Method for embedding sample into oxidation layer on inner wall of heated surface pipe

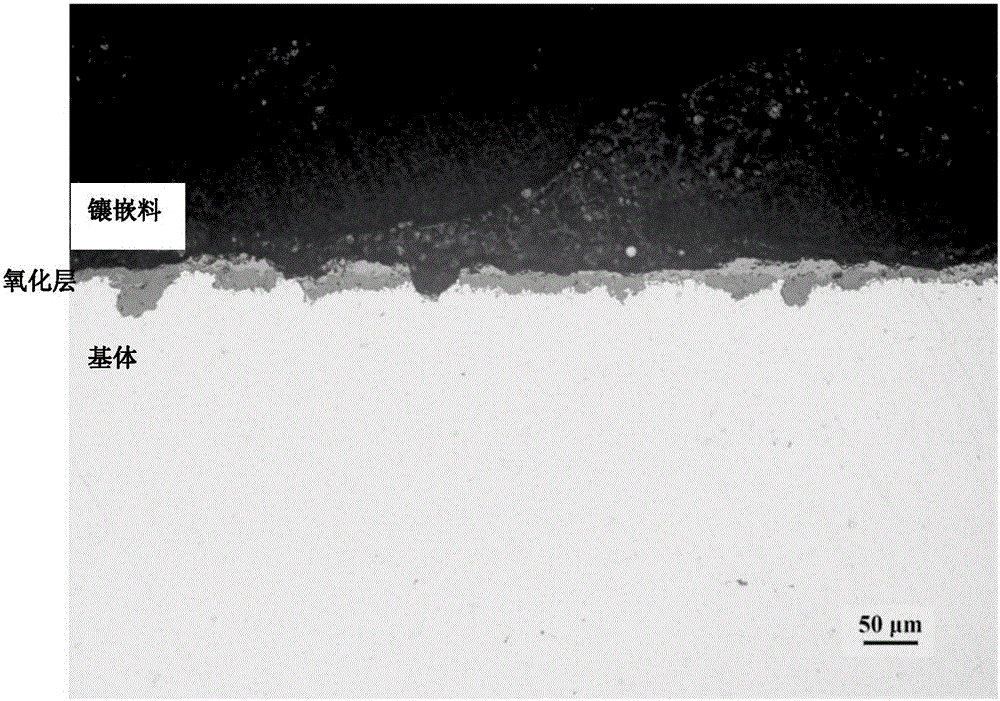

A heating surface tube, oxide layer technology, applied in the preparation of test samples, etc., can solve the problems of the thickness of the oxide layer structure cannot be observed, the combination of the inner wall oxide layer and the tube wall is weak, and the failure of the mosaic sample, etc. The effect of procedures for easy grinding and polishing, good thickness, and reduced demolding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0036] A method for inlaying a sample of an oxide layer on the inner wall of a heating surface tube of the present invention comprises the following steps:

[0037] 1) Preparation of mounting material

[0038] Weigh 60g of E-44 epoxy resin in a beaker, add 7g of diluent to the epoxy resin at room temperature, stir well to mix the diluent into the resin, then add 55g of curing agent, mix well and use it as an inlay spare.

[0039] 2) Preparation of samples to be tested

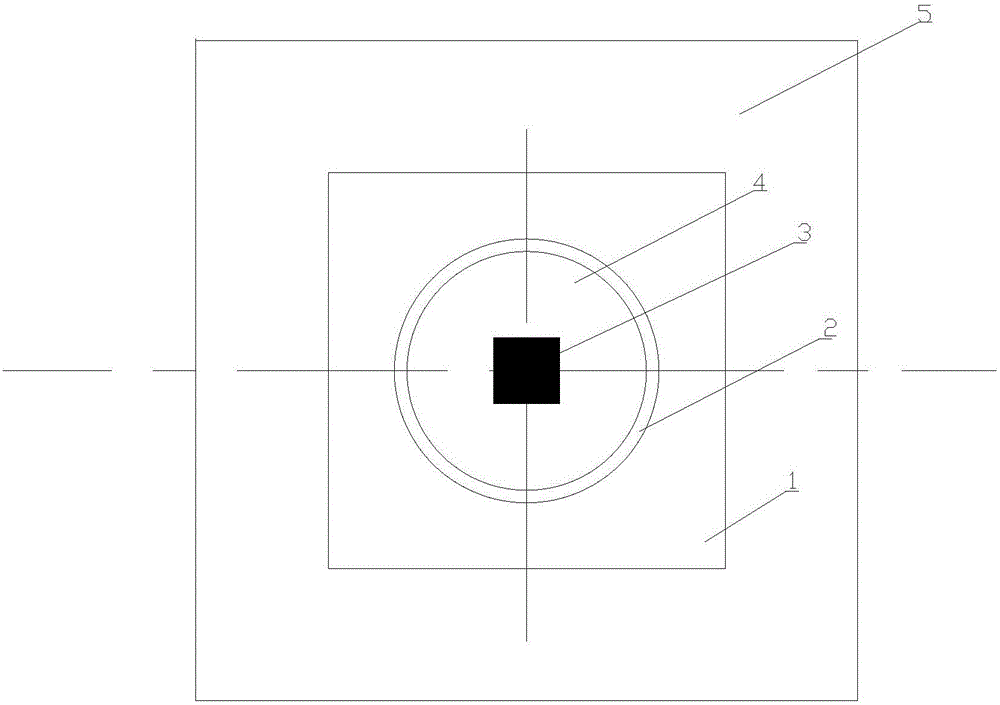

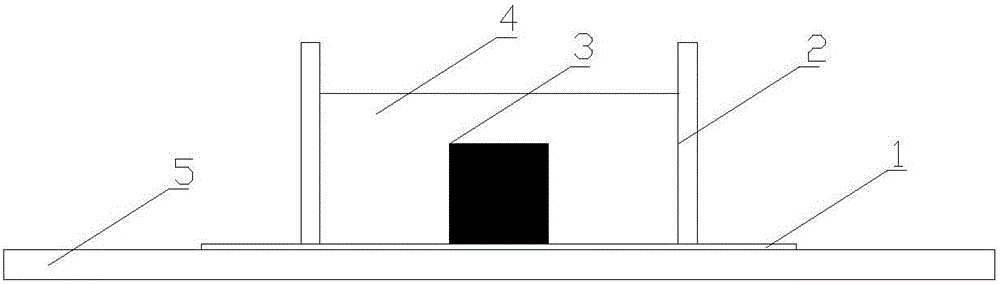

[0040] Cut the sample to be tested into small pieces. The sample size is: length 10mm, width 10mm, height 10mm. Put the glass flat plate 5 flat, place the weighing paper 1 on the glass flat plate 5, then place the 3 small pieces of the sample to be tested face down on the weighing paper 1, and then use the circular PVC pipe section 2 to cover the On the outside of the test s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com