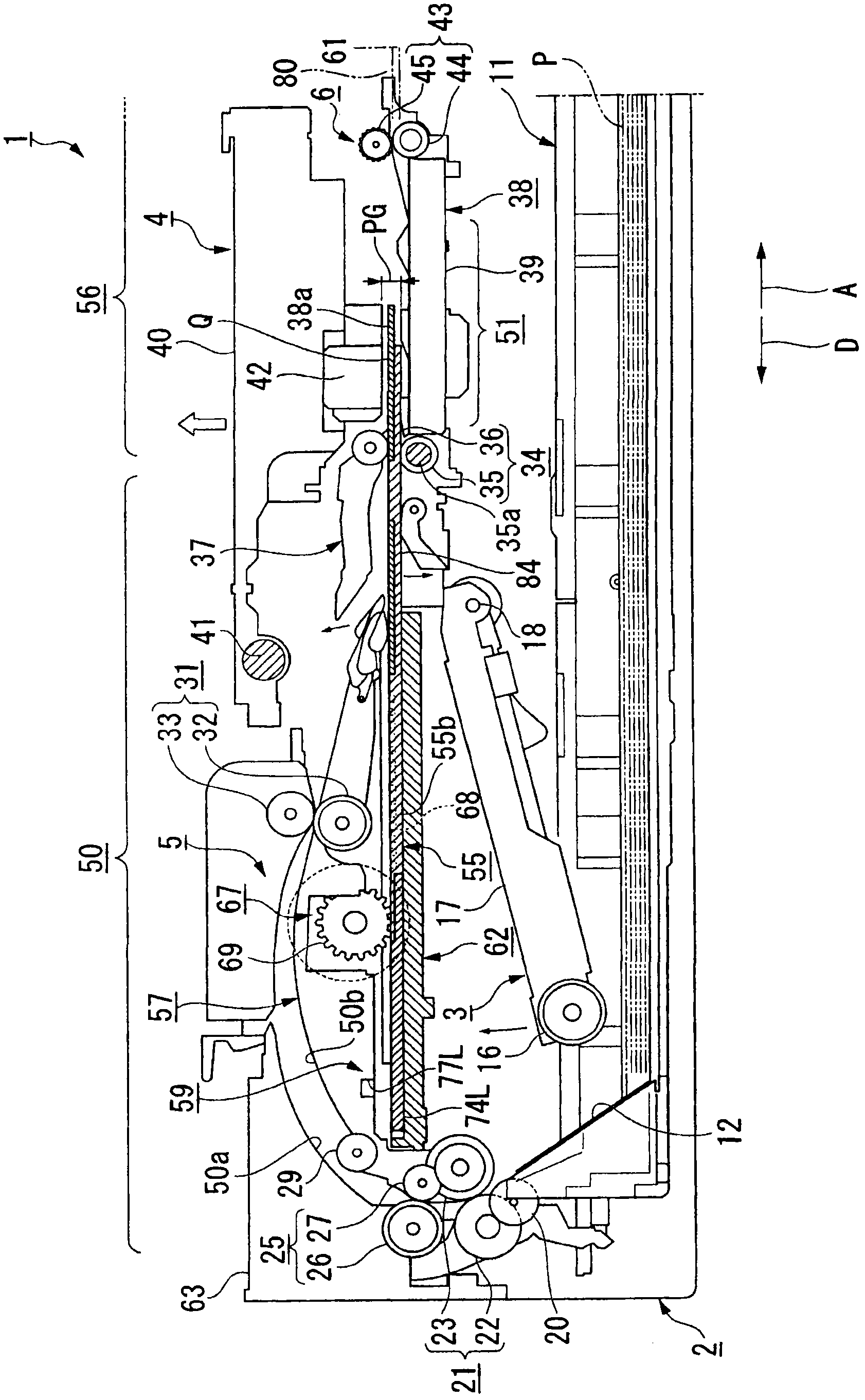

[0042] figure 1 is a perspective view overall showing the internal structure of the inkjet printer, figure 2 It is a schematic block diagram showing the structure of the inkjet printer, that is, a side sectional view when the holding tray is at the storage position, image 3 It is a side sectional view when the pallet is kept at the record execution start position (end position), Figure 4 is a side sectional view with the pallet held in the placement position.

[0043] In addition, the illustrated inkjet printer 1 is a composite type inkjet printer equipped with an unillustrated image reading device (scanner) on the upper part, and is capable of performing a paper, film, or other soft recording medium P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com