Method and device for recognizing a state of a noise-generating machine to be studied

A noise and state technology, which is used in the field of state identification and devices for machines to be inspected that generate noise, can solve the problems of different noise signals or acoustic emission, noise signal deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

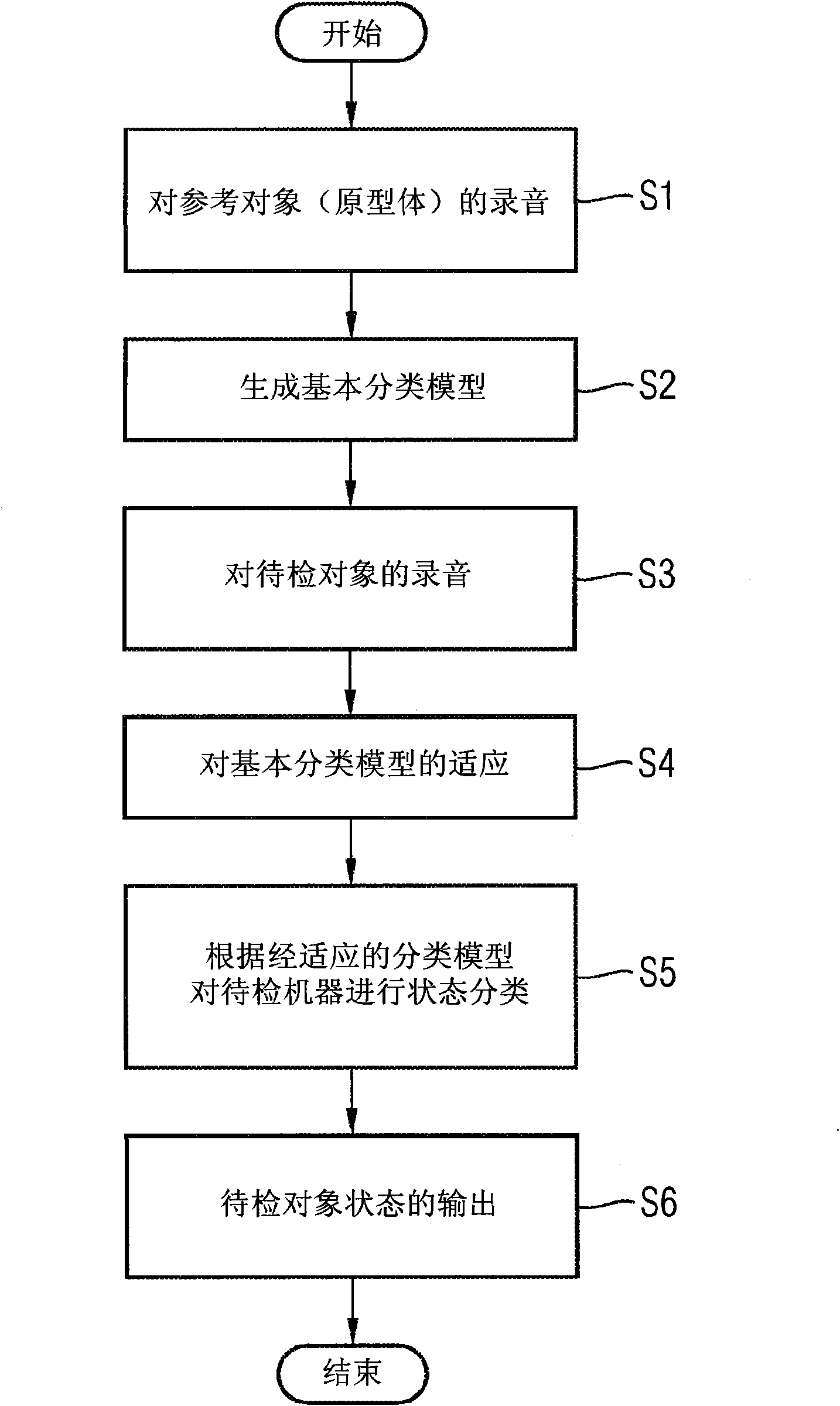

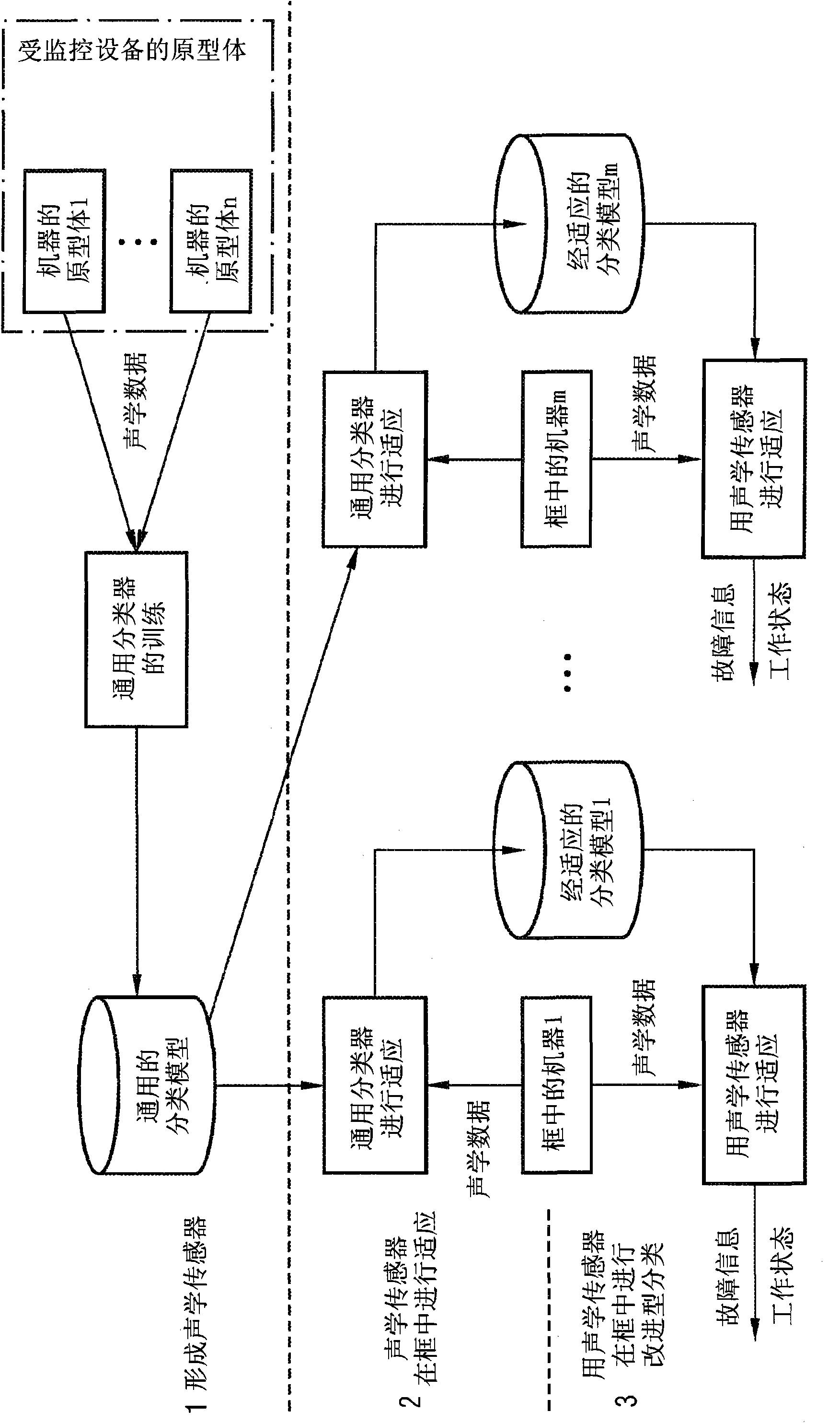

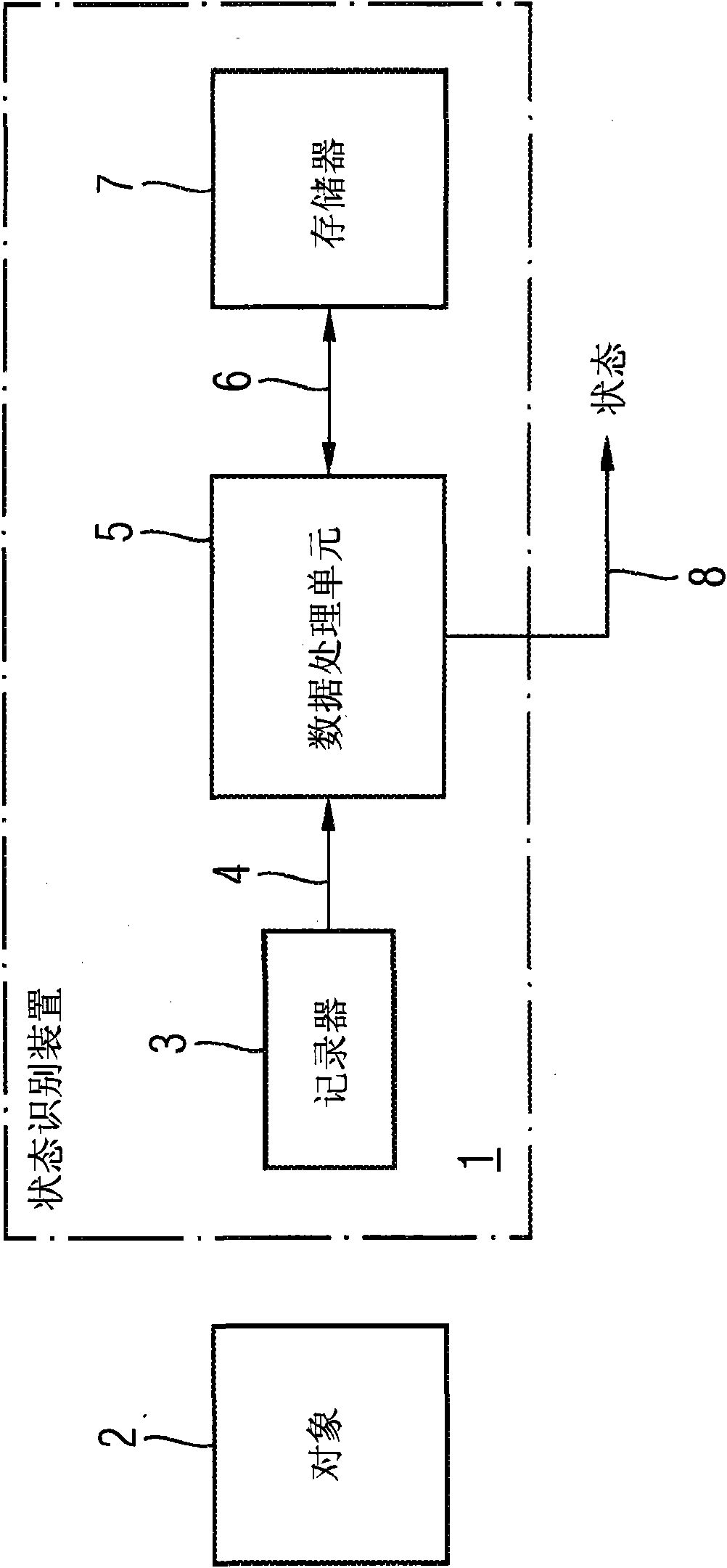

[0028] From figure 1 It can be seen that, in step S1 of the method of the present invention, firstly, a reference object of the object to be inspected that generates noise is recorded by means of a recorder or a sensor. The reference object may refer to a prototype of the object to be checked. The object to be checked is, for example, a machine or a device that generates noise during operation. The noise signal may be an air noise signal or a structure noise signal. The device to be tested can also be a device, such as a chemical device that generates noise during its chemical production, for example inside a container or a pipeline. Noise and vibration signals are recorded by a recorder. These recorders have microphones or other vibration sensors, especially accelerometers. The recorder or vibration sensor converts noise or vibration signals into electrical signals. Preferably multiple recordings are made of a reference or prototype body at different time points and unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com