Apparatus for testing rock drillability under stratum condition

A technology of stratum conditions and testing instruments, which is applied in the direction of earthwork drilling and production, wellbore/well components, etc., can solve problems such as large measurement errors, missing, sealing failure of seals, etc., and achieve the effect of improving measurement accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

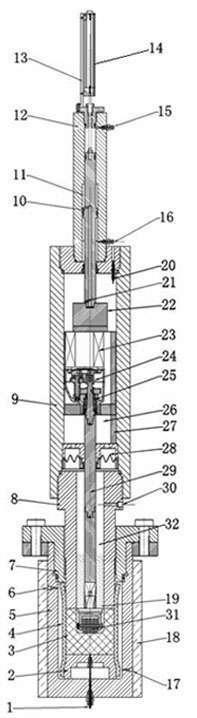

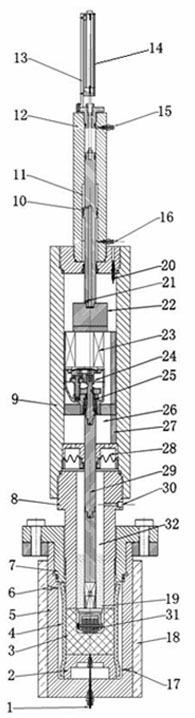

[0020] see figure 1 The present invention comprises a clamping mechanism, a pressure balance mechanism and a power mechanism, the clamping mechanism, the pressure balance mechanism and the power mechanism are interrelated and rely on each other, the clamping mechanism is arranged at the lower end of the pressure balance mechanism, and the power mechanism is arranged at the pressure balance mechanism and the clamping mechanism. within the holding institution.

[0021] The clamping mechanism is composed of a holder kettle body 5, a taper sleeve 7, a rubber sleeve 4, an upper plunger 8 and a lower plunger 2, and a heater 18 is installed on the outer circumference of the holder kettle body 5, and the heater 18 is controlled by temperature. The controller controls the temperature of the holder body to simulate the formation high temperature. The rubber sleeve 4 and the lower plunger 2 are sequentially arranged in the holder body 5, the lower plunger 2 is arranged at the inner bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com