Ribbed structure of ribbed tube molding mould

A technology of reinforced pipes and reinforcing ribs, which is applied in the field of reinforced pipe forming modules, can solve the problems of skin tearing, physical properties, decline, etc., and achieve the effect of uniform appearance, smooth surface and improved physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

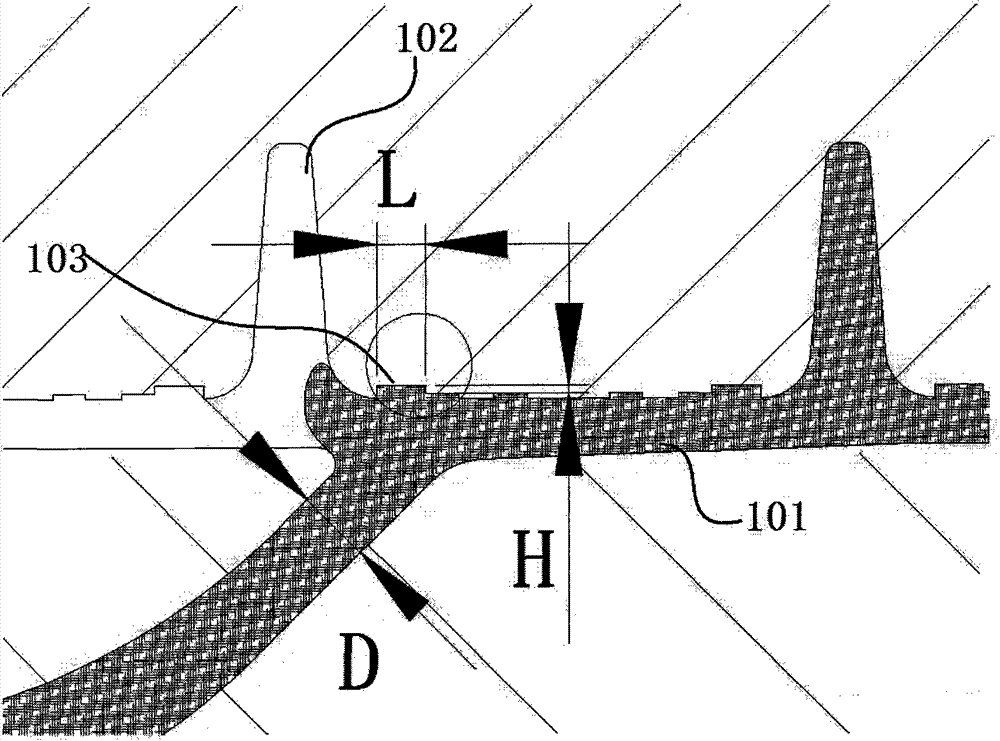

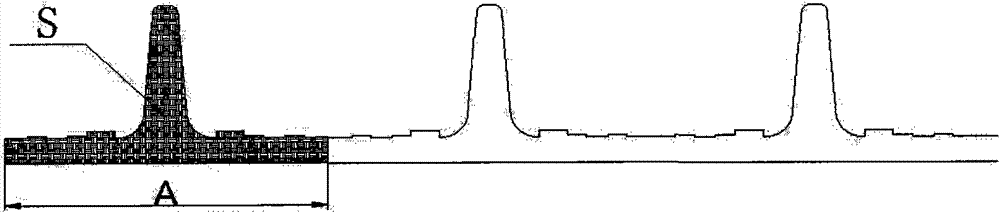

[0025] The present invention adds two small ribs on the molding module through the analysis and calculation of the pressure change and material distribution in the molding process, so that the influence of the extrusion pressure on the filling of the ribs is reduced, and the surface tearing caused by the secondary filling is avoided. The problem is that after the modification of the ribbed structure of the module, the appearance of the pipe is uniform, the surface is smooth, and there is no tearing phenomenon, and the physical properties of the pipe have also been greatly improved.

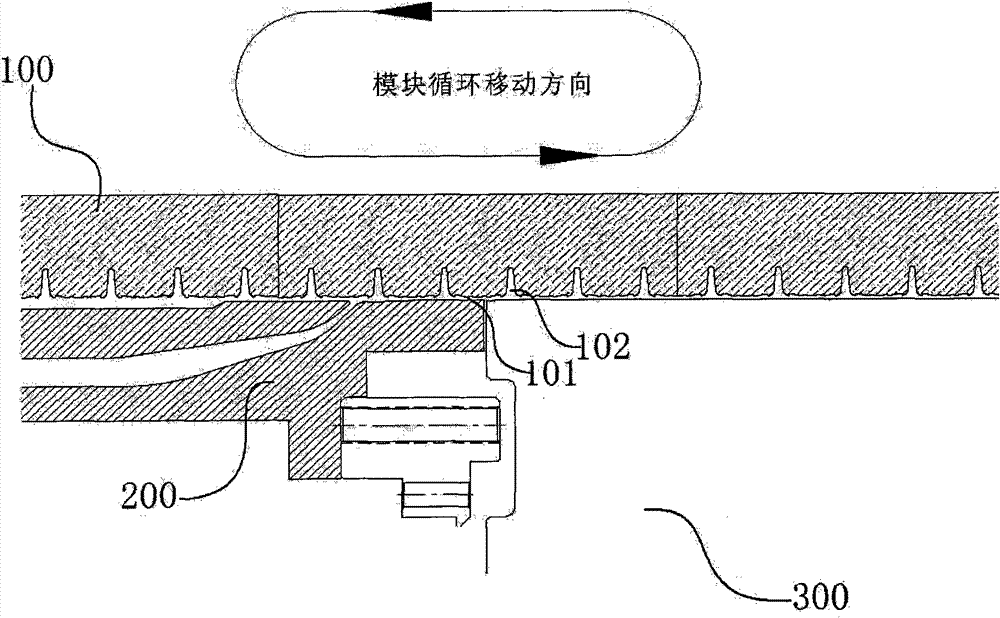

[0026] Based on the above principles, the overall structure of the present invention is as follows: figure 1 As shown, a rib-shaped structure on a reinforced pipe m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com